This document contains solutions to problems involving the instability strain and necking behavior of materials under tension.

1) For a material loaded in tension where stress is related to strain by σ=Kεn, the instability strain occurs when n equals strain. The document also finds expressions for instability strain as a function of n for two different stress-strain relationships.

2) Other problems determine instability strain and pressure for thin-walled tubes undergoing internal pressurization. Expressions are derived for instability strain in terms of the stress exponent n.

3) The final problems consider the effect of non-uniform thickness on necking behavior and determine conditions required to limit thickness variations during necking.

![Chapter 4

4-3 Determine the instability strain in terms of n for a material loaded in tension

while subjected to a hydrostatic pressure P. Assume σ=Kεn

.

Solution: Hydrostatic stress has no effect on yielding so ε = n.

4-4 A thin-wall tube with closed ends is pressurized internally. Assume that

σ=150ε0.25

(MPa).

a) At what value of effective strain will instability occur with respect to pressure.

b)Find the pressure at instability if the tube had an initial diameter of 10 mm, and a 4-

1 If σ=Kεn

, the onset of tensile instability occurs when n = εu. Determine the

instability strain as a function of n if

a) σ=A(B+ε)n

b) σ=Aen

where e is the engineering strain.

Solution: a) At instability, σ = dσ/dε; A(B+ε)n

= nAB(B+ε)n-1

; ε = n(1+B)

b) σ=Aen

, dσ/dε = σ, but (dσ/dε) = (dσ/de)(dε/de). Since e =

ln(1+ε), (dε/de) = 1/(1+ε) and dσ/de = σ(dε/de).

dσ/de = nAen

. nAen-I

= Aen

(1+e), e/(1+e) = n, e = n/(1-n)

4-2 Consider a balloon made of a material that shows linear elastic behavior to

fracture and has a Poisson’s ratio of ½. If the initial diameter is do, find the diameter,

d, at the highest pressure.

Solution: P = 4σt/d; dP = 0 = 4[(σ/d)dt + (t/d)dσ – (tσ/d2

)dd];

dσ/σ = -dr/r – dt = (3/2)dε; dσ/dε = (3/2)σ; Substituting dσ/dε = E,

E = (3/2)εE; ε = 2/3. ln(d/do) = ε/2 = 1/3, so d = doexp(1/3) = 1.40do

b) wall thickness of 0.5 mm.

Solution: a) P = (2t/d)σ = (2to/do){[exp(-ε)]/[exp(ε)]}k(√4/3)n

εn

= (2to/do)k(√4/3)n

)

{[exp(-2ε)]εn

.

dP = 0 = (2to/do)k(√(4/3)n

)[nexp(-2ε)εn-1

+2εn

exp(-2ε)], ε = n/2

b) P = (2to/do)k(√4/3)n

){[exp(-2ε)]εn

=

(40)(150)(4/3)0.25/2

[0.25exp(-0.5)(0.25)0.125

+ 2(0.125).25

exp(-.25)] = 49 MPa

4-5 Figure 4.10 shows an aluminum tube fitted over a steel rod. The steel may be

considered rigid and the friction between the aluminum and the steel may be

neglected. If σ=160ε0.25

(MPa)for the tube and it is loaded as indicated, Calculate

the force, F, at instability.

10 cm

1 mm

steel

aluminum

F

Figure 4.10 Sketch for Problem 4-5.

12](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-1-2048.jpg)

![Solution: This is a plane-strain situation. σ = F/(πdt), Substituting t = toexp(-ε) and d

= do, and σ = √(3/4)σ , F = (3/4)n/2

εn

/[πdotoexp(-ε)] = [(3/4)n/2

/(πdoto)][εn

exp(ε)].

dF = 0; εn

exp(ε) + nεn

exp(ε) = 0; ε = n.

