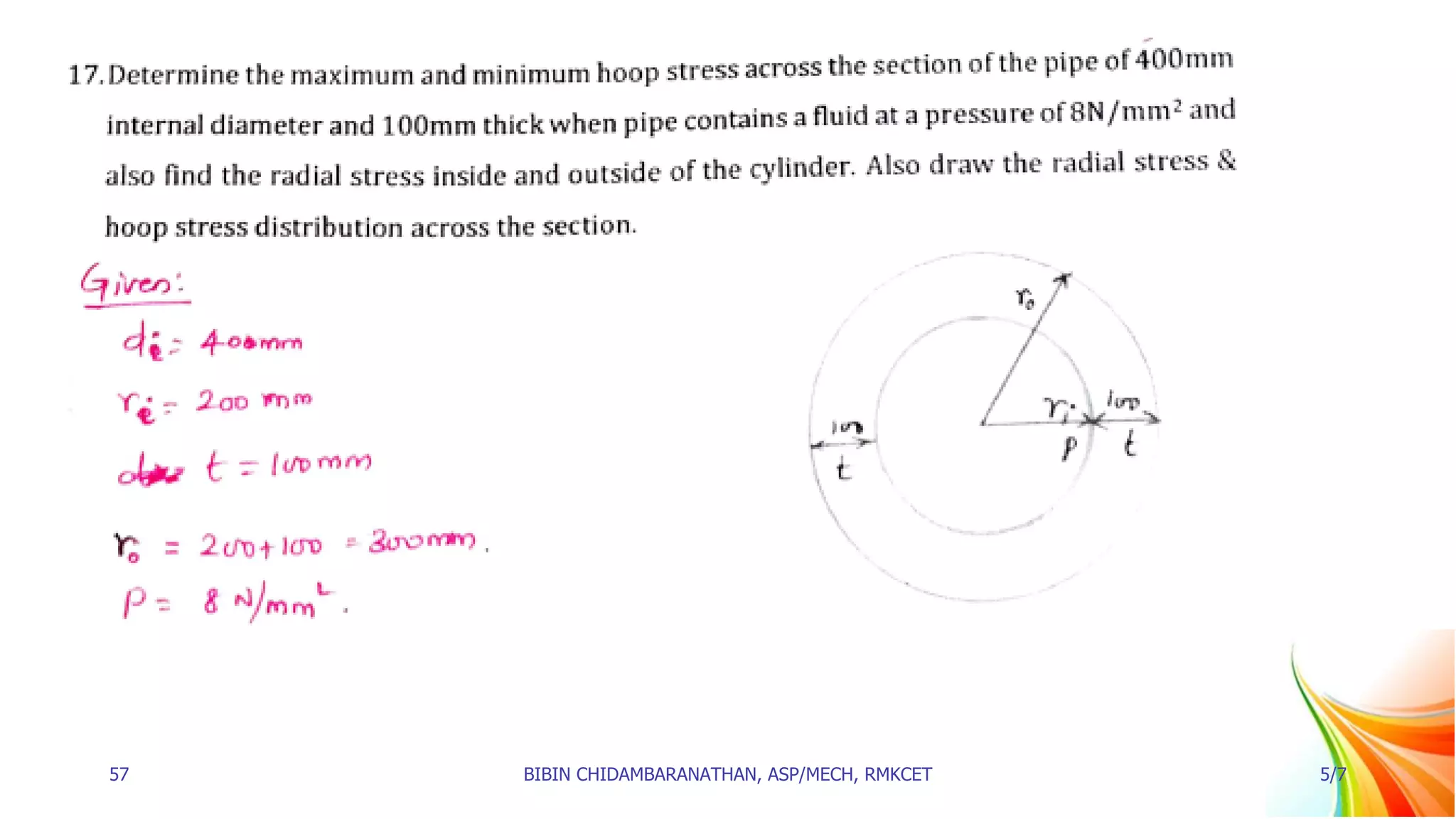

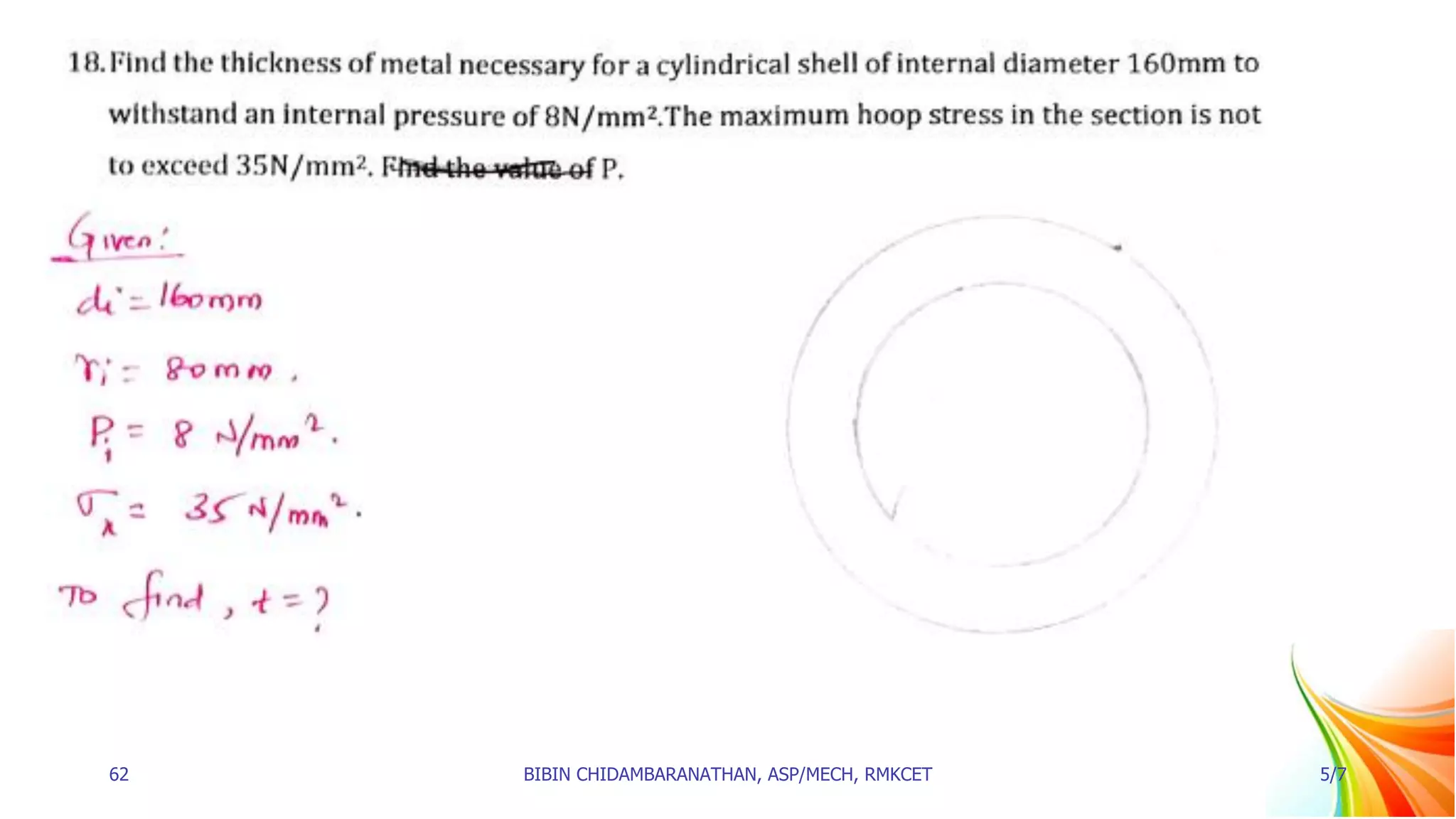

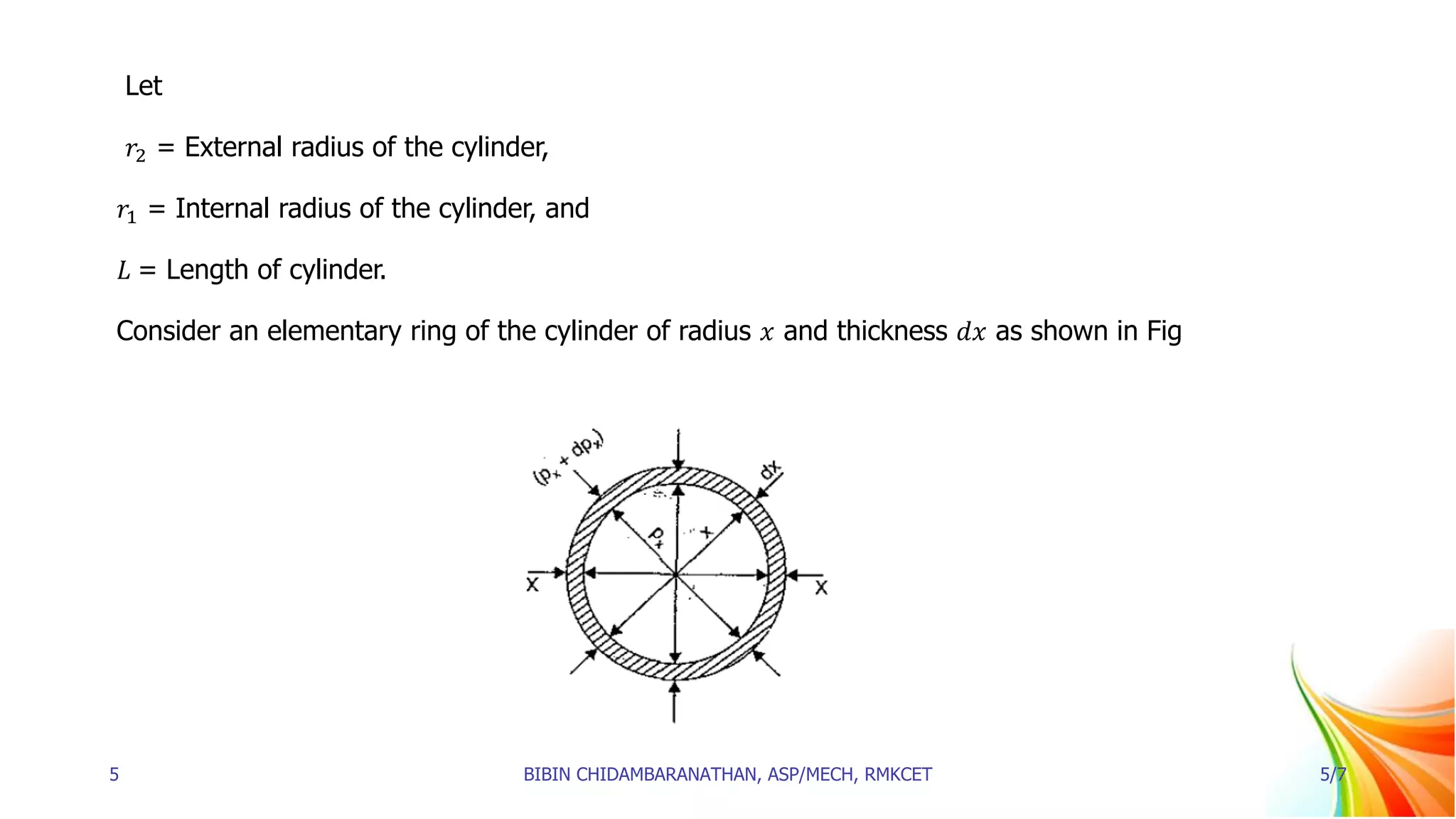

1. Thick cylinders are defined as cylinders where the ratio of thickness to internal diameter is greater than 1/20. For thick cylinders, the hoop stress varies across the thickness from a maximum at the inner circumference to a minimum at the outer circumference.

