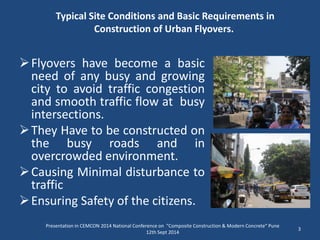

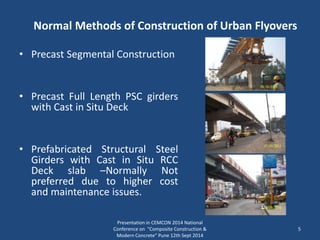

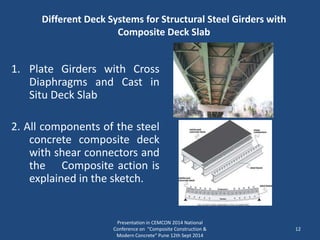

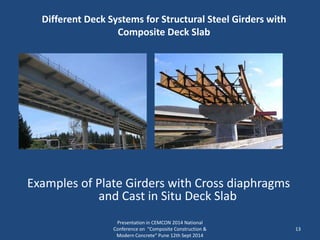

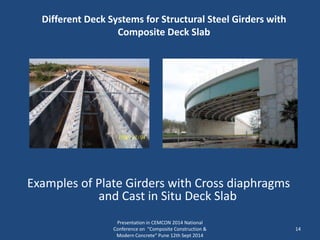

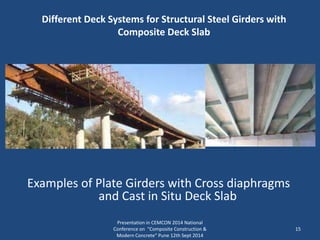

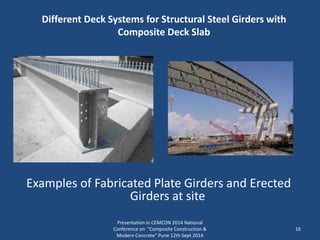

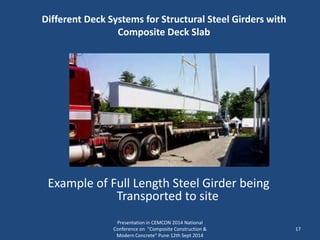

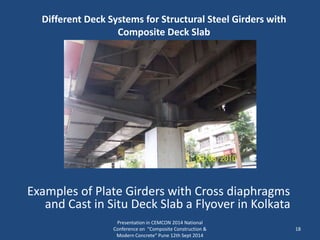

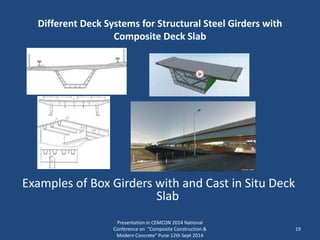

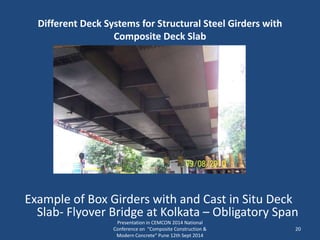

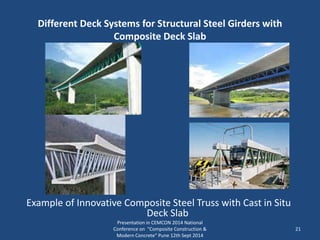

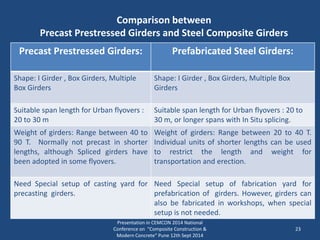

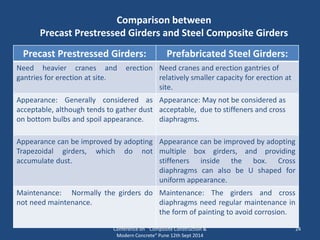

This document discusses the use of prefabricated structural steel girders with composite reinforced concrete deck slabs for the construction of urban flyovers. Some key advantages of this system include reduced girder weights which allows for transportation and erection with smaller equipment, and the ability to construct longer obligatory spans by splicing shorter girder units together on site. Several deck systems are presented, including plate girders with cross diaphragms and cast-in-place slabs. The document concludes that while less common in India due to cost and maintenance needs, prefabricated steel girder systems can offer construction benefits for narrow urban sites.