F = {(3/4)0.125

/[π(0.01)(0.001)]}(0.125)0.25

exp(0.125) = 20.7 kN

4.6 A thin-wall tube with closed ends is subjected to an ever-increasing internal

pressure. Find the dimensions r and t in terms of the original dimensions ro and to at

maximum pressure. Assume σ=500ε0.20

MPa..

Solution: This is a plane-strain situation, P = 2tσ/d; Substituting σ = √(3/4)σ =

500(4/3)0.20

ε0.20

, t = toexp(-ε) and d = doexp(ε),

P = 500(4/3)0.20

ε0.20

(to/do)exp(-2ε) = [500(4/3)0.20

(to/do][ε0.20

exp(-2ε)]

dP = 0 = [500(4/3)0.20

(to/do][0.2ε-0.80

exp(-2ε) -2ε0.20

exp(-2ε)]; ε= 0.2/2 = 0.10

P = [500(4/3)0.20

(to/do][(0.10)0.20

exp(-0.2)] =

4.7 Consider the internal pressurization of a thin-wall sphere by an ideal gas for

which PV = constant. One may envision an instability condition for which the

decrease of pressure with volume, (-dP/dV)gas, due to gas expansion is less than the

rate of decrease in pressure that the sphere can withstand, (-dP/dV)sph. For such a

condition, catastrophic expansion would occur. If σ=Kεn

, find ε as a function of n.

Solution: Assume a fixed amount of gas and neglect any temperature

changes. PV = constant, so d(PV) = 0 = PdV + vdP or dP = -PdV/V.

V = (4/3)πr3

, so dV = 4πr2

dr and dV/V = 3dr/r = 3dεr. Now, dεr =

dεθ = -dεr/2, so

dε = [(2/3)(dεr

2

+ dεθ

2

+ dεt

2

)]1/2

= 2dεr or dV/V = (3/2) dε,

then dP = -P(3/2) dε (1)

For the sphere, where σ = Kε n

and P = 2σrt/r and σr = σθ, σt = 0,

dP = (2σr/r)dt + (2t/r)dσr - (2stt/r)(dt/t + dσr/σr - dr/r) (2)

Here σ = σr = Kε n

, so dσ /σ = n dε/ε ,

dεr = dr/r = dεθ , det = dt/t =-2dεr = -2dεθ (3)

Using (3) in (1)

dP = (2σrt/r)[ddεt + n dε/ε -dεr], but dε = 2dεr and dε = -dεt

so dP = P[-dε + ndε /ε - dε /2] = P(n/ε - 3/2)dε (4)

Equating (1) and (4), -P(3/2)dε = P(n/ε - 3/2)dε or

n/ε = 0 so ε = ∞ and instability is not predicted.

4.8 For rubber stretched under biaxial tension σx = σy = σ, the stress is given by σ

= NkT(λ2 -1/λ4) where λ is the stretch ratio, Lx/Lxo = Ly/Lyo. Consider what this

equation predicts about how the pressure in a spherical rubber balloon varies during

the inflation. For to = ro , plot P vs. λ and determine the strain, λ, at which the

pressure is a maximum

12](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-2-2048.jpg)

![Solution: Plotting

.2

.4

.6

1 1.2 1.4 1.6 1.8 2

0.6

0.4

0.2

0

lambda

P/(2to/ro)

P = (2t/r) = (2to/ro)(1/λ -1/λ7

) dP/dλ = (2to/ro)(-λ-2

+7λ-8

)= 0, λ-2

=7λ-8

.

λ6

= 7, λ = 71/6

=1.38

4.9 For a material that has a stress-strain relationship of the form, σ=A−Bexp(−Cε)

where A, B and C are constants, find the true strain at the onset of necking and

express the tensile strength, Su in terms of the constants.

Solution: dσ/dε = σ; BCexp(-Cε) = A-Bexp(-Cε); A = exp(-Cε)B(C+1);

exp(-Cε)= A/[B)C+1)]; ε = -ln{A/[B(C+1)]}/C

Su - = σmaxexp(ε) = A-{A/[B(C+1)]}C+1

????

