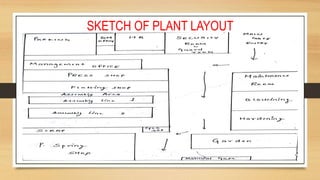

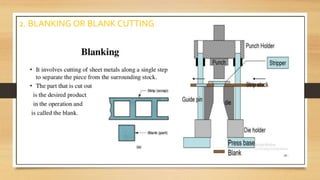

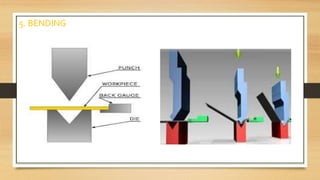

This training report provides information about Kangaro Industries Ltd, a leading manufacturer of stationery products in India. It discusses the company's history and achievements, including receiving the World Quality Commitment Award. It also outlines the key processes involved in manufacturing the products, describing the main plants for press work, spring coiling, plating, painting, and assembly. Diagrams are included showing the plant layout and workings of the spring coiling machine. The report aims to provide details about Kangaro Industries' manufacturing operations and quality recognition.