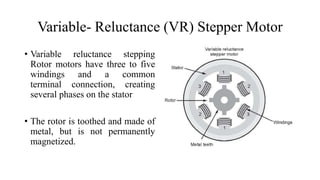

Actuators transform controller outputs into physical motions or actions. Common actuators include solenoids, motors, and cylinders. Actuators can be classified as pneumatic, hydraulic, or electrical. Stepper motors convert electrical pulses into discrete rotational movements. Variable reluctance stepper motors have windings that create magnetic fields to attract the toothed rotor and cause it to rotate in small angular increments with each pulse.