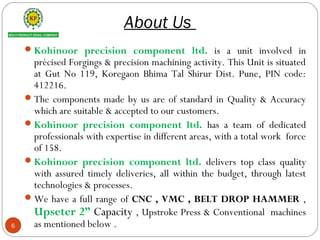

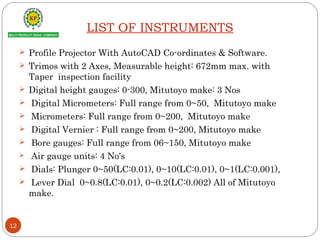

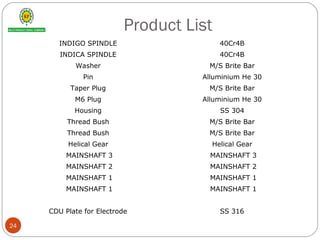

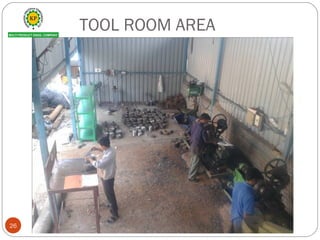

Kohinoor Precision Component Ltd. specializes in manufacturing precision machined components and forgings for the automotive industry, adhering to ISO 9001:2008 and TS 16949 standards. The company is committed to delivering high-quality products on time while maximizing customer satisfaction through efficient operations and modern equipment. They have a skilled workforce and use advanced technologies in their machining and forging processes.