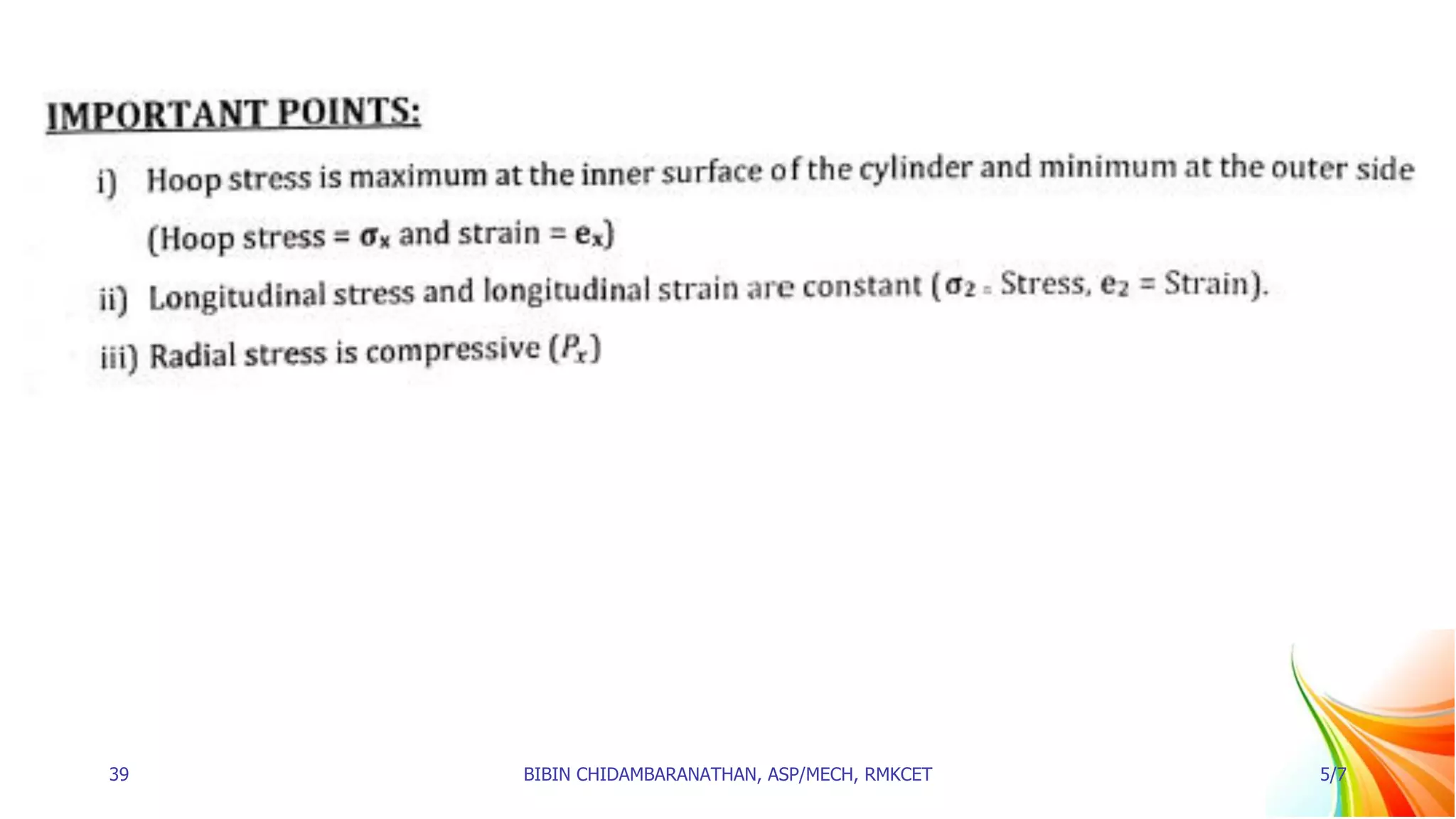

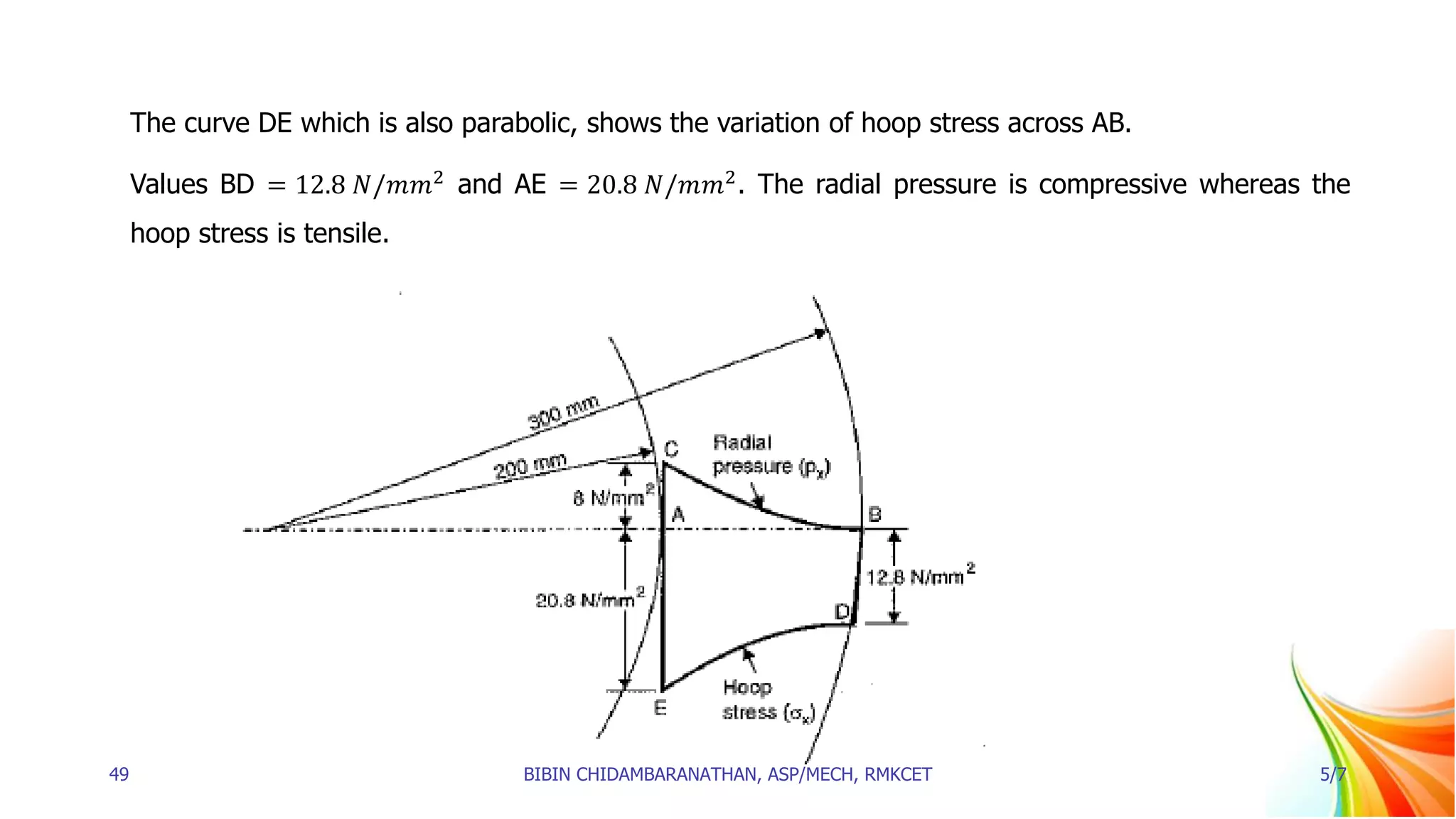

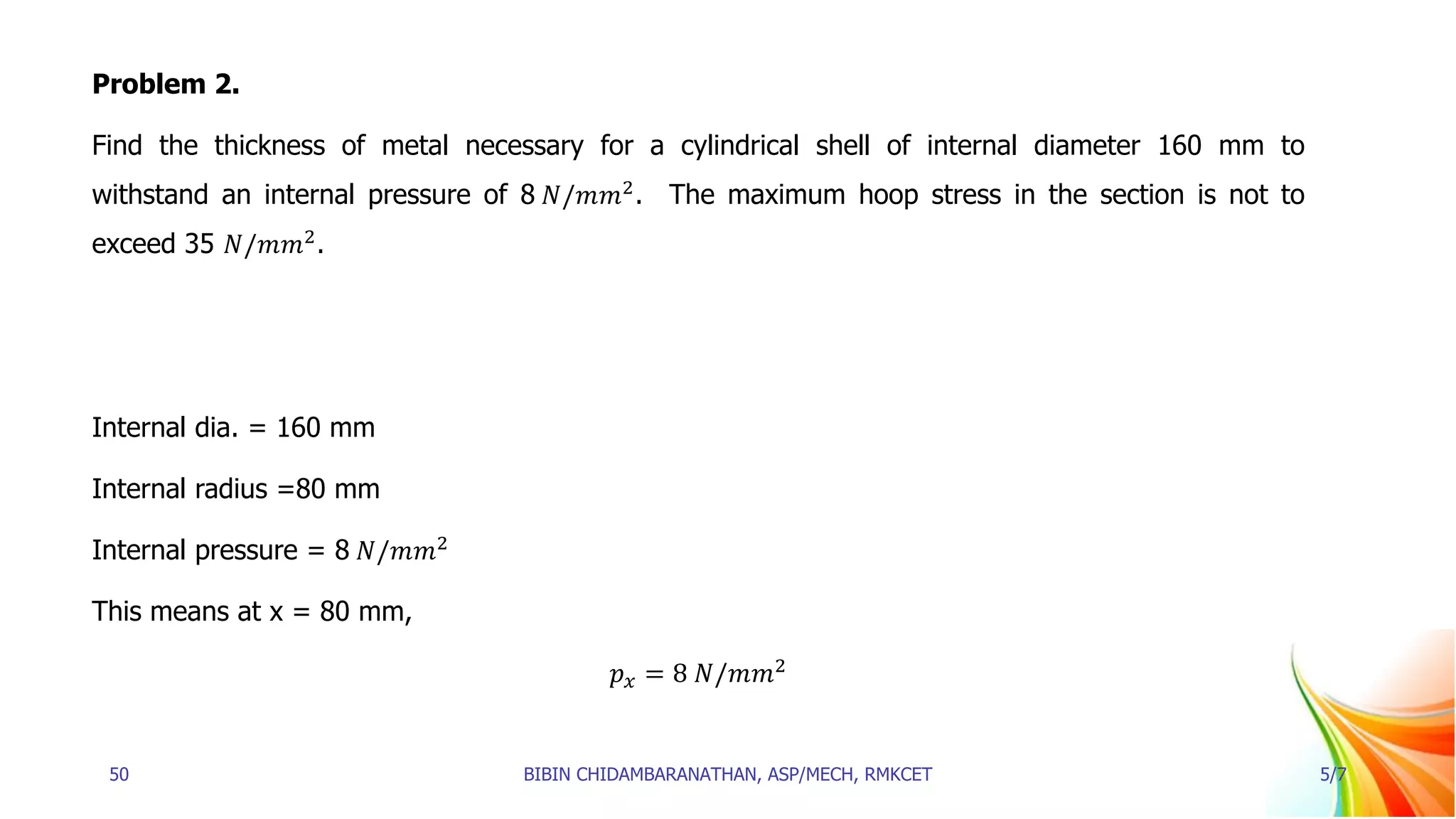

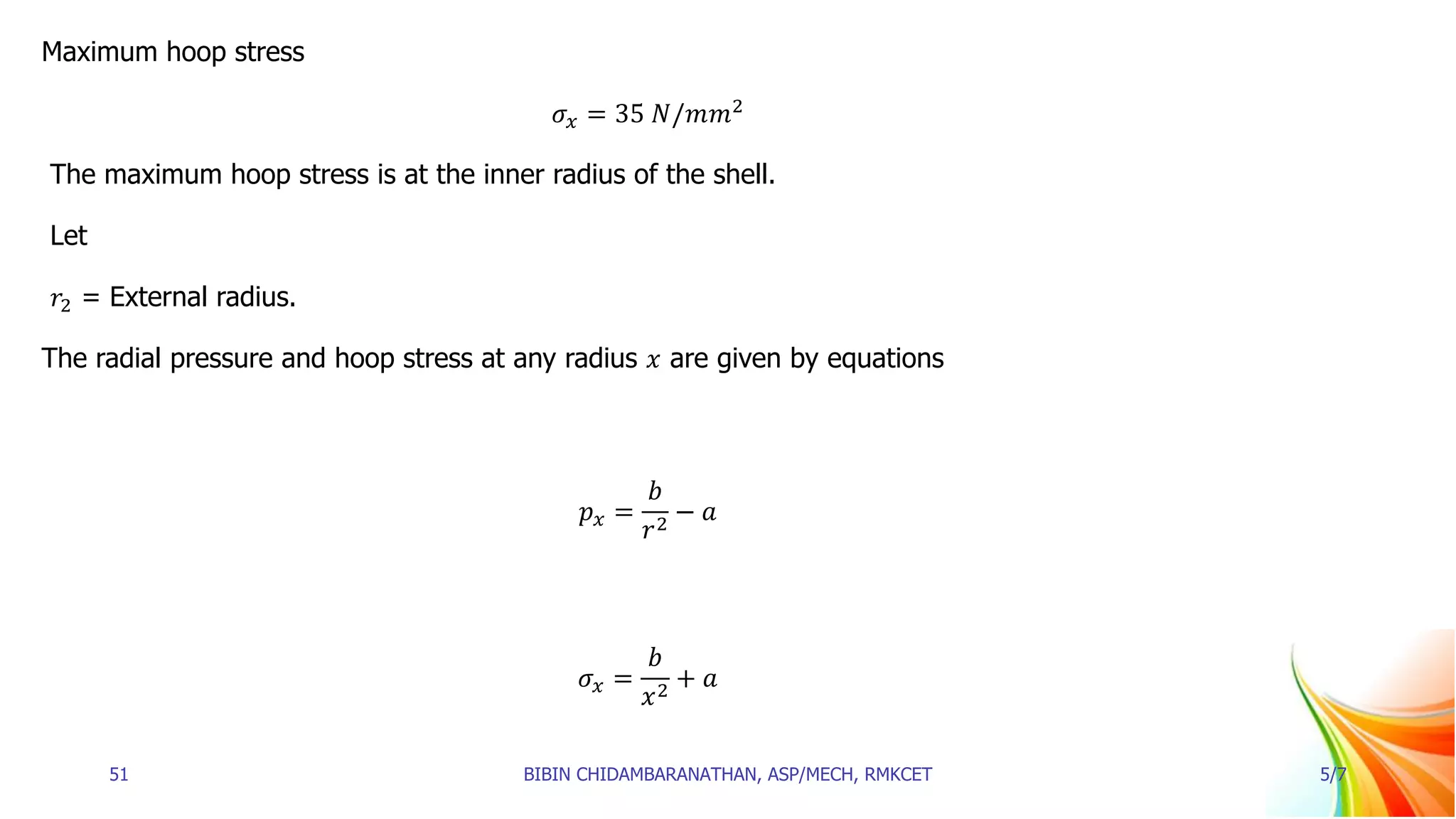

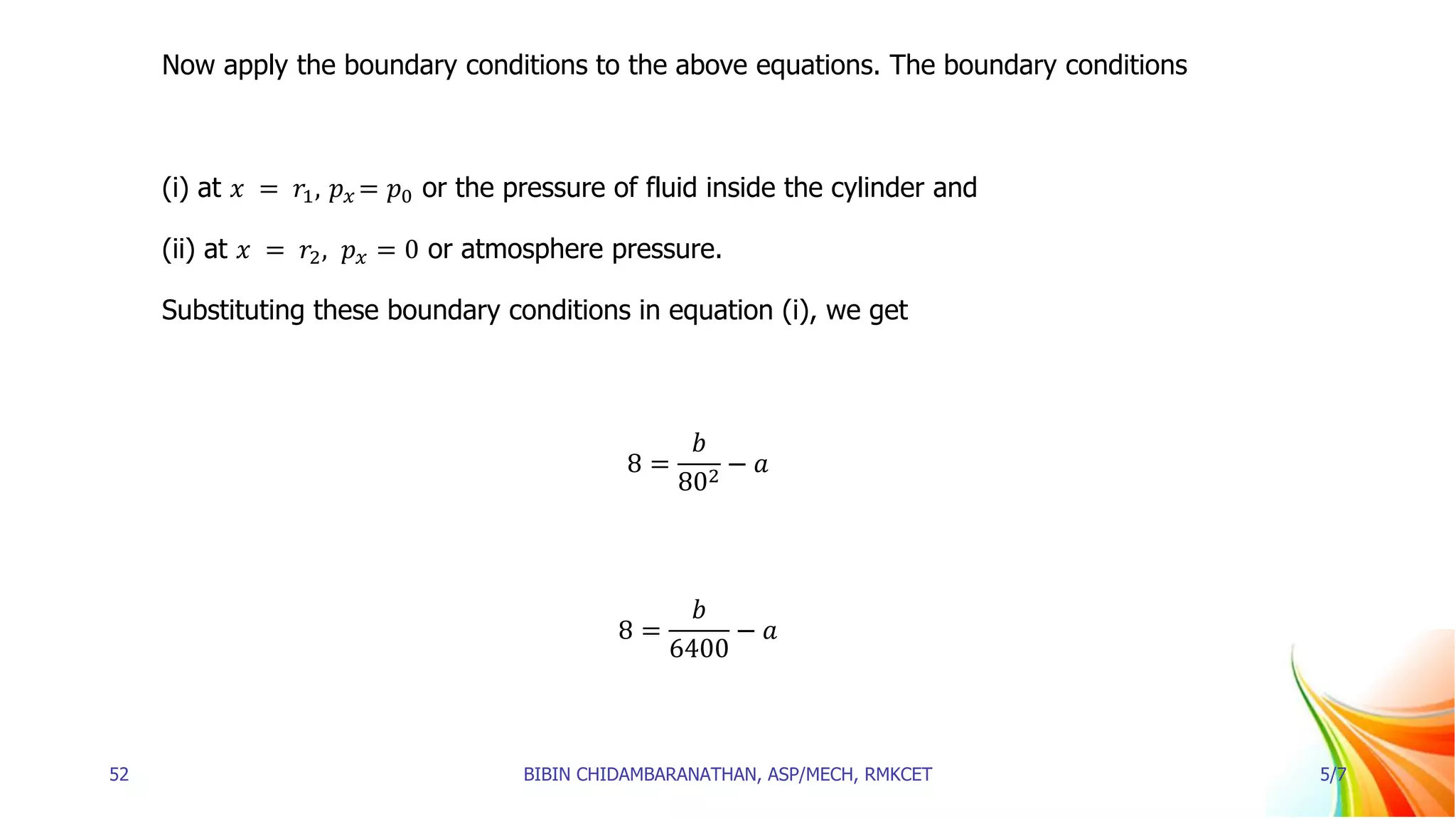

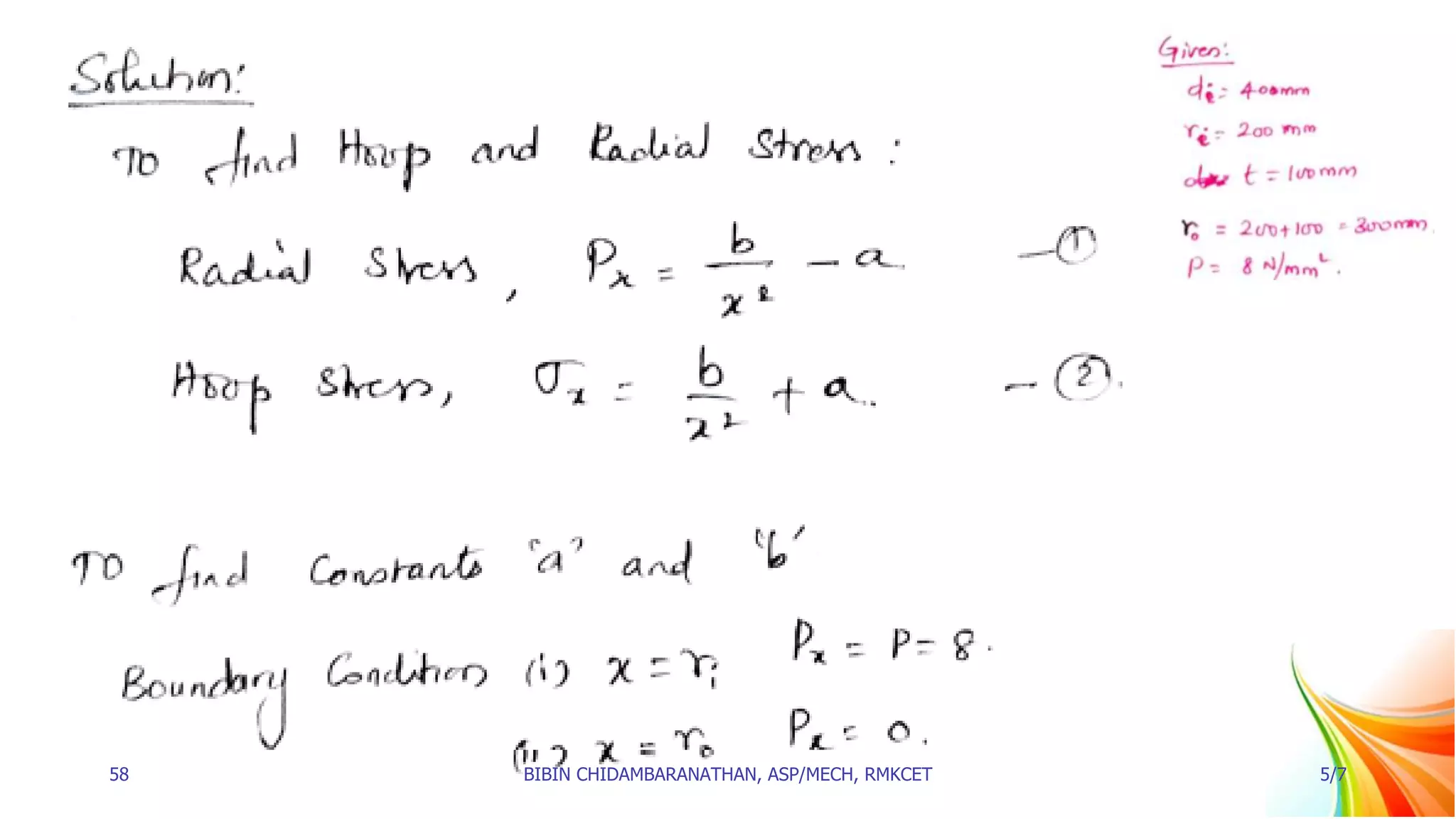

