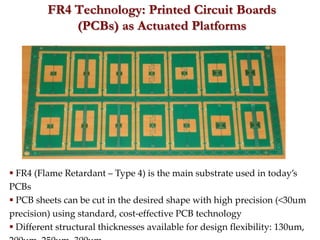

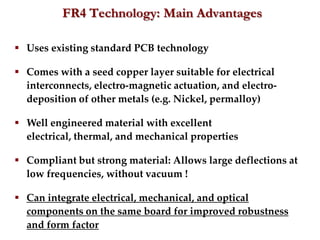

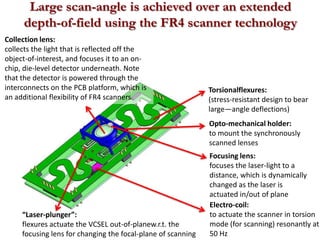

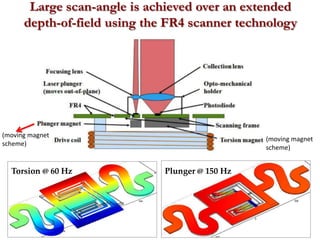

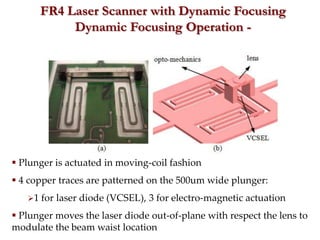

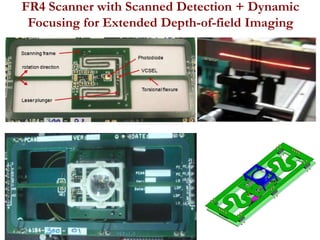

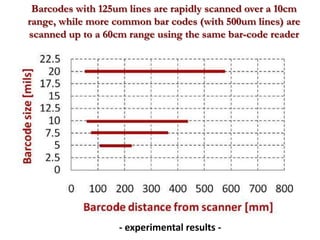

The document discusses Koç University's research on optical micro-mechatronic systems utilizing FR4 technology in printed circuit boards (PCBs) for electromagnetic actuation. It highlights the advantages of FR4, such as precision in design and the integration of various components, while detailing the operation and dynamic focusing capabilities of a laser scanner. Experimental results show the system's efficacy in scanning barcodes over varying ranges.