4-10 A tensile bar was machined with a stepped gage section. The two diameters

were 2.0 and 1.9 cm. After some stretching the diameters were found to be 1.893 and

1.698 cm. Find n in the expression σ=Kεn

, find ε as a function of n.

Solution:

f = (0.0297/0.0303) = 0.9802, εb = 0.2, εa = n

Substituting into fεa

n

exp(-εa) = εb

n

exp(-εb)

0.9802n

nexp(-n) = 0.2n

exp(-0.2); 0.9802n

nexp(-n/.2) - 0819 = 0

by trial and error, n = 0.301

4-11 In a rolled sheet, it is not uncommon to find variations of thickness of ±1%

from one place to another. Consider a sheet nominally 0.8 mm thick with a ±1%

variation of thickness. (Some places are 0.808 mm and others are 0.792 mm thick.)

How high would n have to be to insure that in a tensile specimen every point was

strained to at least ε = 0.20 before the thinner section necked?

Solution:

Let the region with the smaller diameter be designated a and the region with the

larger diameter be b. Using a force balance, fεa

n

exp(-εa) = fεb

n

exp(-εb) ; εa =

ln(1.9/1.698) = 0.2248,

εb = 2ln(2/1.893) = 0.1100, f = (1.9/2)2 = 0.9025.

0.9025(0.2248)ln(0.799) = (0.110)ln(0.896)

(.2248/.110)n = 1.243; n = ln1.243/ln2.0455 = 0.304

12](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-3-2048.jpg)

![4-12 A material undergoes linear strain hardening so that σ = Y + 1.35Yε, is

stretched in tension.

a) At what strain will necking begin?

b) A stepped tensile specimen was made from this material with the diameter of

region A being 0.990 times the diameter of region B. What would be the strain in

region B when region a reached a strain of 0.20?

Solution: a) dσ/dε = 1.35Y = σ = Y(1+1.35ε); ε = 0.35/1.35 = 0.26

b) F = σAAA = σBAB = Y(1 + 1.35εA)AAoexp(-εA) = Y(1 + 1.35x0.20)ABo exp(-0.20)