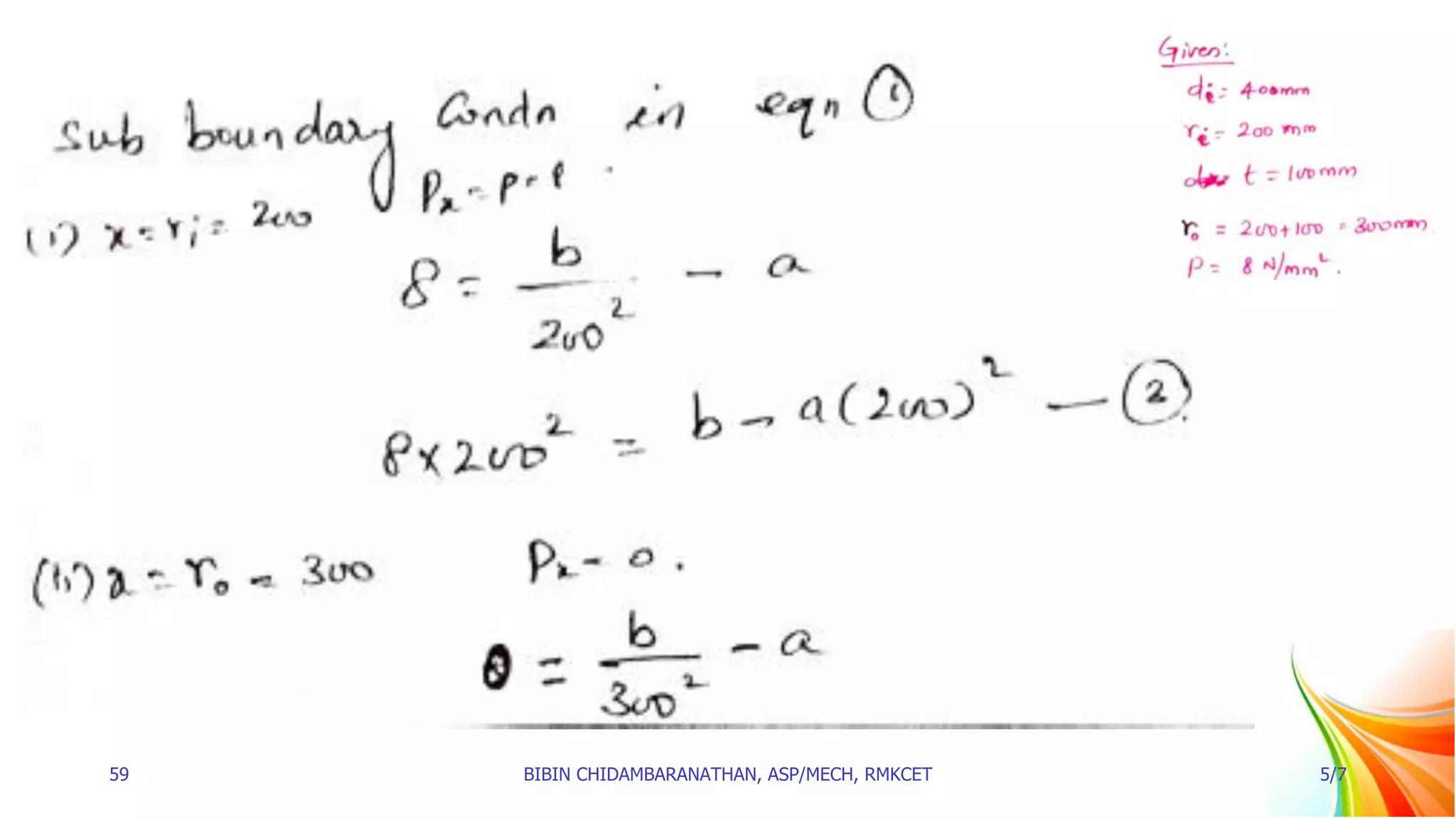

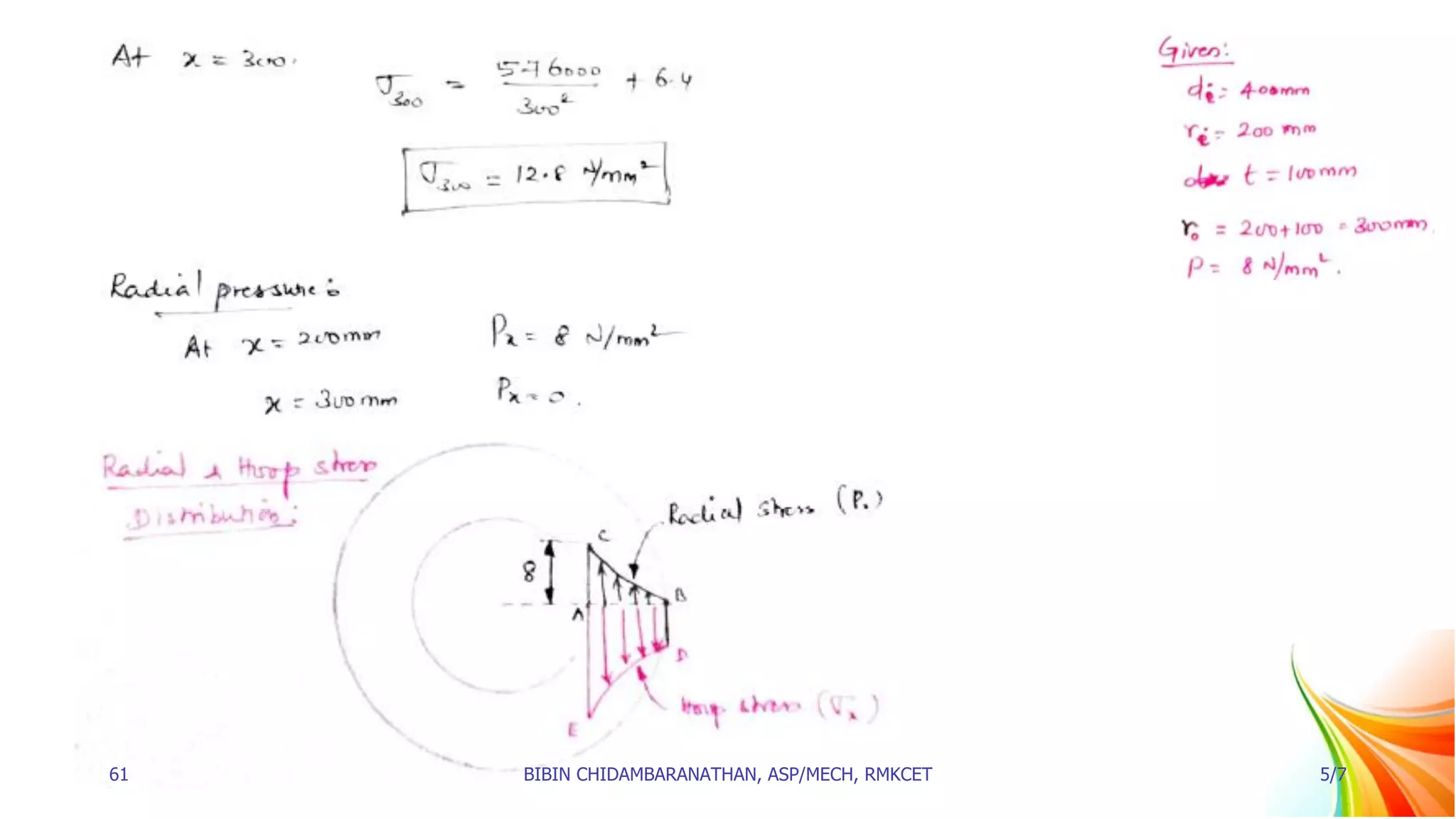

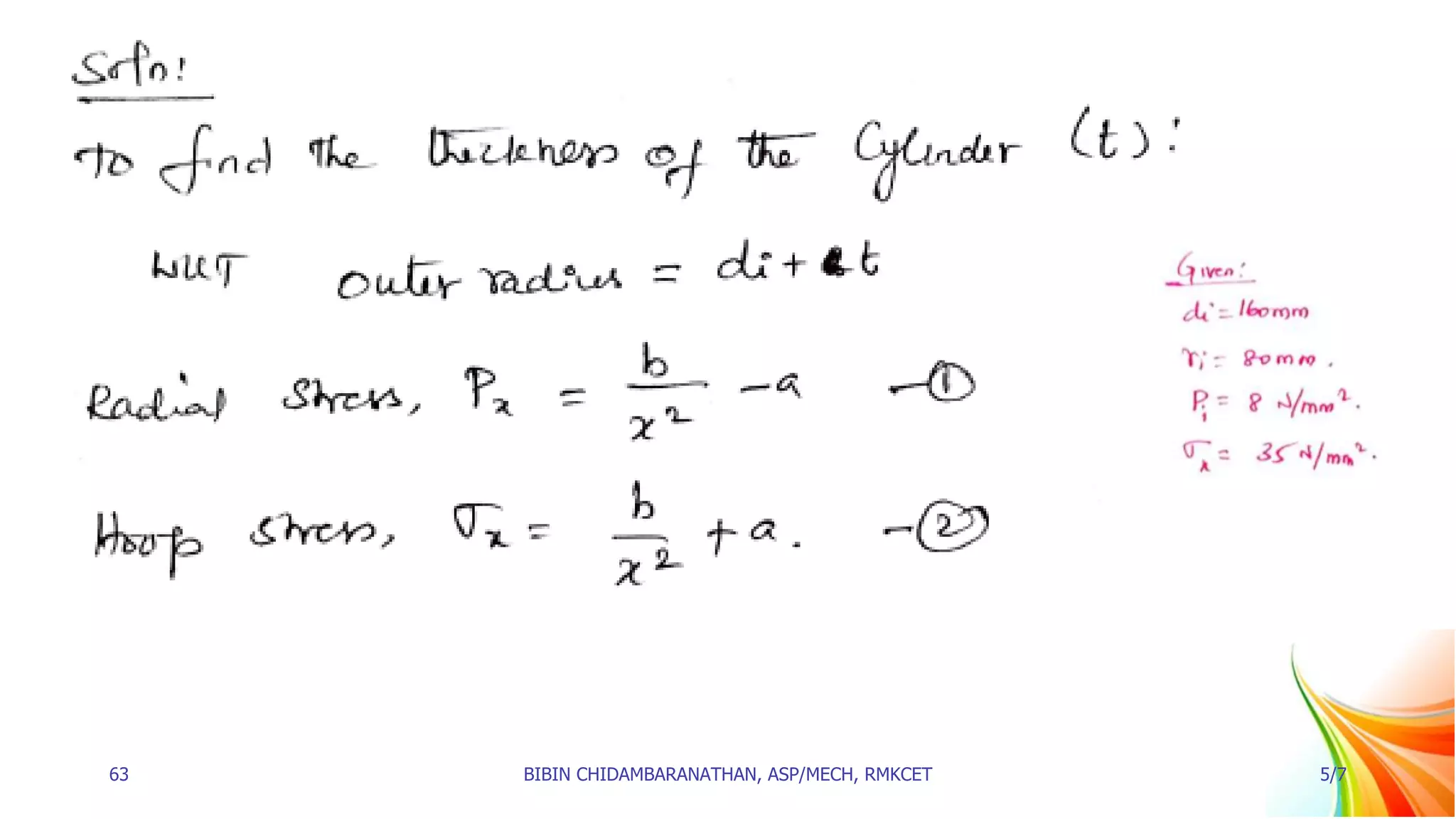

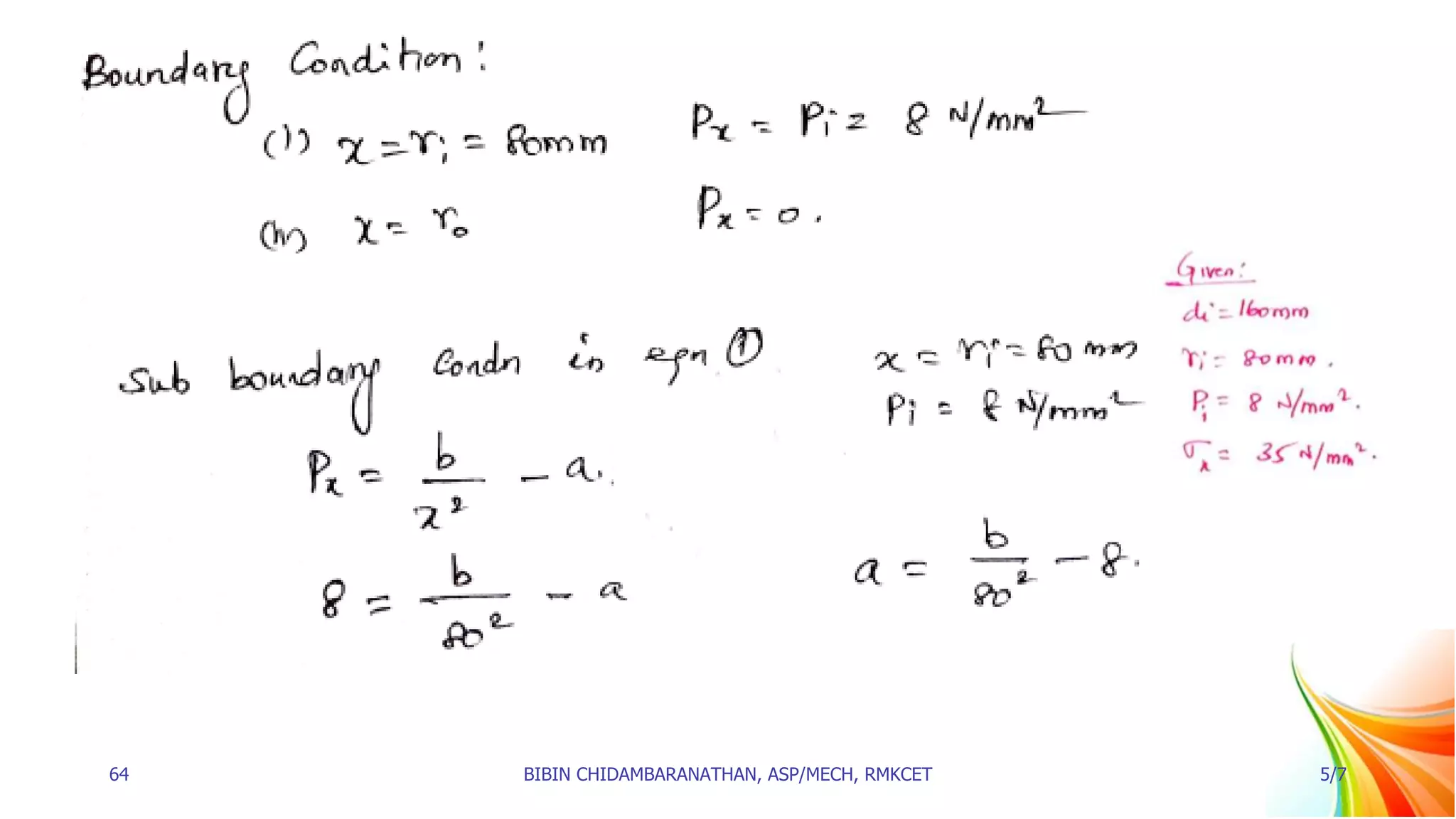

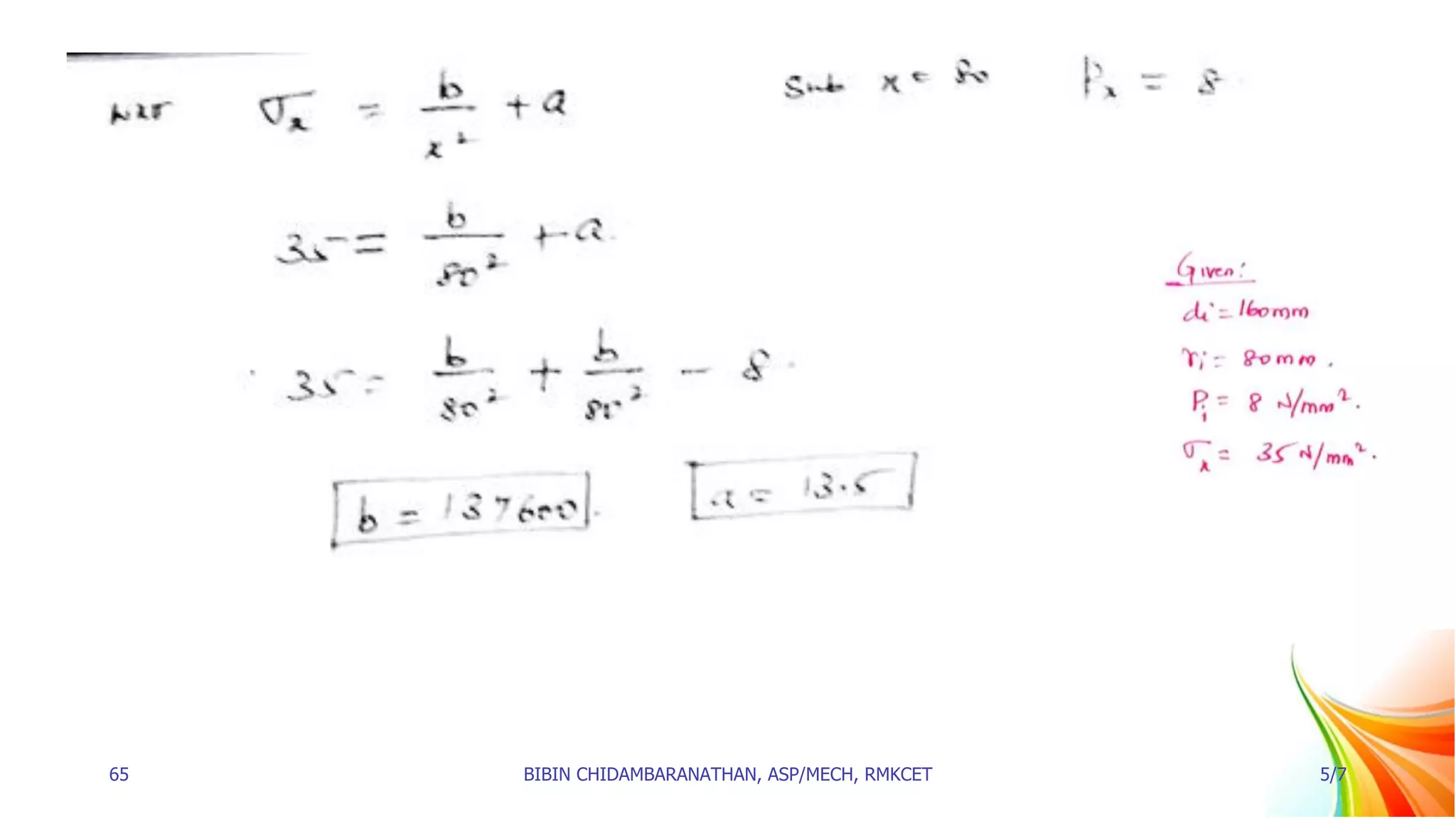

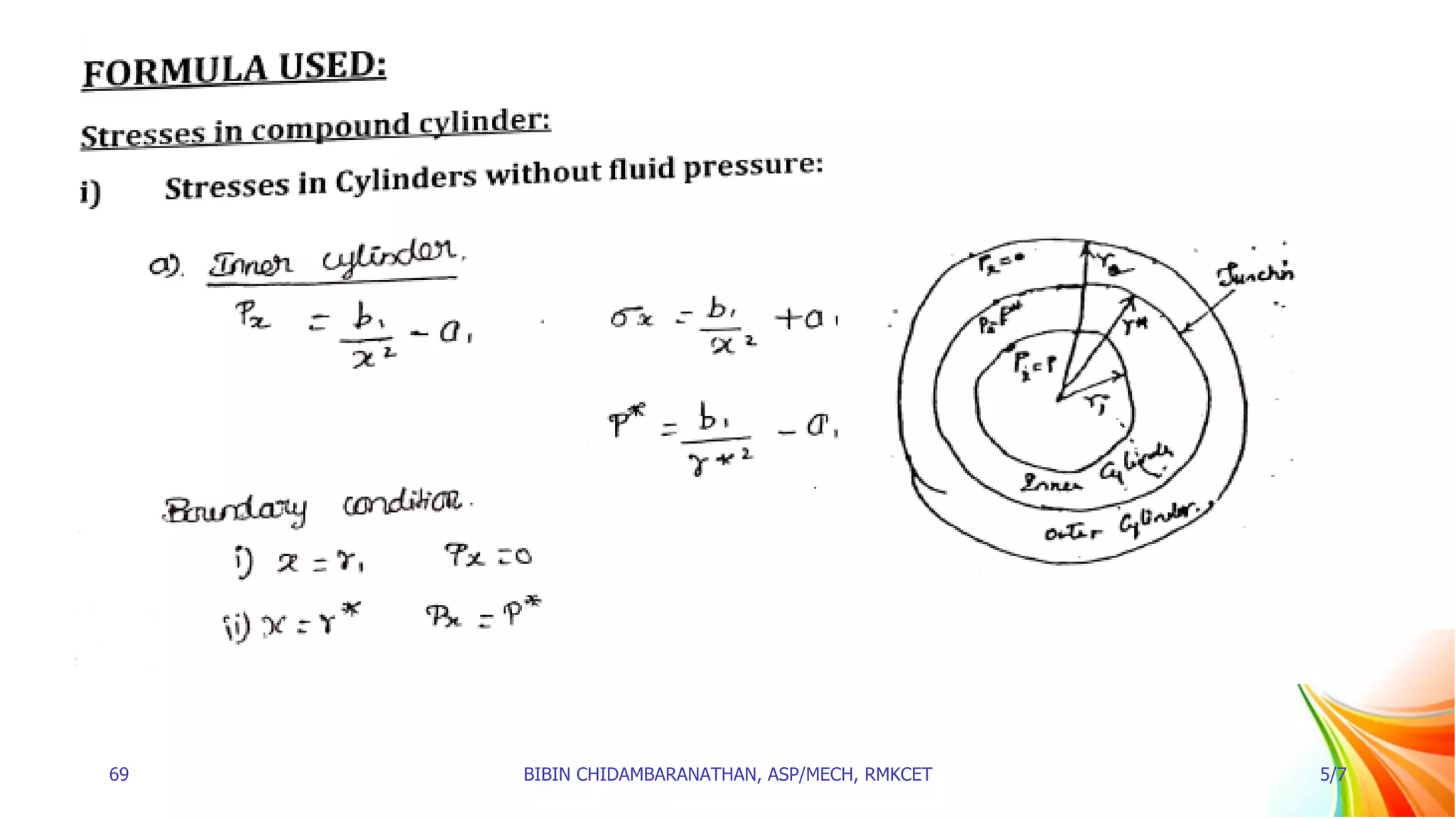

