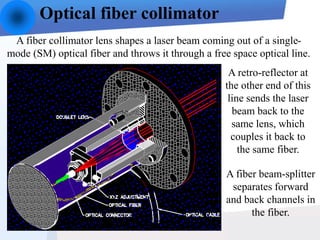

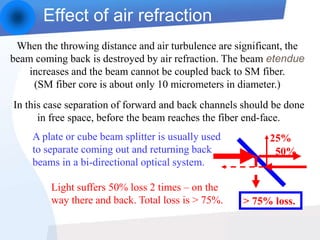

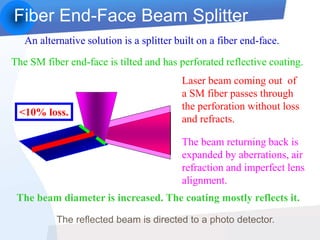

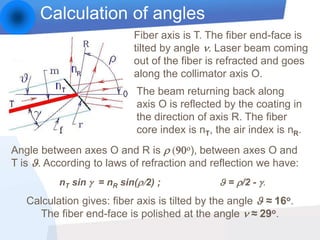

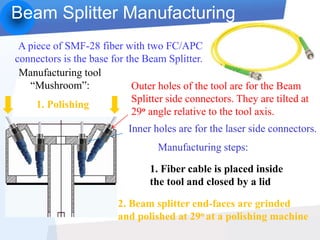

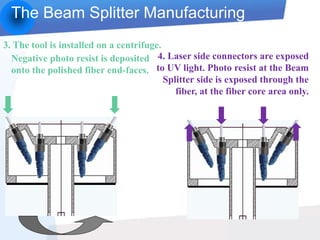

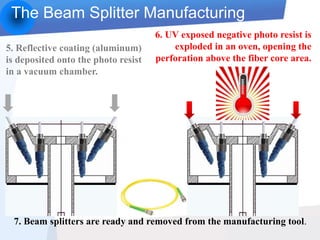

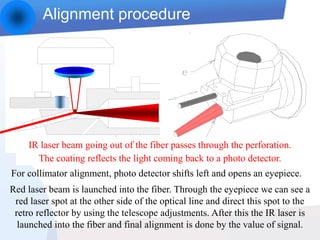

This document describes the development of a fiber end-face beam splitter that separates forward and backward channels in an optical fiber. It was developed as an alternative to free space beam splitters, which suffer from high losses of over 75%. The fiber end-face beam splitter is built by tilting and polishing the fiber end-face, then depositing a perforated reflective coating. This allows the forward beam to pass through with low loss while reflecting the expanded backward beam to a detector with under 10% loss. The document outlines the concept, manufacturing process using a customized tool, and alignment procedure for implementing this beam splitter to reduce losses in bi-directional fiber optic systems.