The document discusses steam turbines, including:

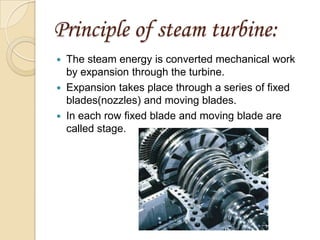

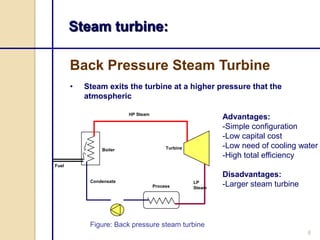

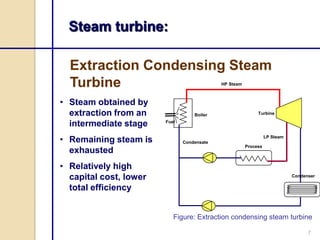

1) A steam turbine converts the energy of steam into rotational mechanical energy through expanding steam in a series of fixed and moving blades.

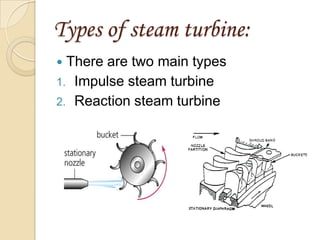

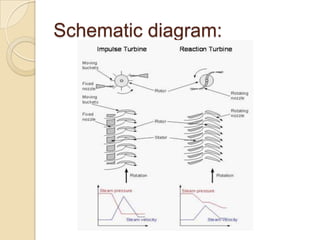

2) The two main types are impulse turbines, where steam pushes against rotor blades from a nozzle, and reaction turbines, where steam flows through both fixed and moving blades.

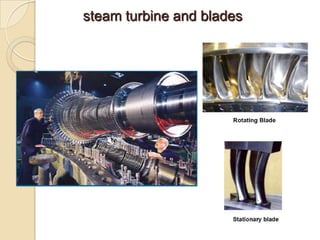

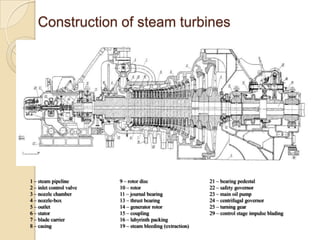

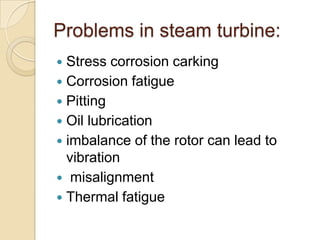

3) Key components include the casing, rotor, blades, valves, bearings, and gearbox. Common problems include stress corrosion cracking, corrosion fatigue, and thermal fatigue of blades.