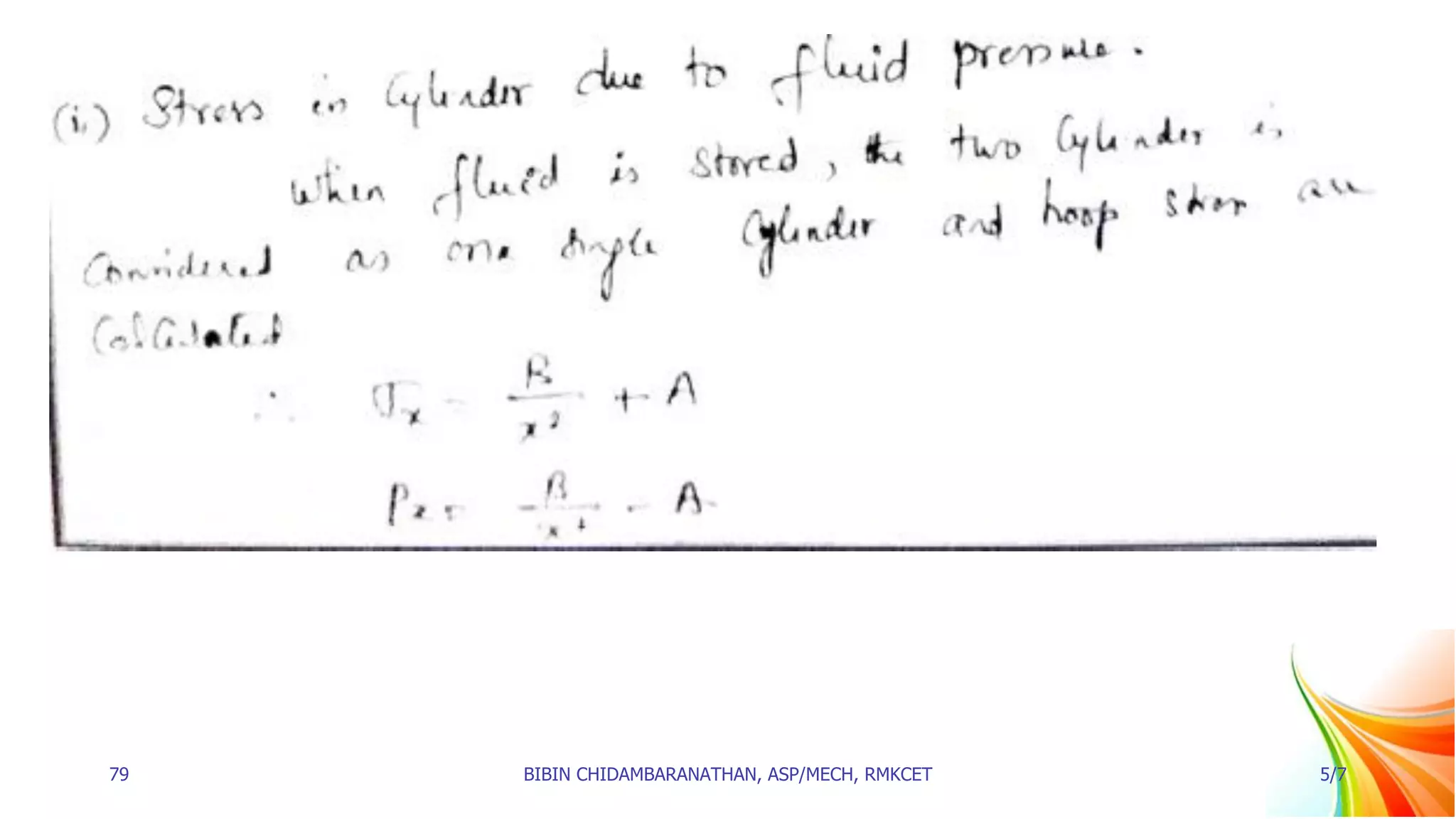

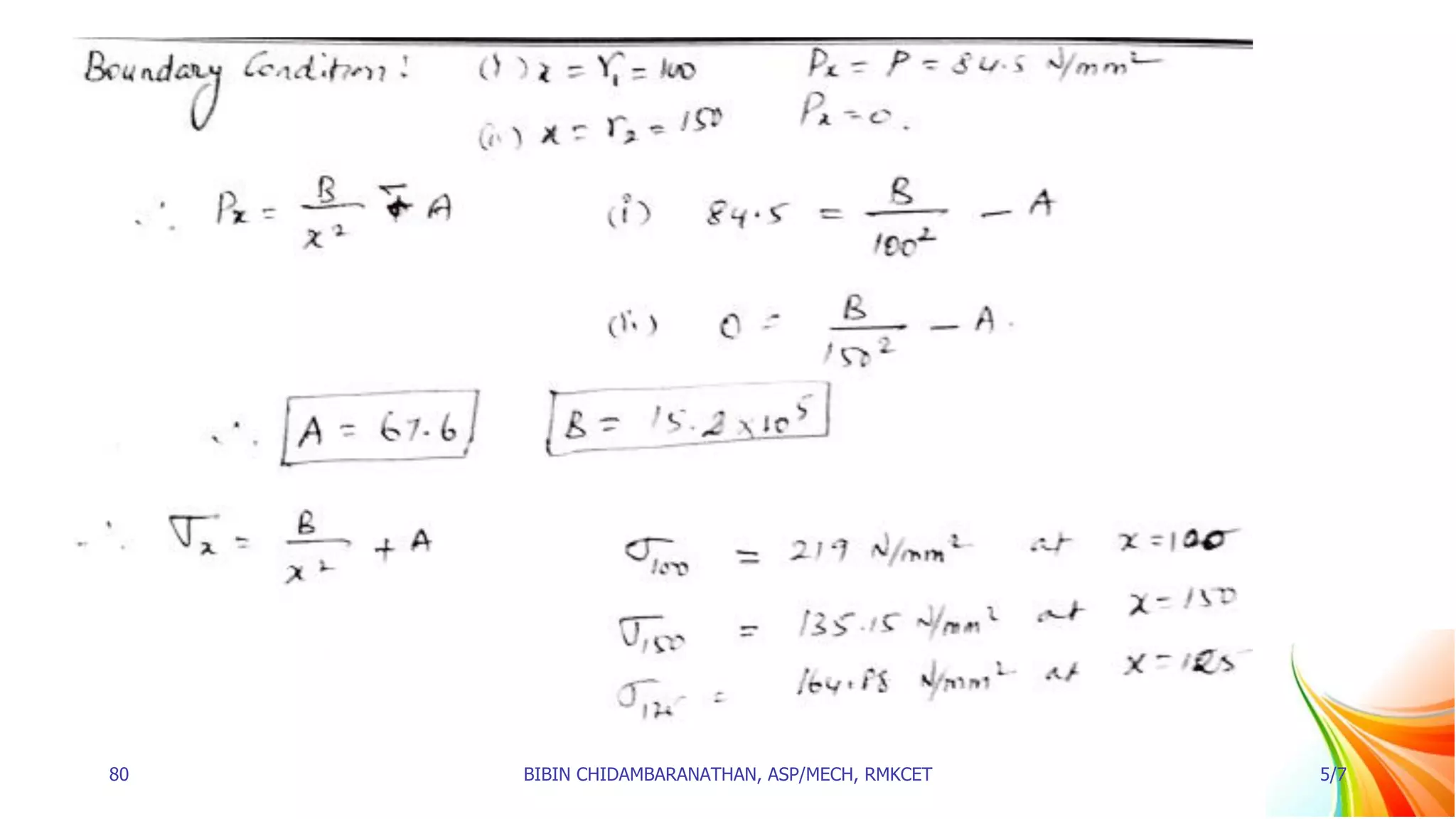

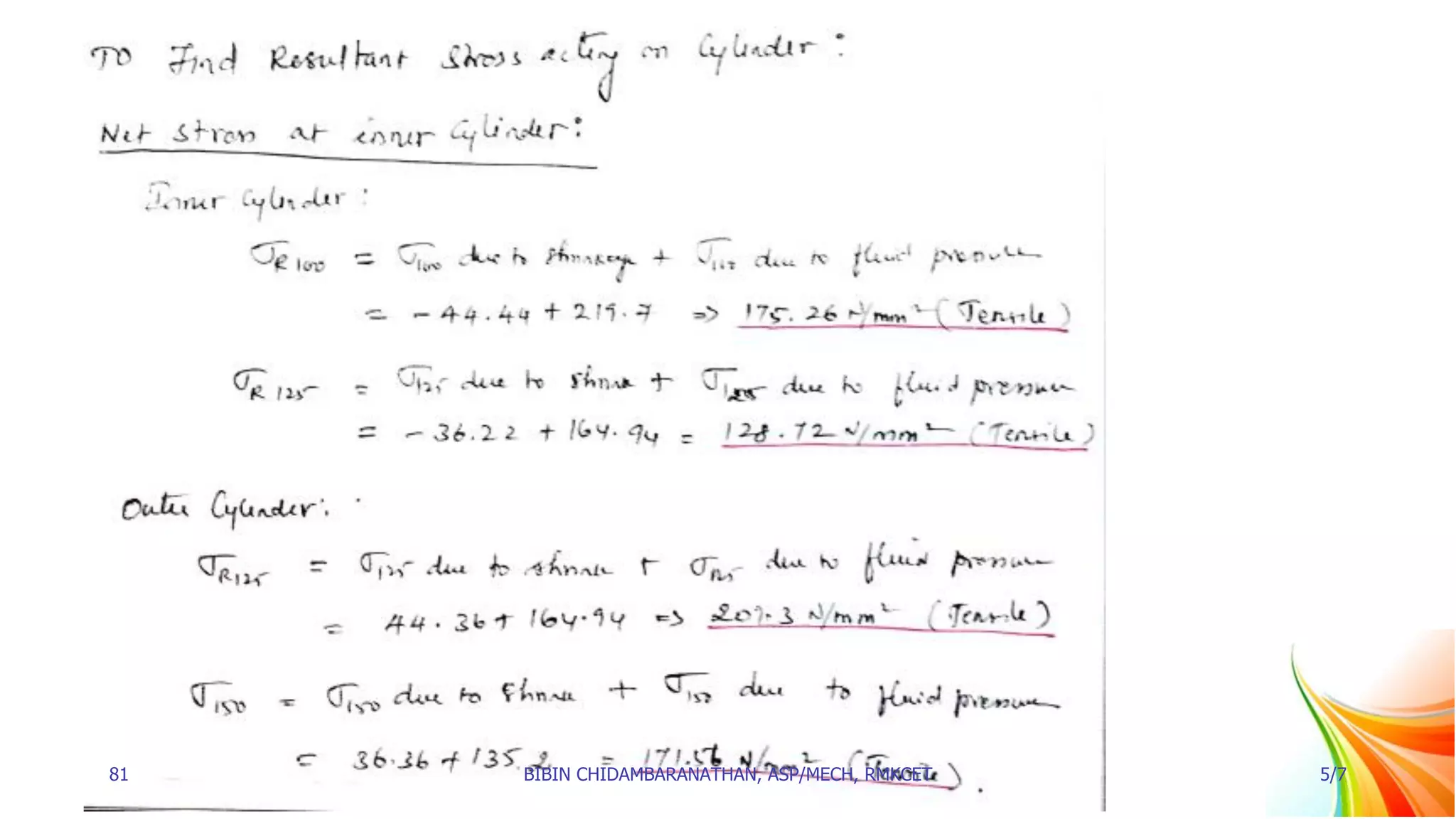

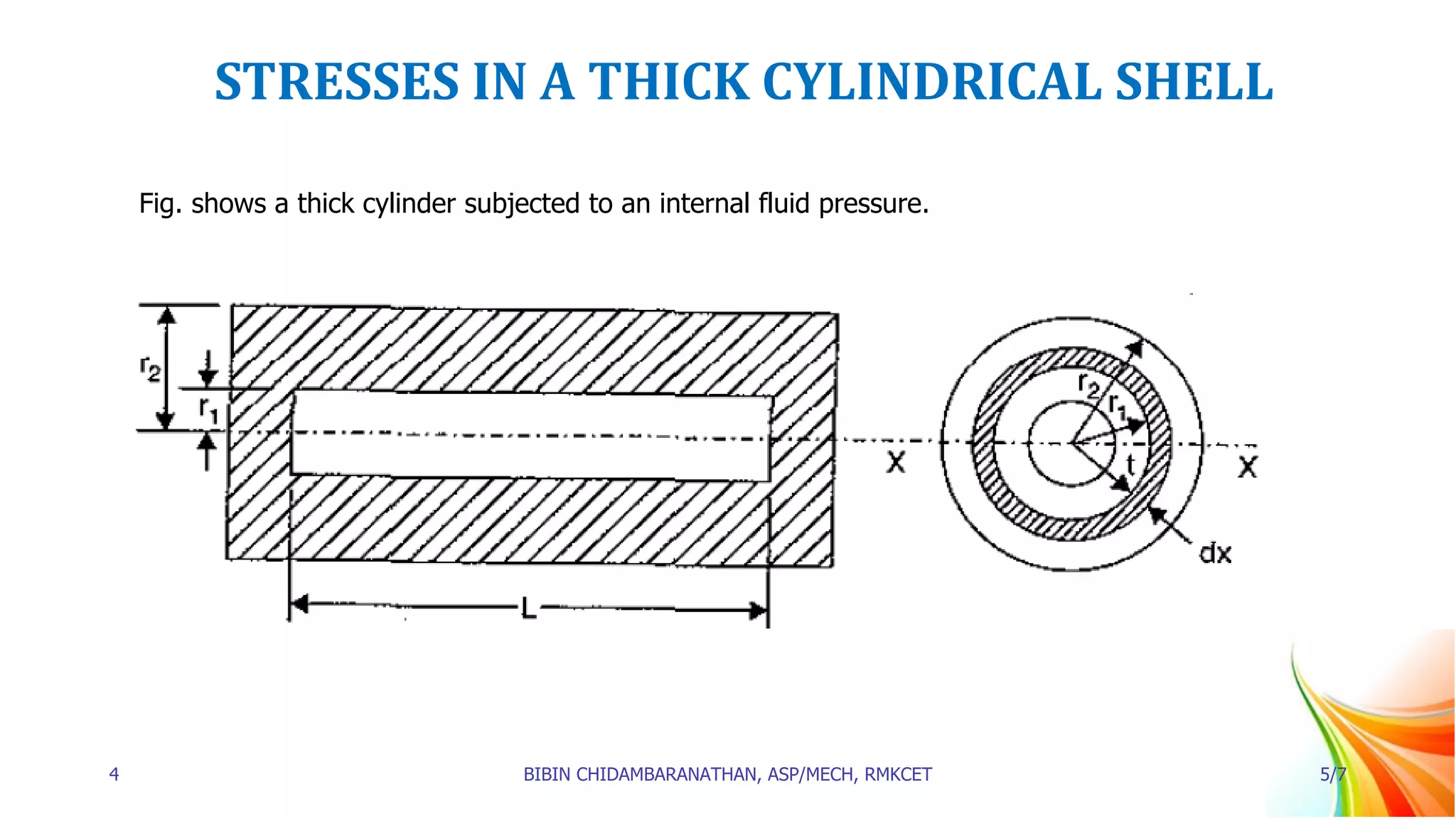

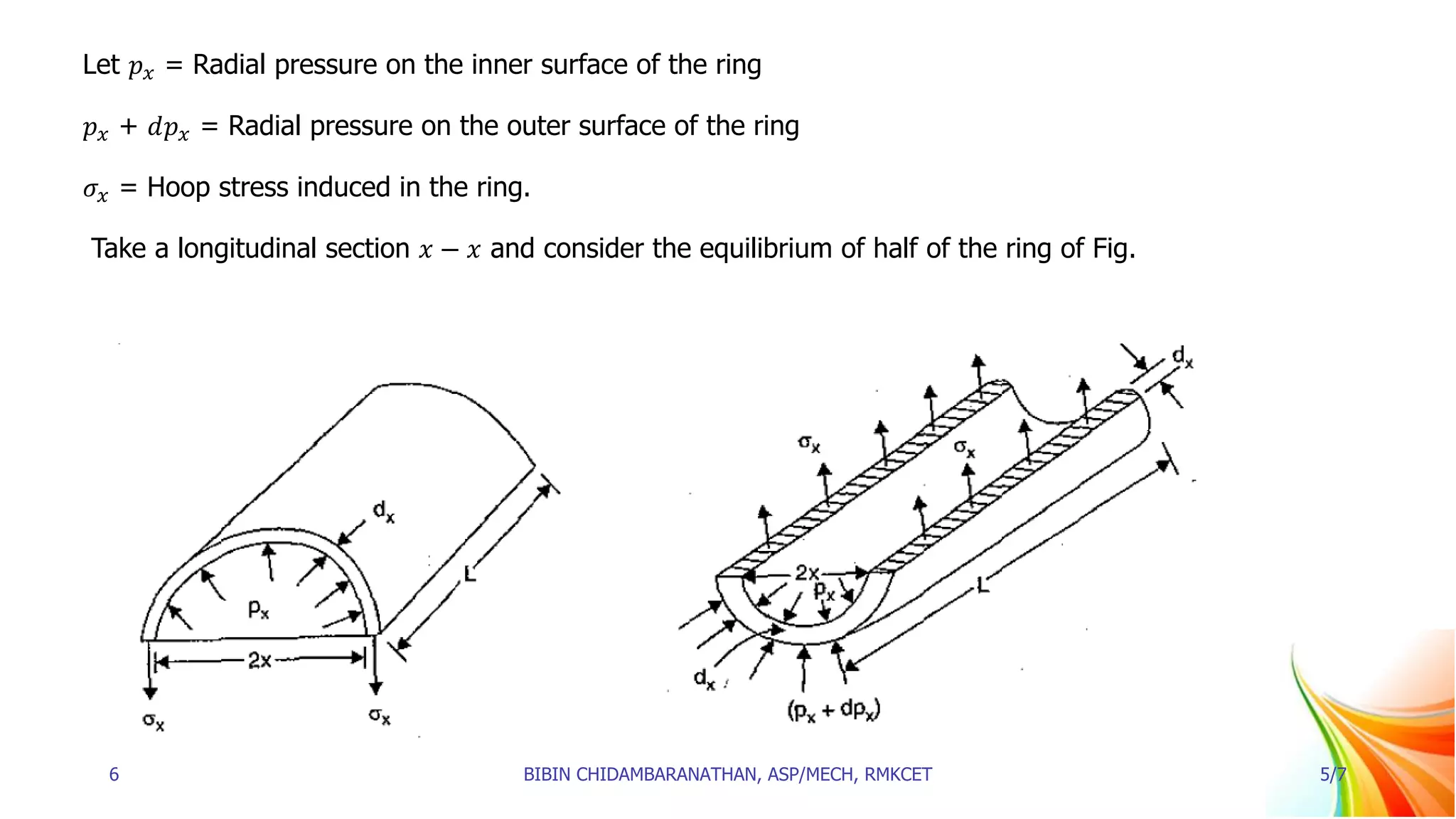

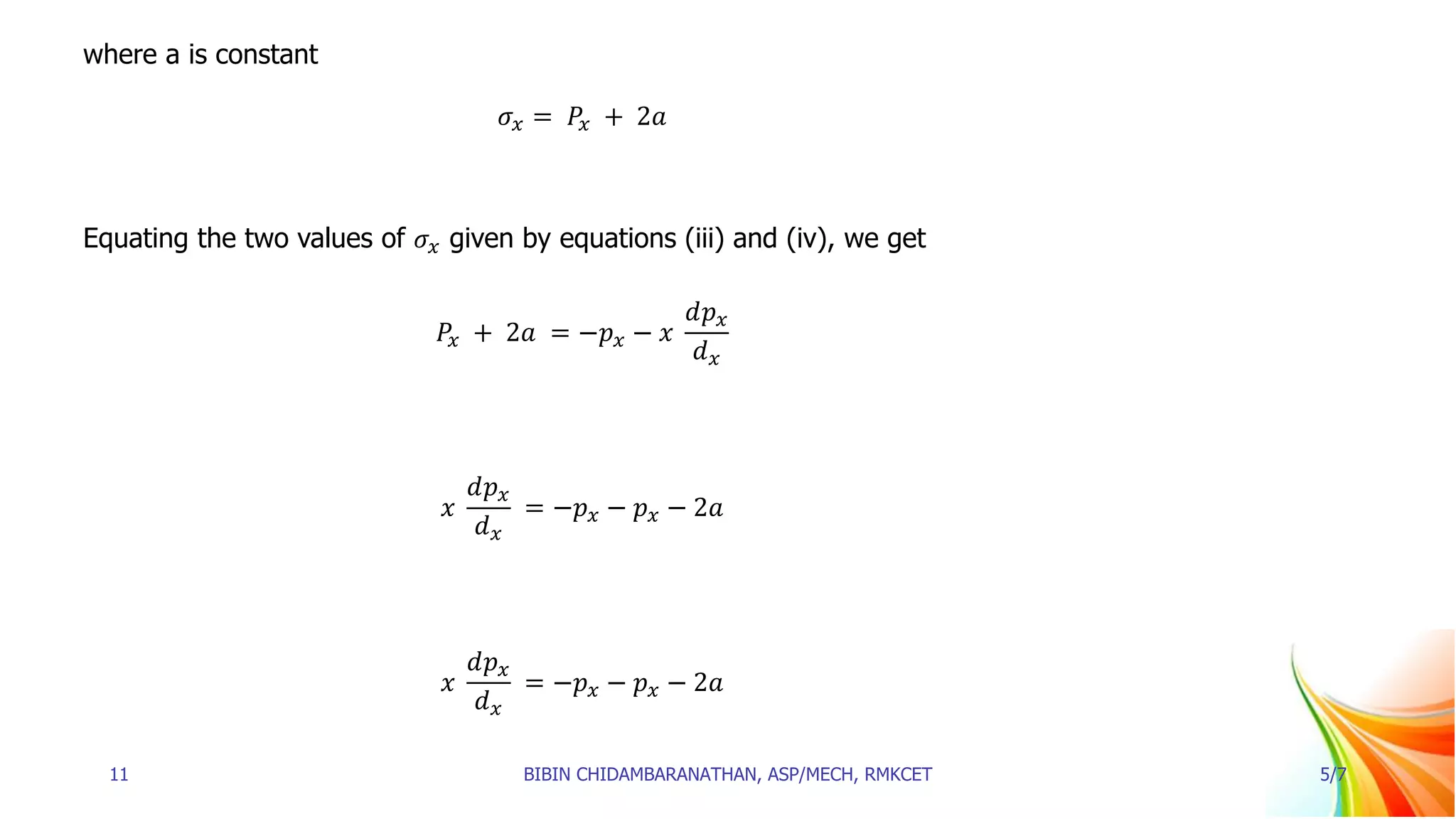

2. Equations are derived for the radial pressure (px) and hoop stress (σx) at any point in a thick cylindrical shell subjected to internal fluid pressure. These equations, known as Lame's equations, define px and σx as functions of radius x.