(1 + 1.35εA)exp(-εA) = (1 + 1.35x0.20)(1/0.99)exp(-0.20) = 1.050

Region A will not have yielded

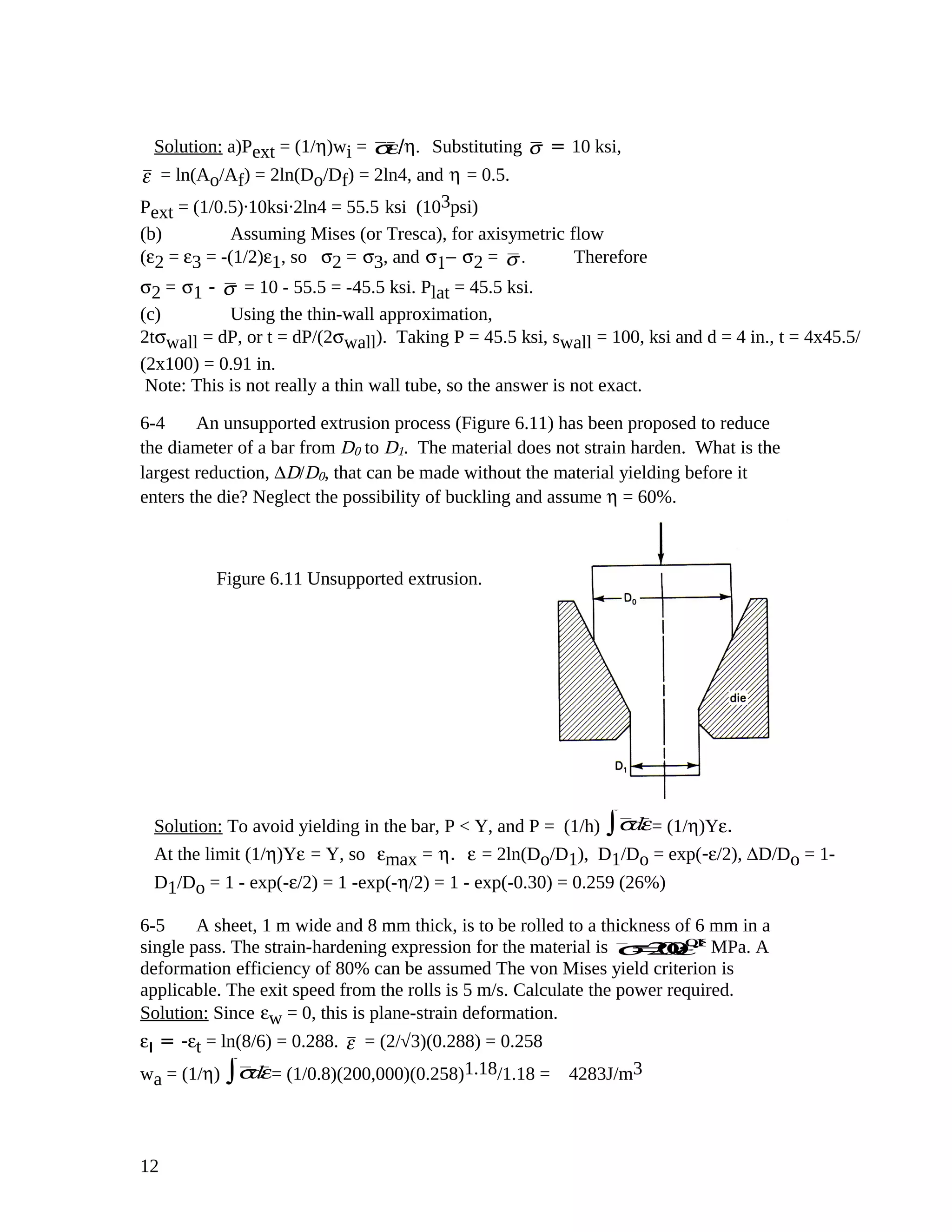

Chapter 5

5.1 Low-carbon steel is being replaced by HSLA steels in automobiles to save

weight because the higher strengths of HSLA steels permit use of thinner gauges. In

laboratory tests at a strain rate of about 10-3

s-1

, one grade of HSLA steel has a yield

strength of 420 MPa with a0 strain-rate exponent of m = 0.005 while for a low-carbon

steel, Y = 240 MPa and m = 0.015. Calculate the percent weight saving possible for

the same panel strength assuming

a. a strain rate of 10-3

s-1

,

b. crash conditions with a strain rate of 10+4

s-

.

Solution: Assume the thickness are chosen so both materials can sustain the same force at

yielding. Then t2Y2 = t1Y1, or t2/t1 = Y1/Y2. Since both steels have the same density,

W2/W1 = t2/t1 = Y1/Y2 = 35/60 = 0.583.

% weight reduction = (W1-W2)/W1 = 1- W2/W1 = 1 - 0.583 = 41.7%

b) Now W2/W1 = [Y2(104/10-3).03]/[Y1(104/10-3).01] = (Y1/Y2)(107).03-.01 =

1.380(Y1/Y2) = 1.380.0.583 = 0.805

% weight reduction = 1 - 0.805 = 19.5%

c.

5.2 The thickness of a sheet varies from 8.00 mm to 8.10 mm depending on

location so tensile specimens cut from a sheet have different thicknesses.

a. For a material with n = 0.15 and m = 0, what will be the strain in the

thicker region when the thinner region necks?

b. If n = 0 and m = 0.05, find the strain in the thicker region then the strain in

the thinner region is 0.5 and ∞.

