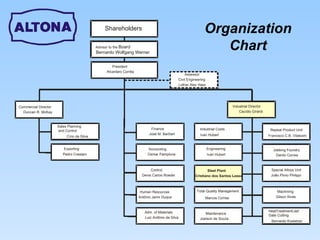

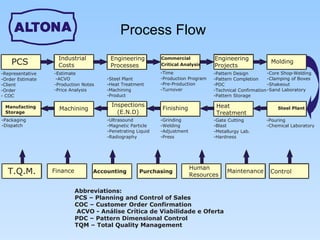

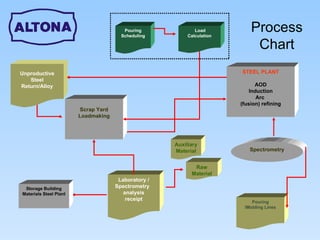

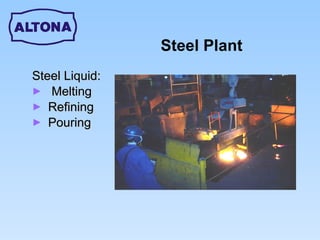

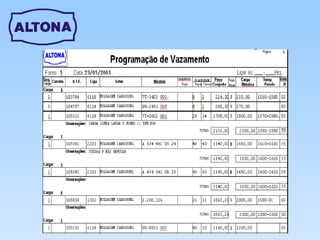

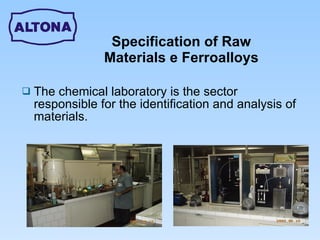

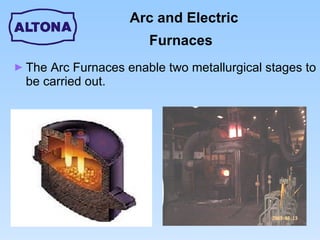

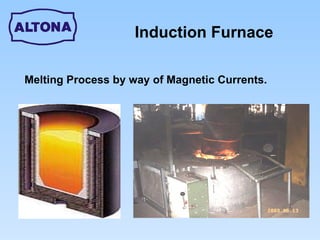

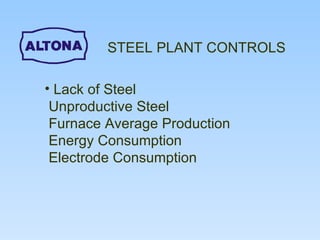

The document outlines the organizational chart and production processes of an engineering steel plant. It details the roles of leadership positions like the president and directors. It maps the flow of raw materials from storage through melting, refining, alloying and pouring processes. Key stages include loading scrap and alloys, melting in electric arc furnaces, secondary refining using AOD converters, heating ladles, and final pouring of liquid steel. Laboratories analyze raw materials and samples to control quality.