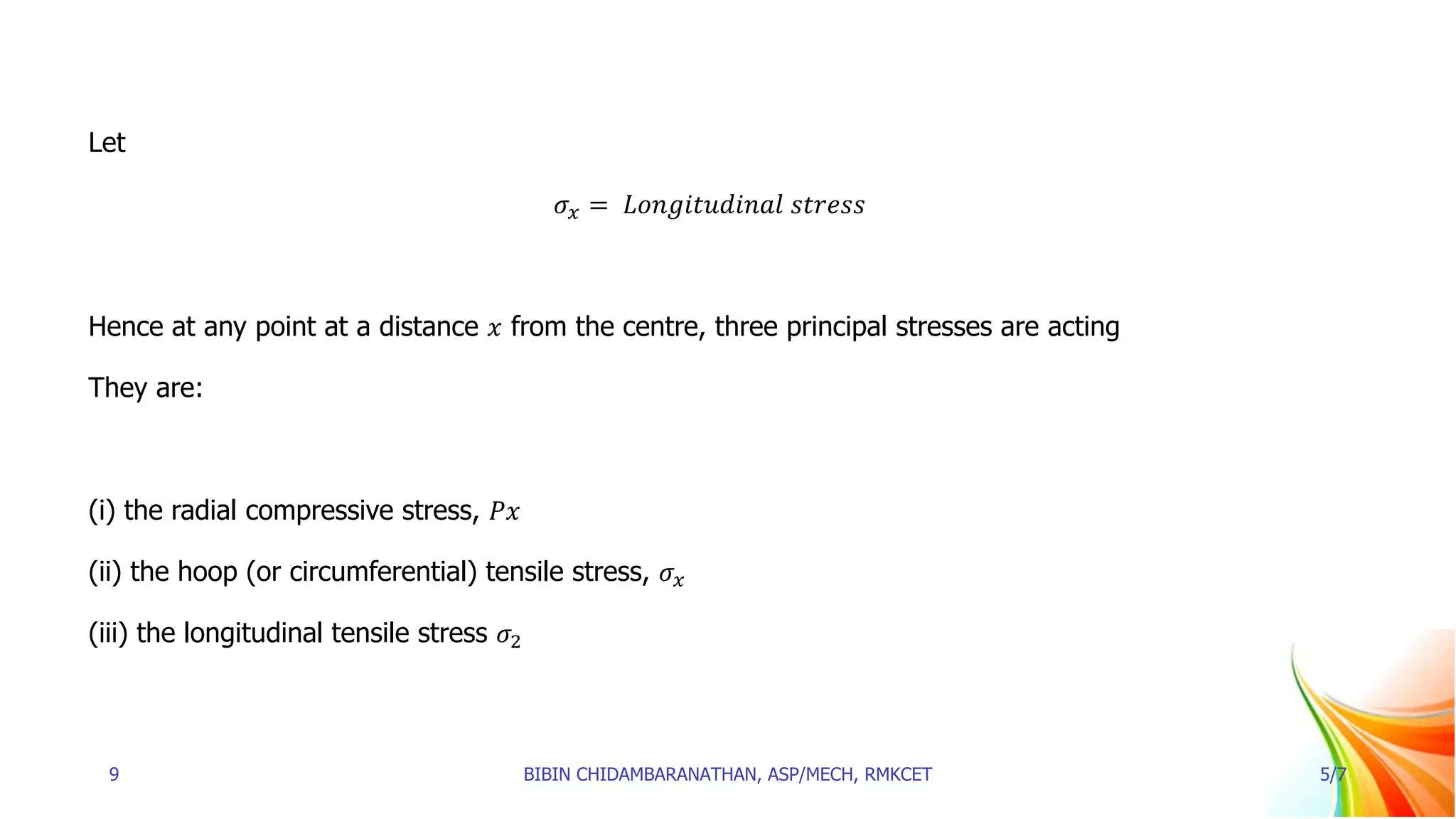

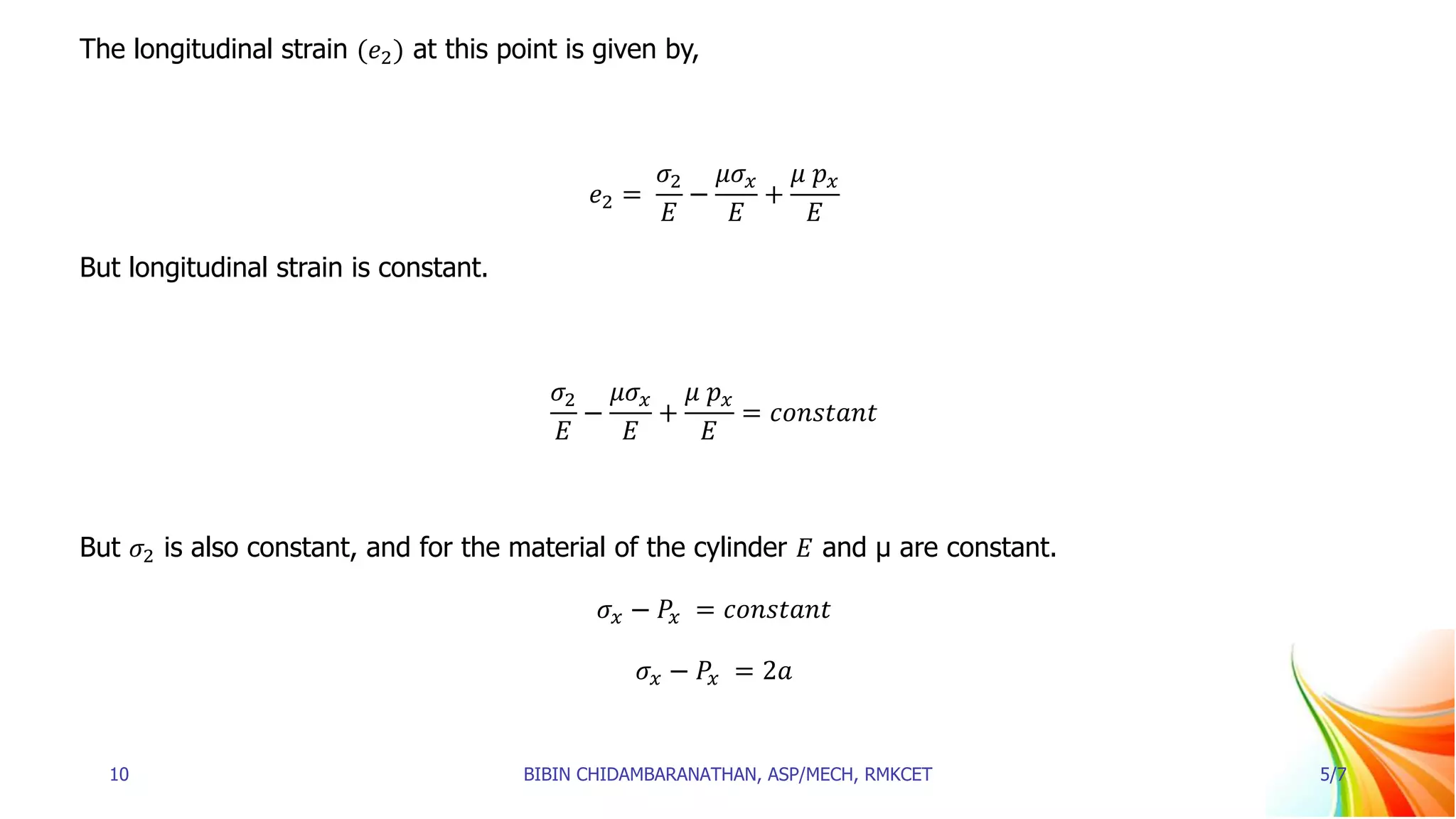

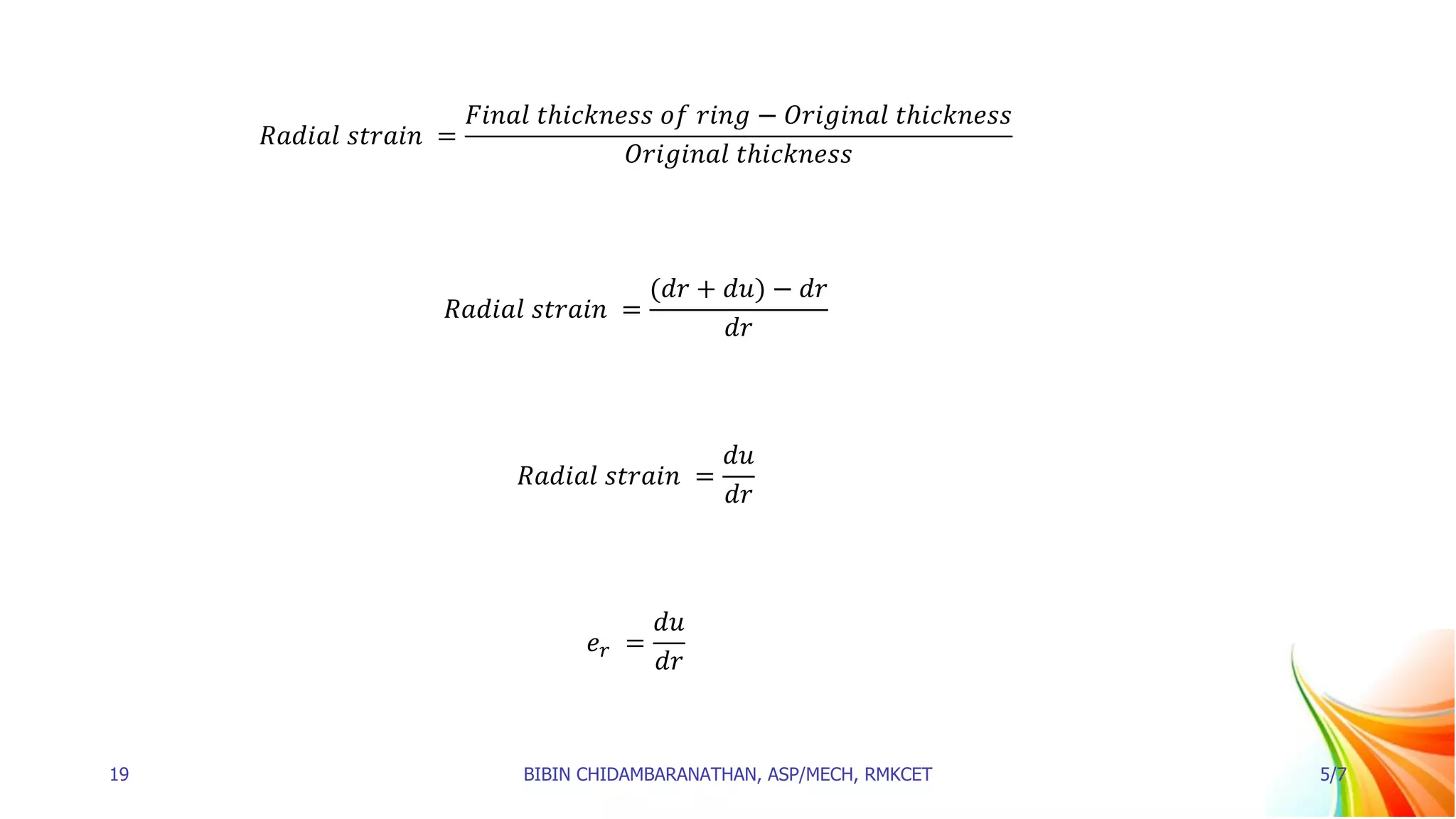

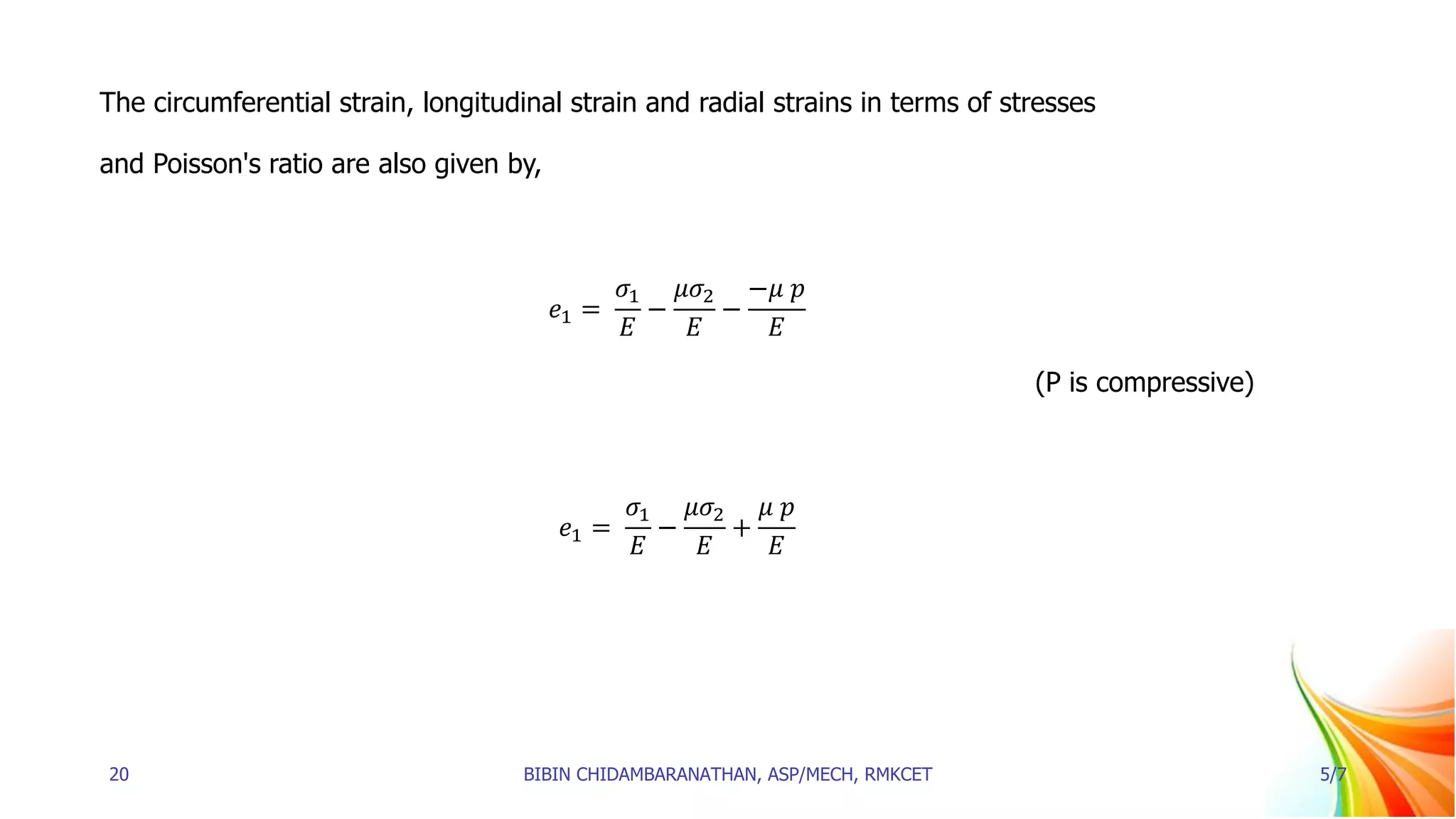

3. An alternate method for finding stresses in a thick cylinder is presented, where circumferential, longitudinal, and radial strains are related to stresses and Poisson's ratio.

![𝐵𝑢𝑟𝑠𝑡𝑖𝑛𝑔 𝑓𝑜𝑟𝑐𝑒 = 𝑝𝑥 (2𝑥𝐿) − (𝑝𝑥 + 𝑑𝑝𝑥) × 2(𝑥 + 𝑑𝑥) . 𝐿

= 2𝐿[𝑝𝑥 . 𝑥 − (𝑝𝑥 . 𝑥 + 𝑝𝑥 . 𝑑𝑥 + 𝑥𝑑𝑝𝑥 + 𝑑𝑝𝑥 − 𝑑𝑥)] .