Solution: a) Substituting n = 0.15, f = 8/.810 = 0.9877 and εa = n = 0.15 into fεa

nexp(-εa) =

εb

nexp(-εb), 0.9877(0.15)0.15

exp(-0.15) = εb

0.15exp(-eβ); εb

0.15exp(-εb) = 0.6395

Solving by trial and error, εb = 0.096 [This agrees with fig. 4-8]

b) Substituting m = 0.15 and εa = 0.50 into eq. (5-11)

12](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-4-2048.jpg)

![exp(-εb/m)-1 = f1/m [exp(-εa/m) -1], and solving, εb* = 0.327.

For εa = ∞, eb* = -mln(1-f1/m) = -0.15ln(1- 0.98761/.15) = 0.379

5.3 a) Find the % elongation in the diagonal ligaments in Figure 5.6, assuming

that the ligaments make an angle of 75° with the horizontal.

b) Assuming that f = 0.98 and n = 0, what value of m is required for the variation of

thickness along the ligaments be held to 20%? (The thickness of the thinnest region

is 0.80 times the thickness of the thickest region.)

Solution: a) L/Lo = 1/cos75 = 3.864. elongation = L/Lo - 1 = 2.864 = 286 %

b) The average strain = 3.864 = 1.352. First assume that this is the largest strain, so εa

= 1.352. tb/ta = 1.20 = [tboexp(-εb)]/[taoexp(-εa)] = (1/f)exp(-εb)/exp(-εa)

exp(-εb) = 1.2(0.98)exp(-1.352) = 0.3043, eb = 1.897

Now substituting into exp(-εa/m) - 1 = f1/m[exp(-εb/m) - 1] exp(-1.352/m) - 1 =

(0.98)1/m[exp(-1.897/m) - 1]. Solving by trial and error, m = 0.577

The other extreme assumption is that eb = 1.352. Then following the same procedure,

exp(-1.897/m) - 1 = (0.98)1/m[exp(- 1.352/m) - 1]. Solving by trial and error, m = 0.66. The

correct answer must be between 0.577 and 0.66. A reasonable estimate is m = 0.62

5.4 Find the value of m’ in equation 5.10 that best fits the data in Figure 5.28.

Solution: m' = dσ/dln(ε¥), dσ = m' dln(ε¥) = m'(dε¥/ε¥)

also σ = C`εm so dσ = mC ε¥m-1d`ε.

Equating m'(dε¥/ε¥) = mC ε¥m-1d Ýε , m' = mC ε¥m = mσ

Using points from Fig 5-28, m = 0.05 at s = 30 ksi,

m' = 30(0.05) = 1.5 ksi

Also for m = 0.022, σ = 60 ksi so m' = 60(0.022) = 1.32 ksi

and for m = 0.012, σ = 100 ksi so m' = 100(0.012) = 1.20 ksi

These average to m' = 1.3 ksi

5.5 From the data in Figure 5.23, estimate Q in equation 5.12 and m in equation

5.1 for aluminum at 400°C.

12

Figure 5.28 Effect of

stress level on the strain-

rate sensitivity of steel.

Adapted from A. Saxena

and D. A. Chatfield, SAE

Paper 760209 (1976)](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-5-2048.jpg)

![Solution: ε¥= Aexp[-Q/(RT)] so Ýε 2/ Ýε 1 =exp[-(Q/R)(1/T2-1/T1)] and Q = Rln( Ýε 2/ Ýε 1)/

(1/T1-1/T2) = R∆ln Ýε /∆(1/T)

The slope of the 2500 psi line at 400°C is ∆ln Ýε /D(1/T) = ln100/0.22x10-3 = 20,900°C

So Q = 8.31x20,900 = 174x103 J/mole or 174 kJ/mole

b) For σ = C Ýε m, m = ln(σ2/σ1)/ln Ýε 2/ Ýε 1 ). At 400°C, σ = 4000 psi gives ε¥= 4/min. and σ

= 1500 psi gives Ýε = 0.25/min. Substituting,

m = ln(4000/1500)/ln(4/0.25 ) = 0.354

5.6 Estimate the total elongation in a tensile bar if

a. f = 0.98, m = 0.5 and n = 0

b. f = 0.75, m = 0.8 and n = 0.

