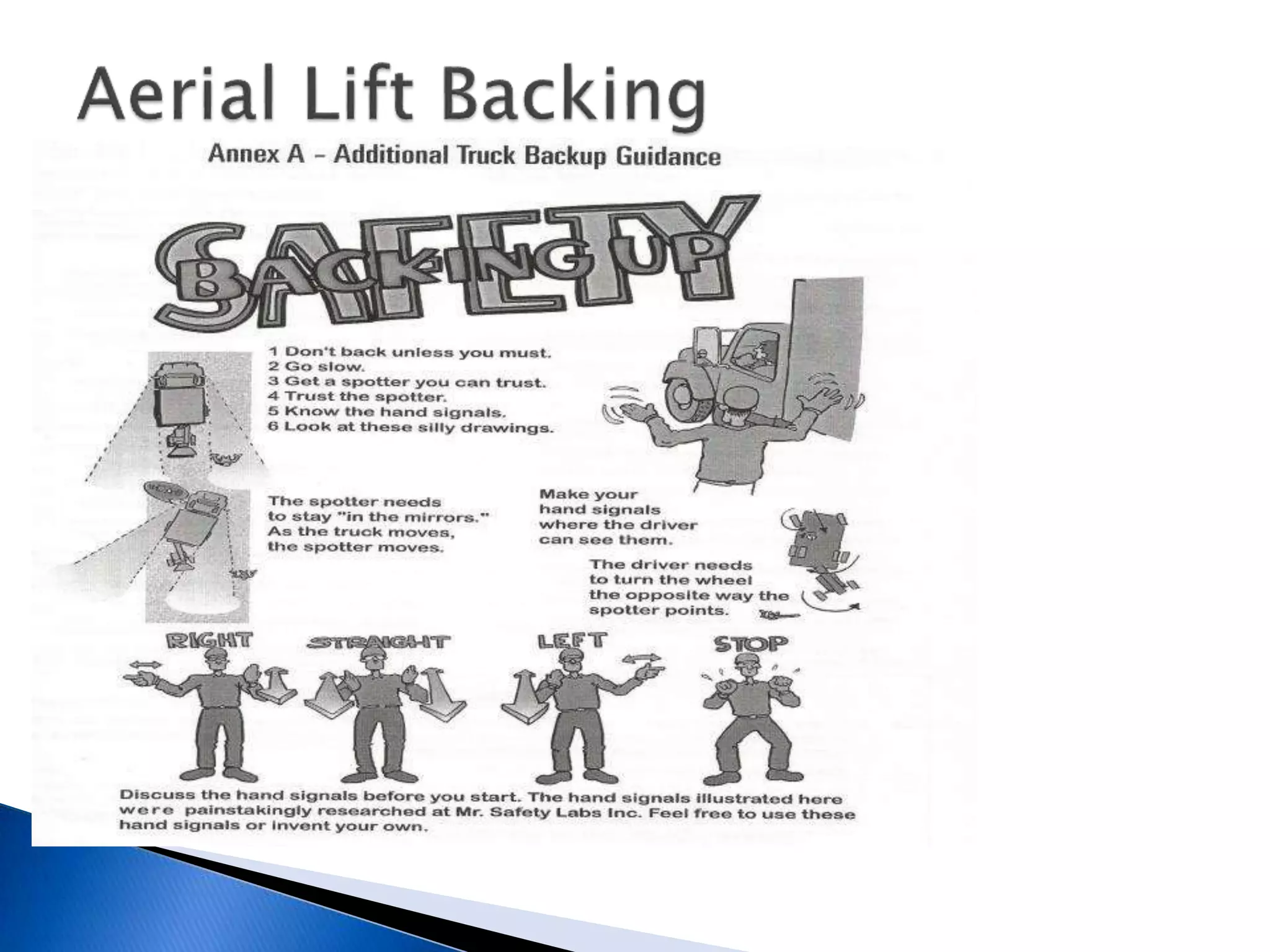

This document provides training on safety procedures for operating aerial lifts. It defines an aerial lift as any work platform with an articulating boom and bucket. Only qualified employees can operate lifts after certification. The training covers common accident types, safety sign meanings, required personal protective equipment, inspection procedures, operation guidelines, and safety standards to follow when working near power lines. Trainees learn to identify hazards, set up the lift properly, and control traffic at worksites.