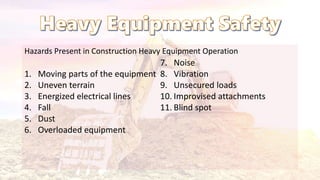

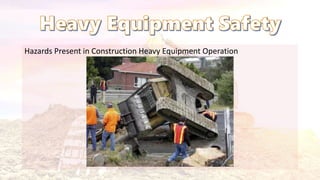

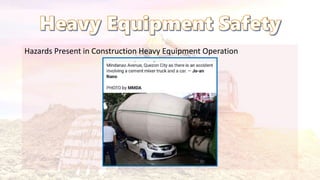

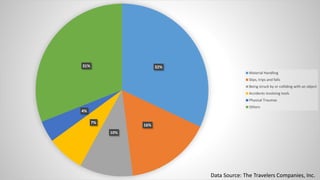

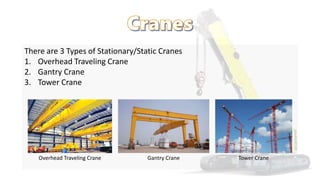

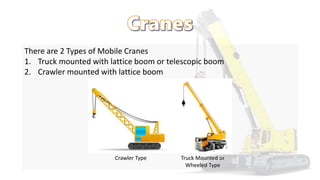

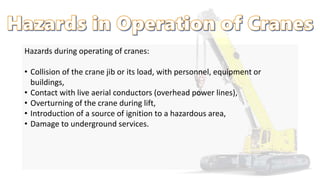

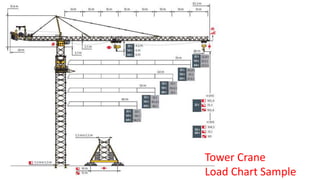

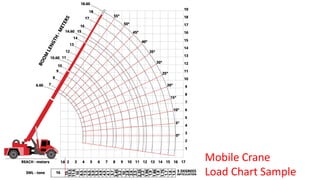

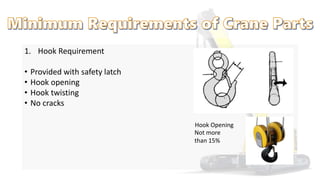

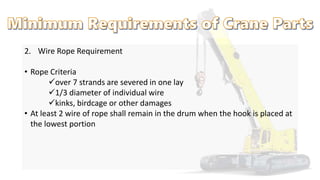

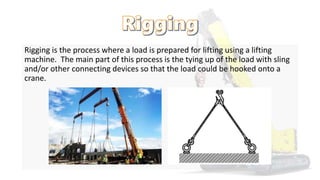

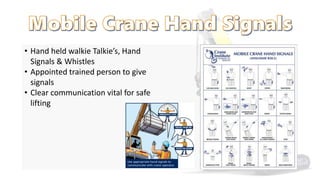

This document provides information on construction heavy equipment safety. It discusses the types of heavy equipment used on construction sites and the hazards they pose. It emphasizes the responsibilities of equipment operators to safely operate machinery and look out for other workers. Specific guidelines are provided for crane safety, including crane types, load charts, inspection criteria, safe operating procedures, and erecting/dismantling precautions. Personnel involved in heavy equipment safety like operators, spotters, and supervisors are identified.