Solution: a)Substituting f = 0.98 and m = 0.5 into εb* = -mln(1-f1/m),

eb* = -0.5ln(1-0.982) =1.1615, l/lo = exp(eb) = exp(1.1615) = 5.02 (502 %)

b) With f = 0.75 and m = 0.8 , εb* = -0.8ln(1-0.751/.8) = 0.958

l/lo = exp(εb) = exp(0.958) = 2.06 (206 %)

5.7 Estimate the shear strain necessary in the shear bands of Figure 5.27 necessary

to explain the formation of untempered martensite if the tensile strength level was

1.75 GPa, n = 0 and adiabatic conditions prevailed.

Solution: ∆T = ασε/(ρC) so ε = ρC∆T/ασ a. Untempered martensite can only be formed

from austenite, so austenite must have formed in the shear bands. Thus the temperature must

have risen to at least 750°C. Assuming an initial temperature of 20°C, ∆T = 730°C. Substituting

ρ = 7.87Mg/m3,

C = 0.46 kJ/kg.°C and α = 1, ε = 1.53. Assuming pure shear, γ = 2ε = 3.06.

5.8 During superplastic forming it is often necessary to maintain a constant the

strain rate.

a. Describe qualitatively how the gas pressure should be varied to form a

hemispherical dome by bulging a sheet clamped over a circular hole with gas

pressure.

b. Compare the gas pressure required to form a hemispherical dome of 5

cm diameter with the pressure for a 0.5 m diameter dome.

Solution: a) For a constant Ýε , σ must be constant (i.e. σ = C Ýε m) but σ = Pρ/(2t) (Equation. 3-

19). Although t decreases as the bulge is formed, its change is small compared with the change

of r which decreases from ∞ at the start to the radius of the dome. Therefore P must increase

gradually from 0 at the start to a maximum at the hemispherical shape, roughly in proportion to

1/r.

b) For a 20 in. dia. dome, the pressure is 1/10 that for a 2 in. dome since P is roughly

proportional to 1/ρ.

12](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-6-2048.jpg)

![5.9 During a creep experiment under constant stress, the strain rate was found to

double when the temperature was suddenly increases from 290C to 300°. What is the

apparent activation energy for creep?

b. The stress level in a tension test increased by 1.8% when the strain rate was

increased by a factor of 8. Find the value of m.

Solution: a) Since ε¥= Aexp[-Q/(RT)], Ýε 2/ Ýε 1 =exp[-(Q/R)(1/T2-1/T1)] and

Q = Rln( Ýε 2/ Ýε 1)/(1/T1-1/T2) = 8.32ln2/(1/563-1/573) =186x103 J/mole or 186 kJ/mole

b) m = ln(σ2/σ1)/ln( Ýε 2/ Ýε 1) = ln(1.018)/ln8 = 0.0086

5-10 Figure 5.29 gives data for high-temperature creep of α-zirconium. In this

range of temperatures, the strain rate is independent of strain.

a. Determine the value of m that best describes the data at 780°C

b. Determine the activation energy, Q, in the temperature range 700°C to 810°C

at about 14 MPa.

Solution: a) m = ln(σ2/σ1)/ln( Ýε 2/ Ýε 1) = ln(20/10)/ln(2.6x10-3

/3.2x10-5

) = 0.104.

b) Q = Rln( Ýε 2/ Ýε 1)/(1/T1-1/T2) = 8.ln(8x10-4

/4.5x10-5

) /(1/073-1/1093) = 212 kJ/mole

5.10 Tension tests were made in two different labs on two different materials. In

both the strain hardening exponent was found to be 0.20, but the post-uniform

elongations were quite different. Offer two plausible explanations.

