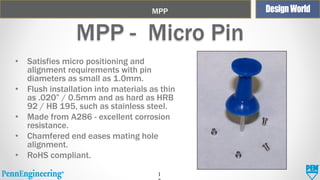

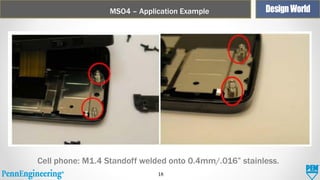

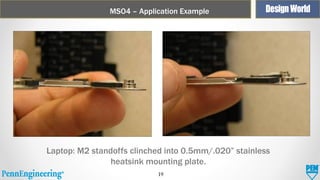

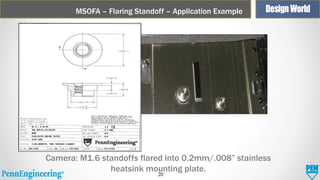

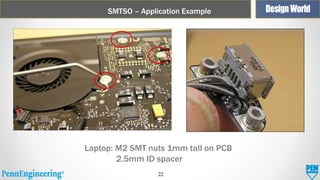

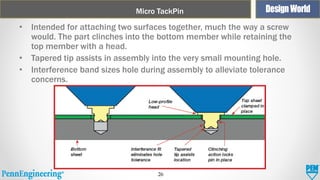

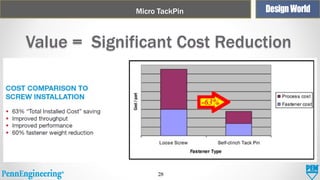

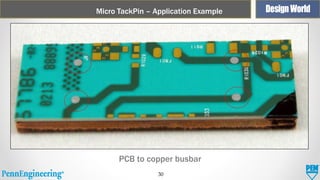

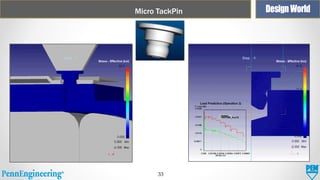

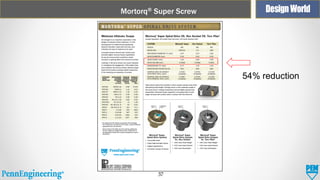

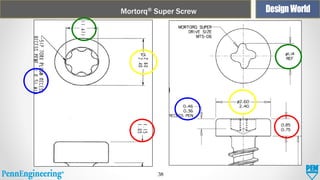

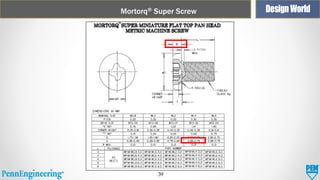

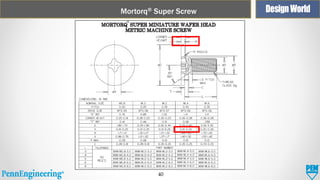

The document discusses a webinar presented by Penn Engineering on solving assembly challenges in reduced footprint applications using their micropem fastener technology. It highlights the company's history, fastener installation methods, micro fasteners overview, and the benefits of micro fasteners compared to traditional screws. Additionally, the presentation covers specific product examples and their applications in various industries.