(Neglecting 𝑑𝑝 . 𝑑𝑥 which is a small quantity)

= 2𝐿[−𝑝𝑥 𝑑𝑥 − 𝑥𝑑𝑝𝑥]

= 2𝐿[𝑝𝑥 𝑑𝑥 + 𝑥𝑑𝑝𝑥]

𝑅𝑒𝑠𝑖𝑠𝑡𝑖𝑛𝑔 𝑓𝑜𝑟𝑐𝑒 = 𝐻𝑜𝑜𝑝 𝑠𝑡𝑟𝑒𝑠𝑠 × 𝐴𝑟𝑒𝑎 𝑜𝑛 𝑤ℎ𝑖𝑐ℎ 𝑖𝑡 𝑎𝑐𝑡𝑠

𝑅𝑒𝑠𝑖𝑠𝑡𝑖𝑛𝑔 𝑓𝑜𝑟𝑐𝑒 = 𝜎𝑥 × 2𝑑𝑥. 𝐿

7 BIBIN CHIDAMBARANATHAN, ASP/MECH, RMKCET 5/7](https://image.slidesharecdn.com/lecture37som07-210819075301/75/Lecture-37-som-07-05-2021-7-2048.jpg)

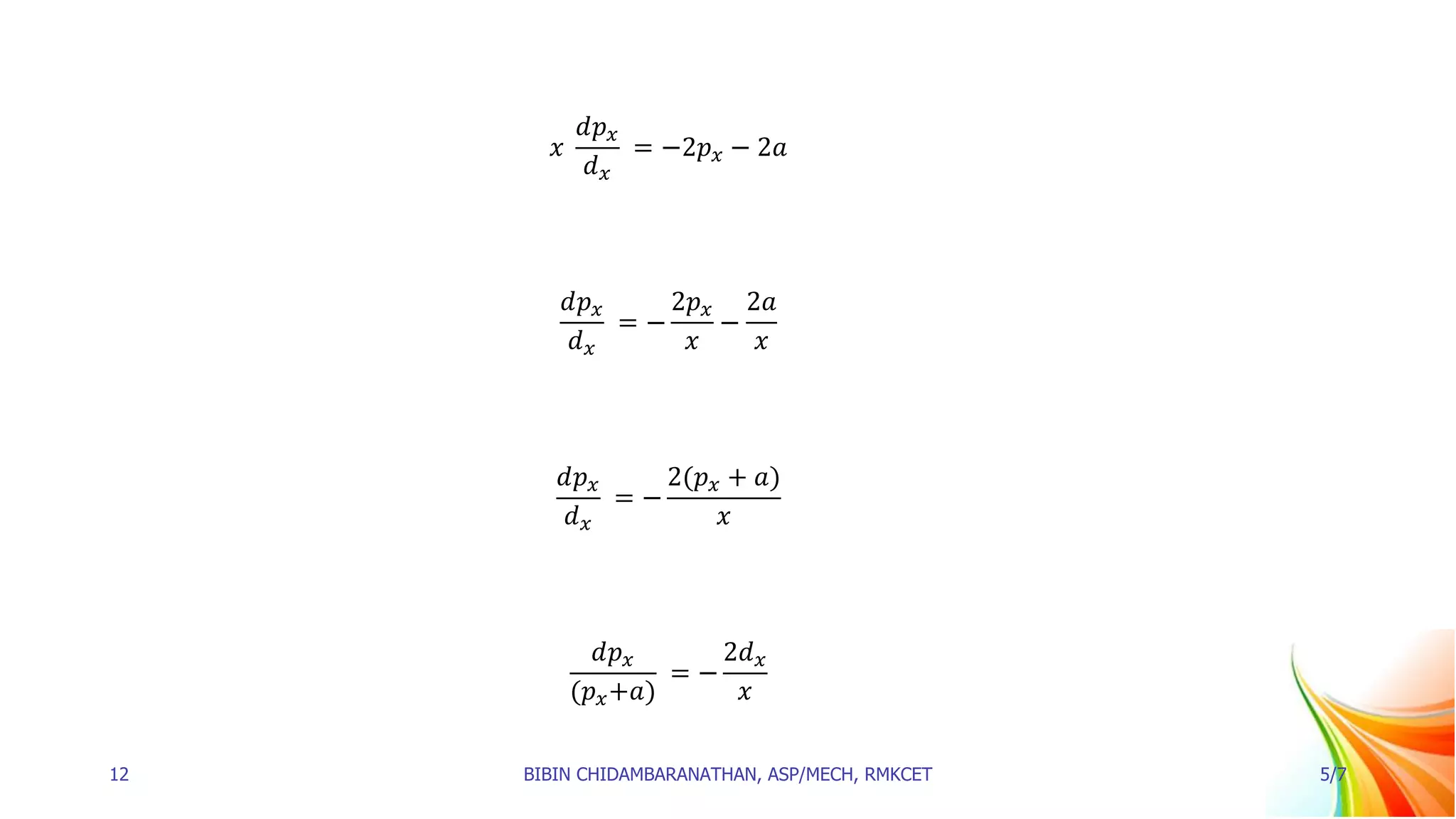

![Equating the resisting force to the bursting force, we get

𝜎𝑥 × 2𝑑𝑥. 𝐿 = 2𝐿[𝑝𝑥 𝑑𝑥 + 𝑥𝑑𝑝𝑥]

𝜎𝑥 = −𝑝𝑥 − 𝑥

𝑑𝑝𝑥

𝑑𝑥

The longitudinal strain at any point in the section is constant and is independent of the radius. This

means that cross sections remain plane after straining and this is true for sections, remote from any end

fixing. As longitudinal strain is constant, hence longitudinal stress will also be constant.

8 BIBIN CHIDAMBARANATHAN, ASP/MECH, RMKCET 5/7](https://image.slidesharecdn.com/lecture37som07-210819075301/75/Lecture-37-som-07-05-2021-8-2048.jpg)

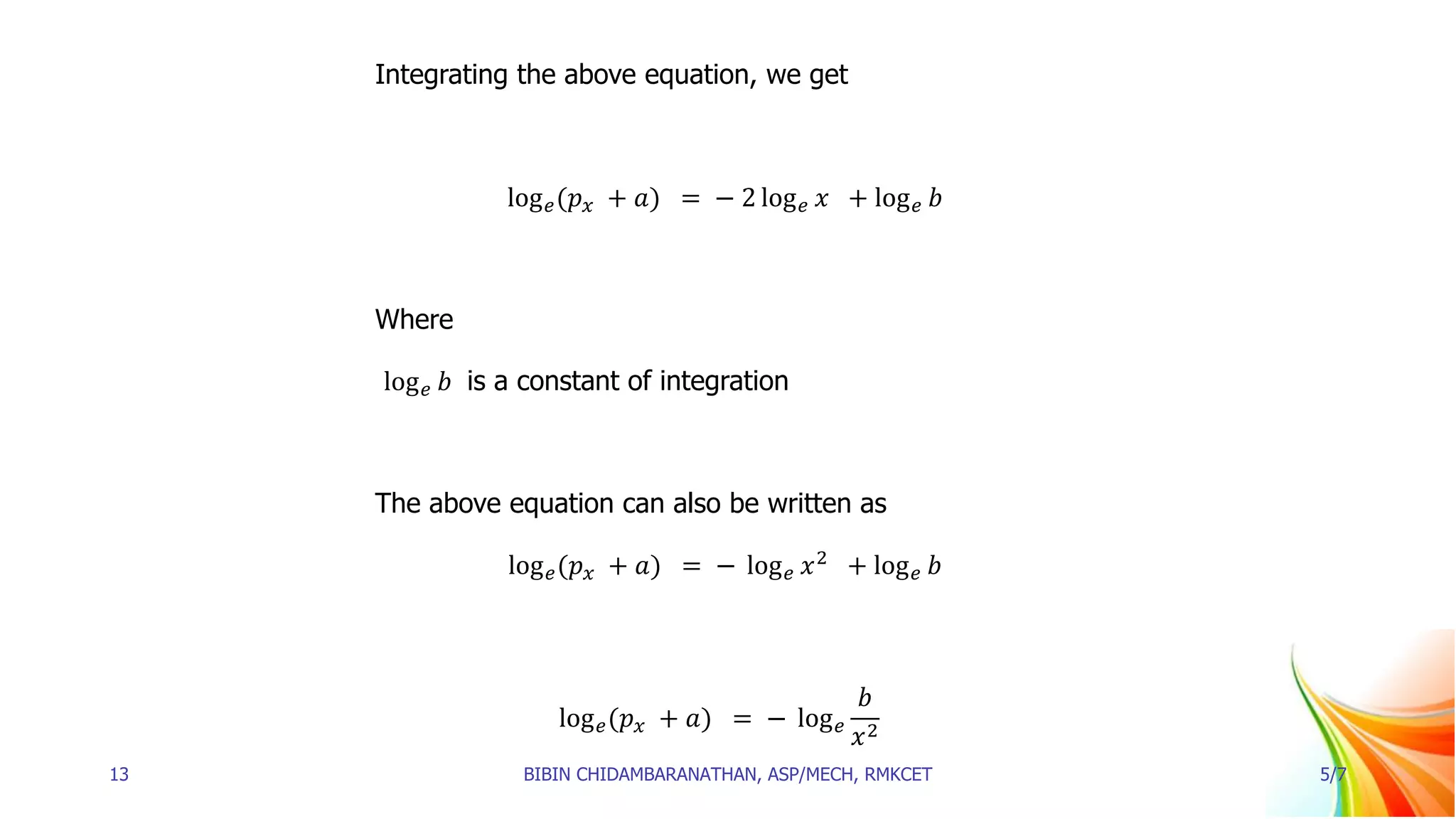

![𝑑𝑢

𝑑𝑟

=

−𝑝

𝐸

−

𝜇𝜎1

𝐸

+

𝜇𝜎2

𝐸

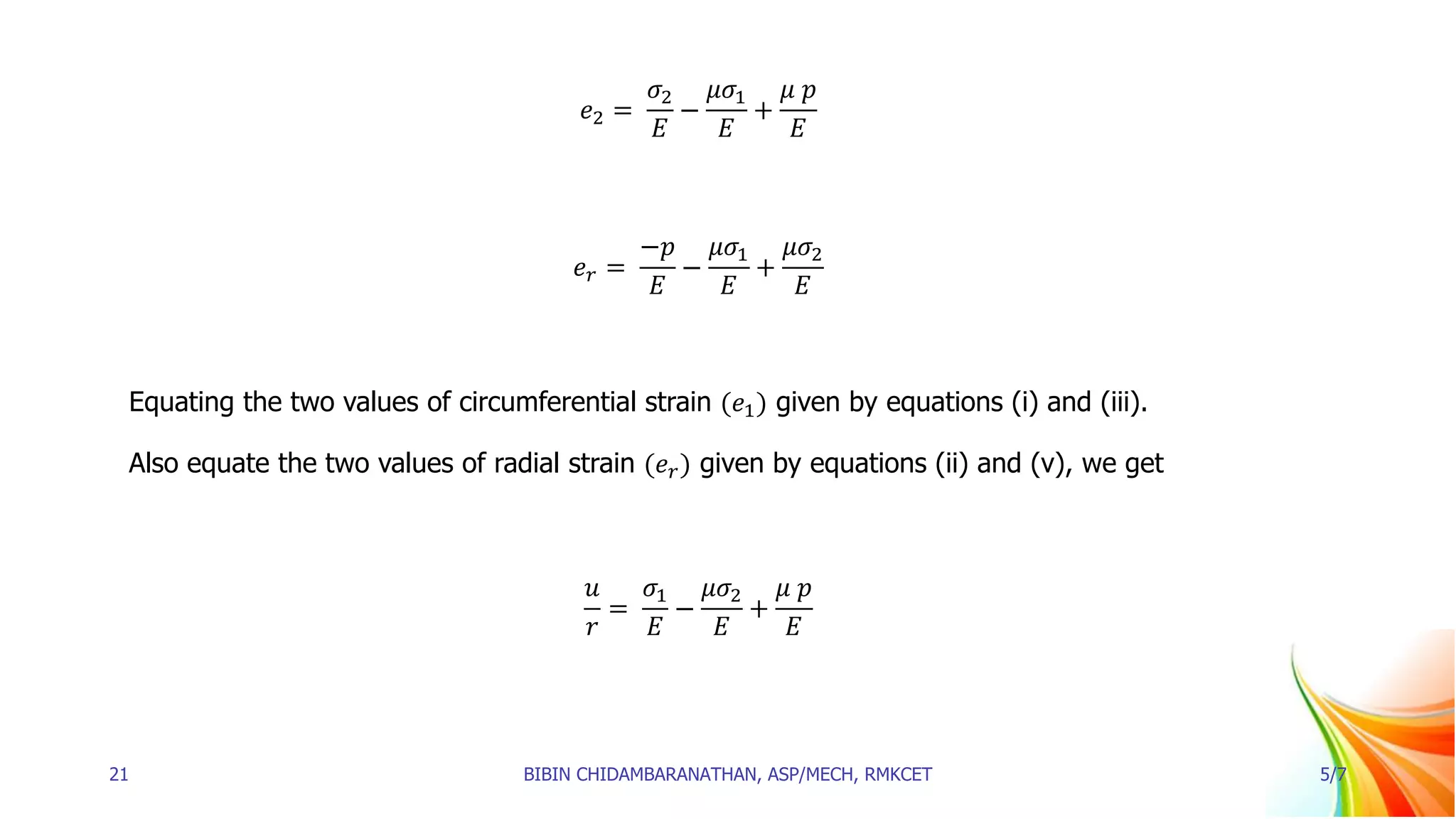

Let us first eliminate 'u' from equations (vi) and (vii). From equation (vi),

𝑢 = [

𝜎1

𝐸

−

𝜇𝜎2

𝐸

+

𝜇 𝑝

𝐸

] × 𝑟

Differentiating the above equation with respect to r, we get

𝑑𝑢

𝑑𝑟

=

𝜎1

𝐸

−

𝜇𝜎2

𝐸

+

𝜇 𝑝

𝐸

+

𝑟

𝐸

(

𝑑𝜎1

𝑑𝑟

−

𝜇 𝑑𝜎2

𝑑𝑟

+

𝜇 𝑑𝑝

𝑑𝑟

)

22 BIBIN CHIDAMBARANATHAN, ASP/MECH, RMKCET 5/7](https://image.slidesharecdn.com/lecture37som07-210819075301/75/Lecture-37-som-07-05-2021-22-2048.jpg)