Solution: One possibility is that the two materials had different values of m. Another

is that the two labs used specimens with different ratios of gauge length-to-diameter.

Chapter 6

6.1 The diameter, D0, of a round rod can be reduced to D1 either by a tensile force

of F1 or by drawing through a die with a force, Fd. as sketched in Figure 6.9.

12

Figure 5.29 Strain-rate

vs. stress for α-

zirconium at several

temperatures.](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-7-2048.jpg)

![Assuming ideal work in drawing, compare F1 and Fd (or σ1 and σd) to achieve the

same reduction.

Figure 6.9 Sketch for Problem 6-1

Solution: In drawing, the homogeneous work per volume wa = the drawing stress, σd, so σd =

σdε∫ = Kεn+1/(n+1) assuming η = 1. The tensile stress required to induce a strain ε1 is σ1 =

Kε1

n. Comparing, σd/σ1 = ε1/(n+1). The maximum uniform strain in tension is n, so the ratio

σd/σ1 < 1.

6-2 Calculate the maximum possible reduction, r, in wire drawing for a material

whose stress strain curve is approximated by σ=200ε0.18

MPa. Assume an efficiency

of 65%.

Solution: ε* = n(1+η) = 0.18(1.5) = 0.27. ε = ln[1/(1-r)], r = 1 – exp(-ε) = 23.7%

6-3 An aluminum alloy billet is being hot extruded from 20 cm diameter to 5 cm

diameter as sketched in Figure 6.10. If the flow stress at the extrusion temperature is

40 MPa. Assume η = 0.5.

a) What extrusion pressure is required?

b) Calculate the lateral pressure on the die walls.

die

die

billetPext 5 cm

20 cm

Figure 6.10 Aluminum billet being extruded.

12](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-8-2048.jpg)

![The rate of work is wa

.velocity.cross-sectional area = 4283J/m3.(5m/s)(1x0.006m2) = 128 J/s.

6-6 The strains in a material for which σ=350ε0.20

MPa are ε1 = 0.200 and

ε2 = -0.125. Calculate the work per volume assuming η = 1.

Solution: ε3 = -ε1 + ε3 = -.200 + .125 = -.075

ε = [(2/3))0.22 + 0.1252 + 0.0752)1/2 = 0.202

[Check: 0.2 < 0.202 < 1.15x0.2]

w = Kε n+1/(n+1) = 350x0.2021.2/1.2 = 678MJ/m3

6-7 You are asked to plan a wire-drawing schedule to reduce copper wire from 1

mm to 0.4 mm diameter. How many wire drawing passes would be required if to be

sure of no failures, the drawing stress never exceeds 80% of the flow stress and the

efficiency is assumed to be 60%?

Solution: The maximum strain per pass ε = = 0.6 . The total strain must be ln(1/0.4) =

1.22. Note that 1.22/0.6 = 2.033. Three passes are required (not 2).

6.8 Derive an expression for ε* at the initiation of drawing when the outlet

diameter is produced by machining.

Solution: In this case, the maximum drawing stress is .

σd(max) = Su = K(n/e)n so (n/e)n = (1/η)ε*n+1/(n+1), where e = the base of natural logarithms

ε* = [η(n+1)(n/e)n]1/(n+1)

6.9 For a material with a stress-strain relation, σ = A + Bε, find the maximum strain

per wire drawing pass if µ = 0.75.

Solution: σd = σdε∫ = ∫(A + Bε)dε = Aε + (Β/2)ε2

. The drawing limit corresponds

to

σ = σd or A + Bε = Aε + (Β/2)ε2

. (Β/2)ε2

+(Α−Β)ε - A = 0. Using the

quadratic formula, ε = {-(A-B)±√[(A-B)2

+ 4AB/2]}/B = {-(A-B)±√[(A2

+B2

]}/B

12](https://image.slidesharecdn.com/solutionmanual4-6-150303094023-conversion-gate01/75/Solution-manual-4-6-10-2048.jpg)