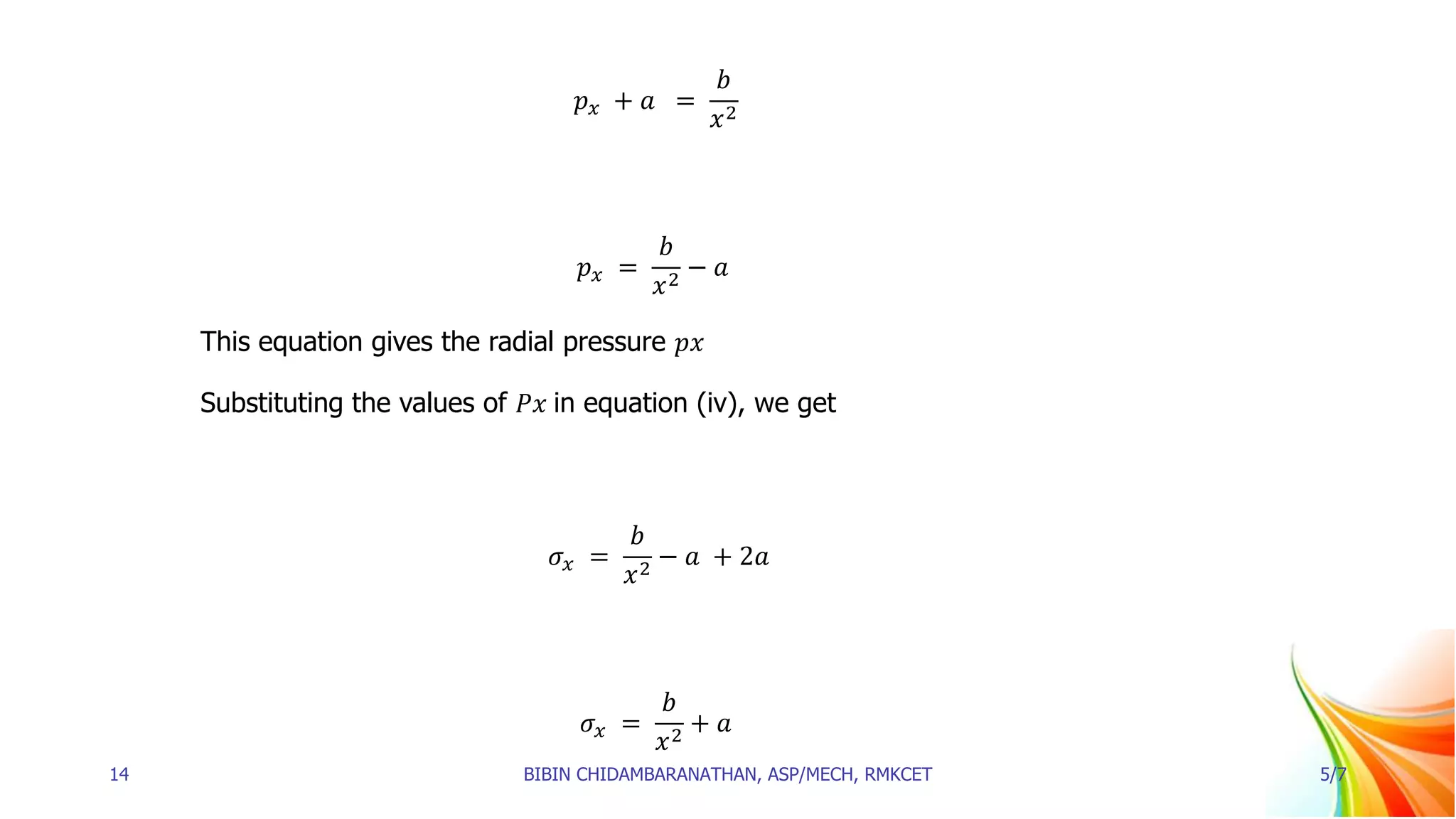

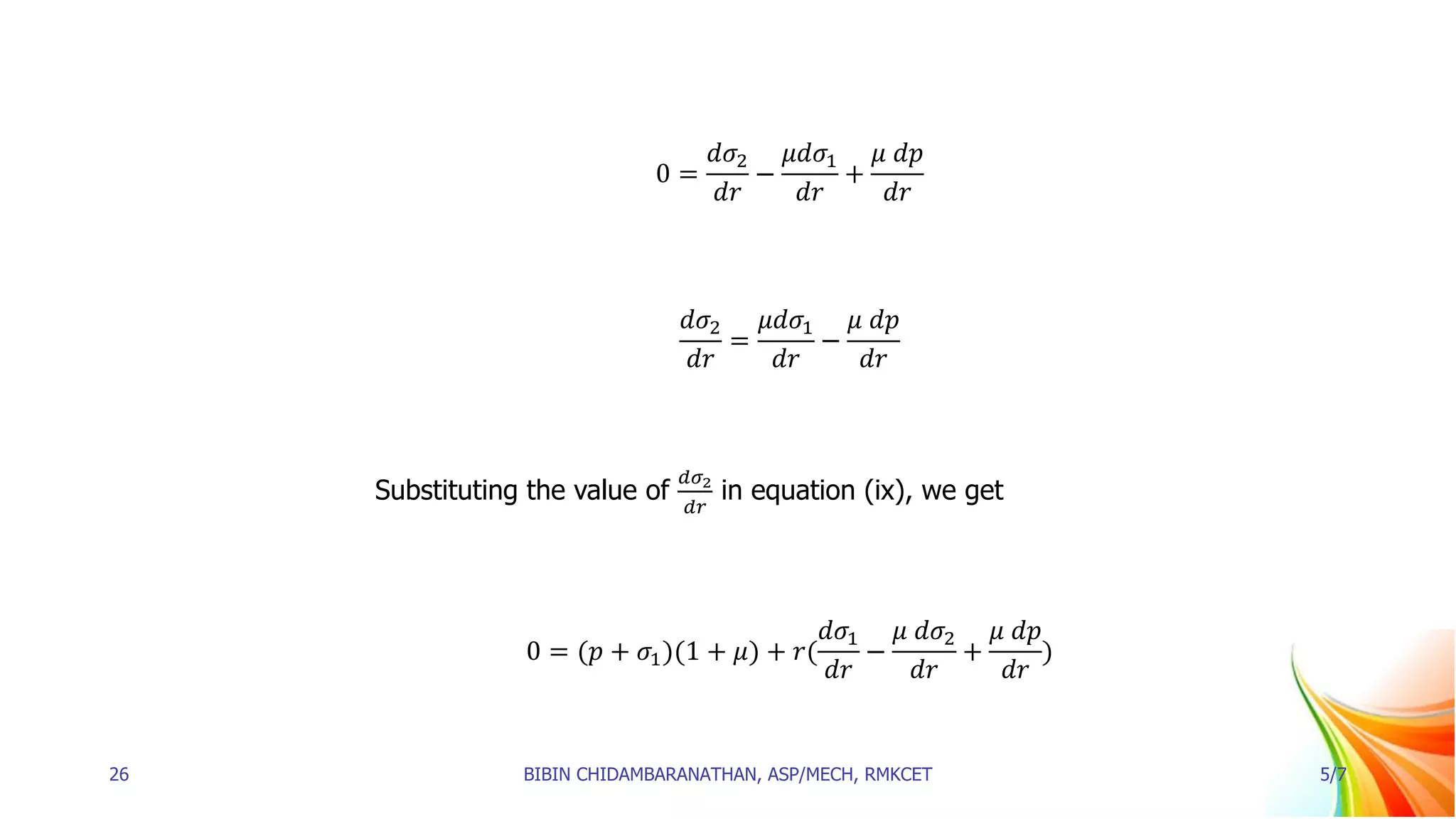

![To find the value of 𝜎1 in terms of p, the value of

𝑑𝜎2

𝑑𝑟

must be substituted in the above

equation (ix).

Longitudinal strain (𝑒2) is given by equation (iv) as

𝑒2 =

𝜎2

𝐸

−

𝜇𝜎1

𝐸

+

𝜇 𝑝

𝐸

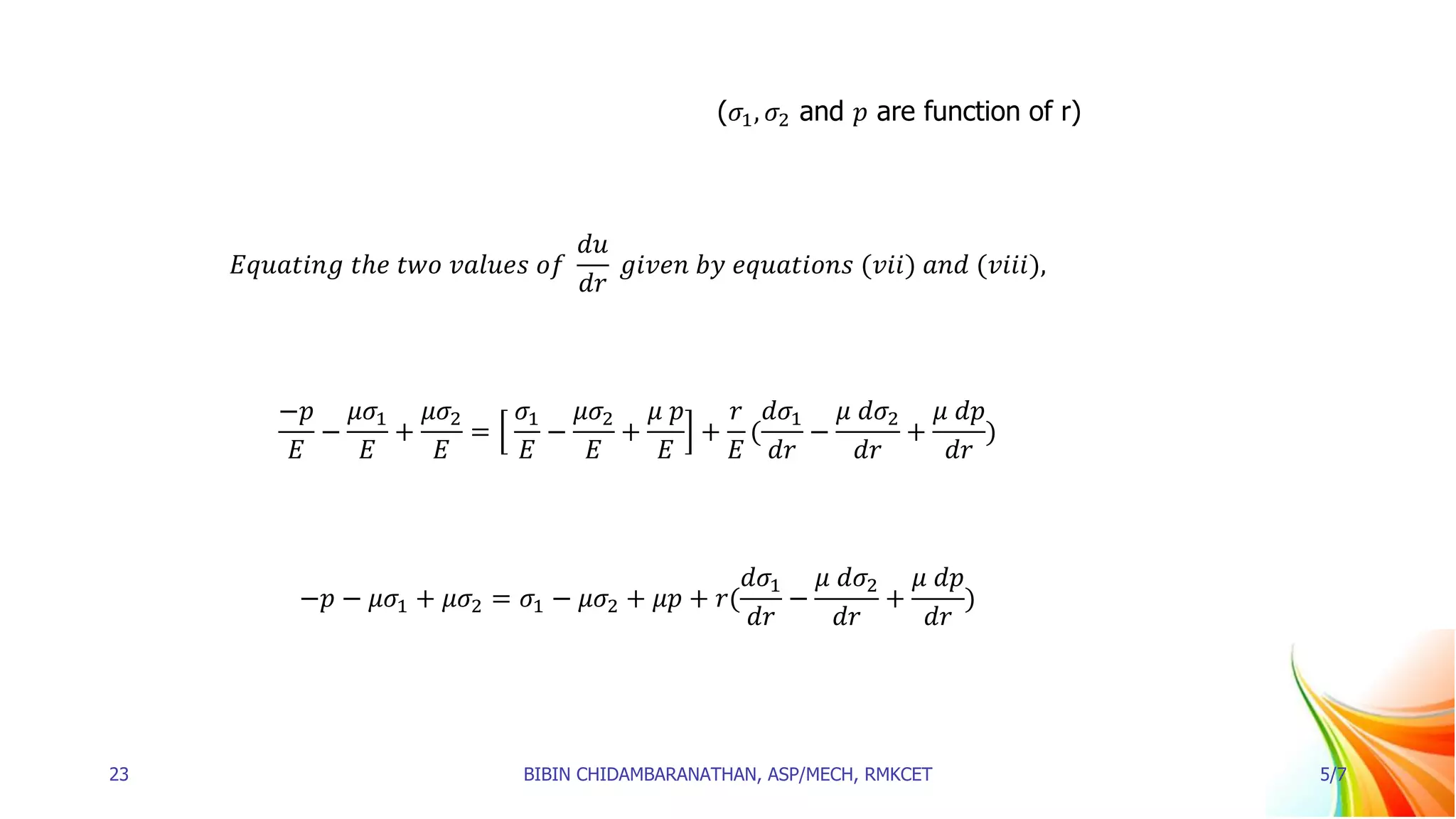

Since longitudinal strain (𝑒2) is assumed constant. Its differentiation with respect to r will be

zero. D1fferentiating the above equation with respect to 'r', we get

0 =

1

𝐸

[

𝑑𝜎2

𝑑𝑟

−

𝜇𝑑𝜎1

𝑑𝑟

+

𝜇 𝑑𝑝

𝑑𝑟

]

25 BIBIN CHIDAMBARANATHAN, ASP/MECH, RMKCET 5/7](https://image.slidesharecdn.com/lecture37som07-210819075301/75/Lecture-37-som-07-05-2021-25-2048.jpg)

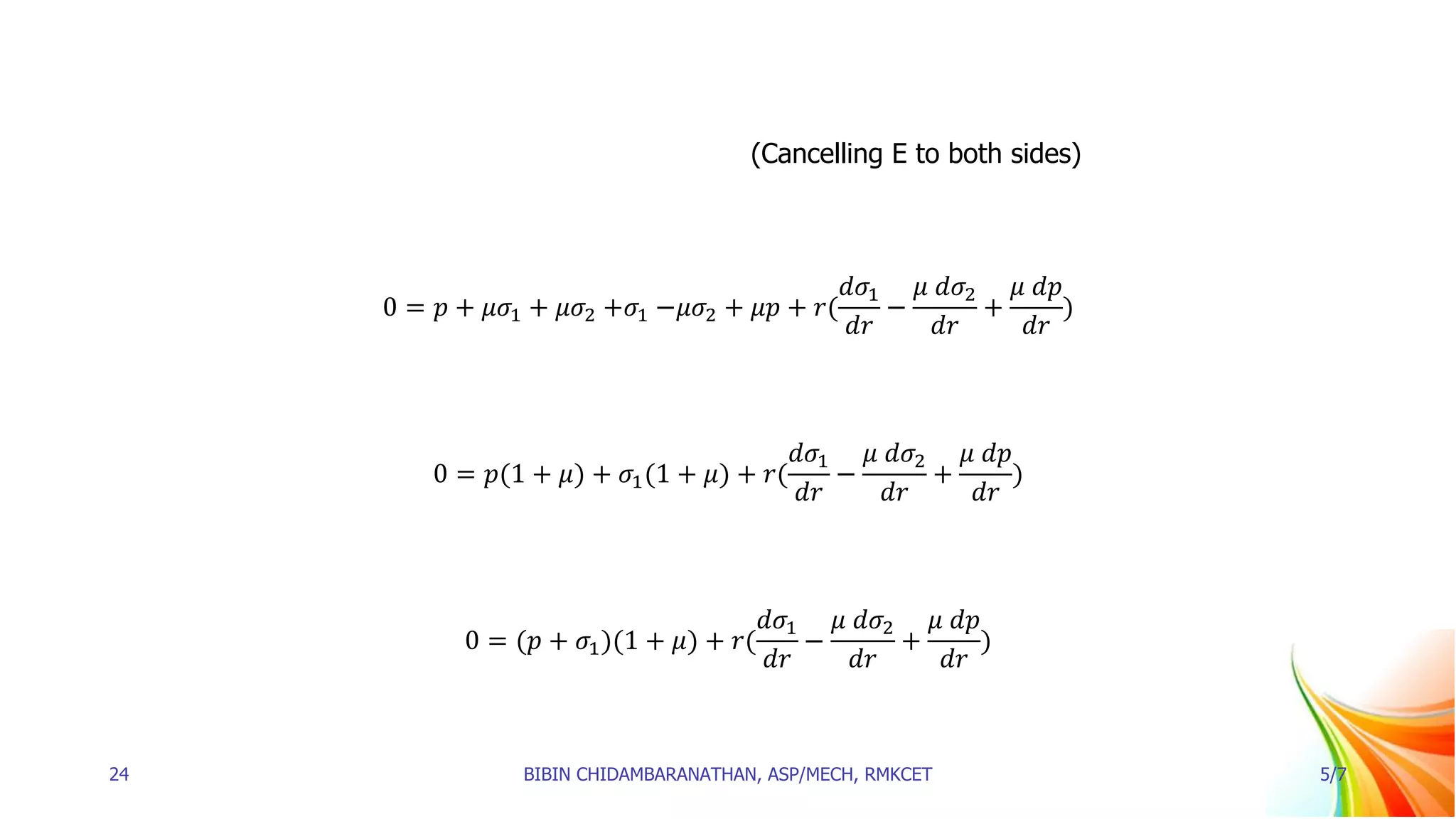

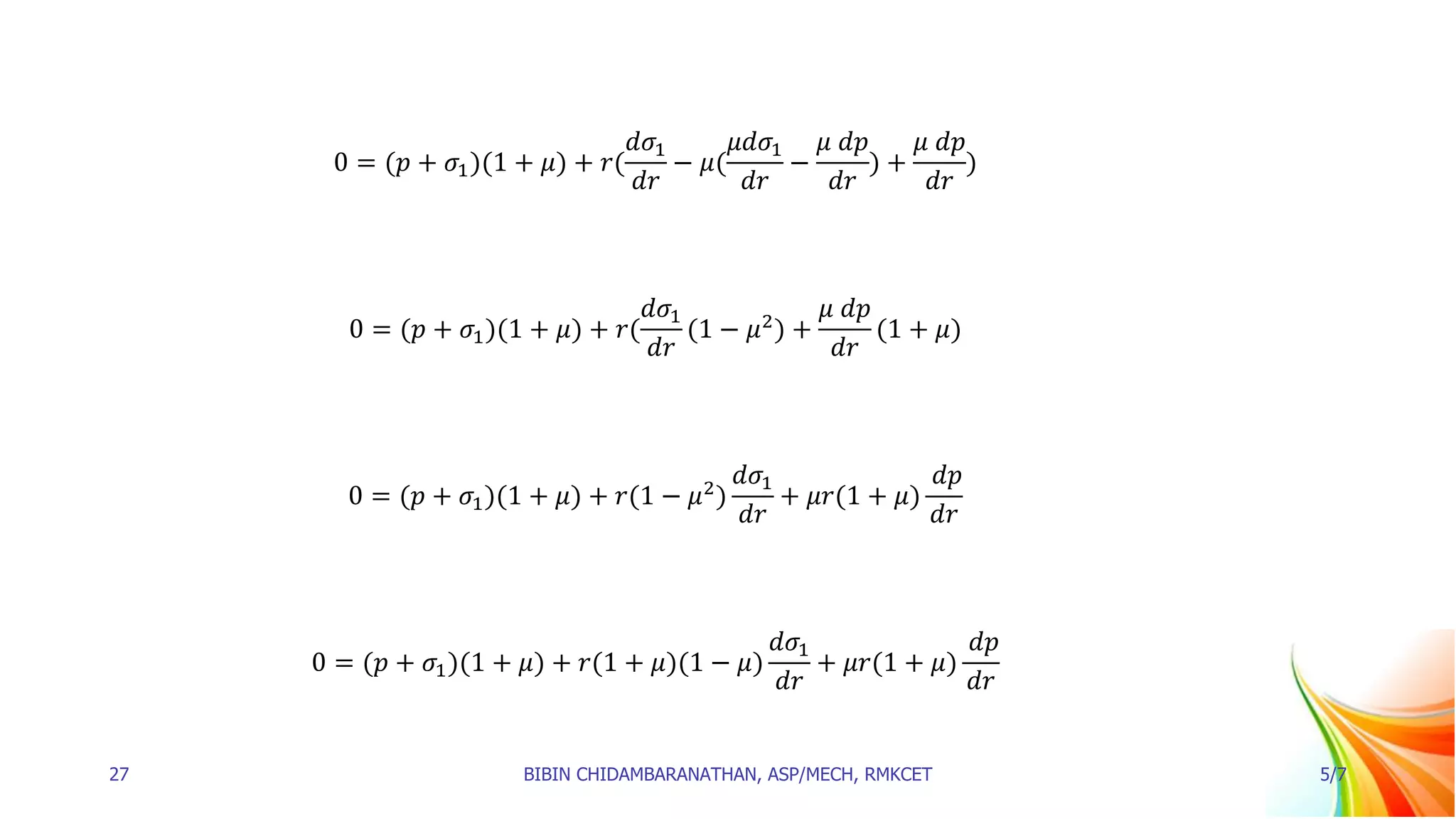

![0 = (𝑝 + 𝜎1)(1 + 𝜇) + 𝑟(1 + 𝜇)(1 − 𝜇)

𝑑𝜎1

𝑑𝑟

+ 𝜇𝑟(1 + 𝜇)

𝑑𝑝

𝑑𝑟

0 = 1 + 𝜇 [(𝑝 + 𝜎1) + 𝑟(1 − 𝜇)

𝑑𝜎1

𝑑𝑟

+ 𝜇𝑟

𝑑𝑝

𝑑𝑟

]

(1 + 𝜇) ≠ 0

0 = (𝑝 + 𝜎1) + 𝑟(1 − 𝜇)

𝑑𝜎1

𝑑𝑟

+ 𝜇𝑟

𝑑𝑝

𝑑𝑟

28 BIBIN CHIDAMBARANATHAN, ASP/MECH, RMKCET 5/7](https://image.slidesharecdn.com/lecture37som07-210819075301/75/Lecture-37-som-07-05-2021-28-2048.jpg)

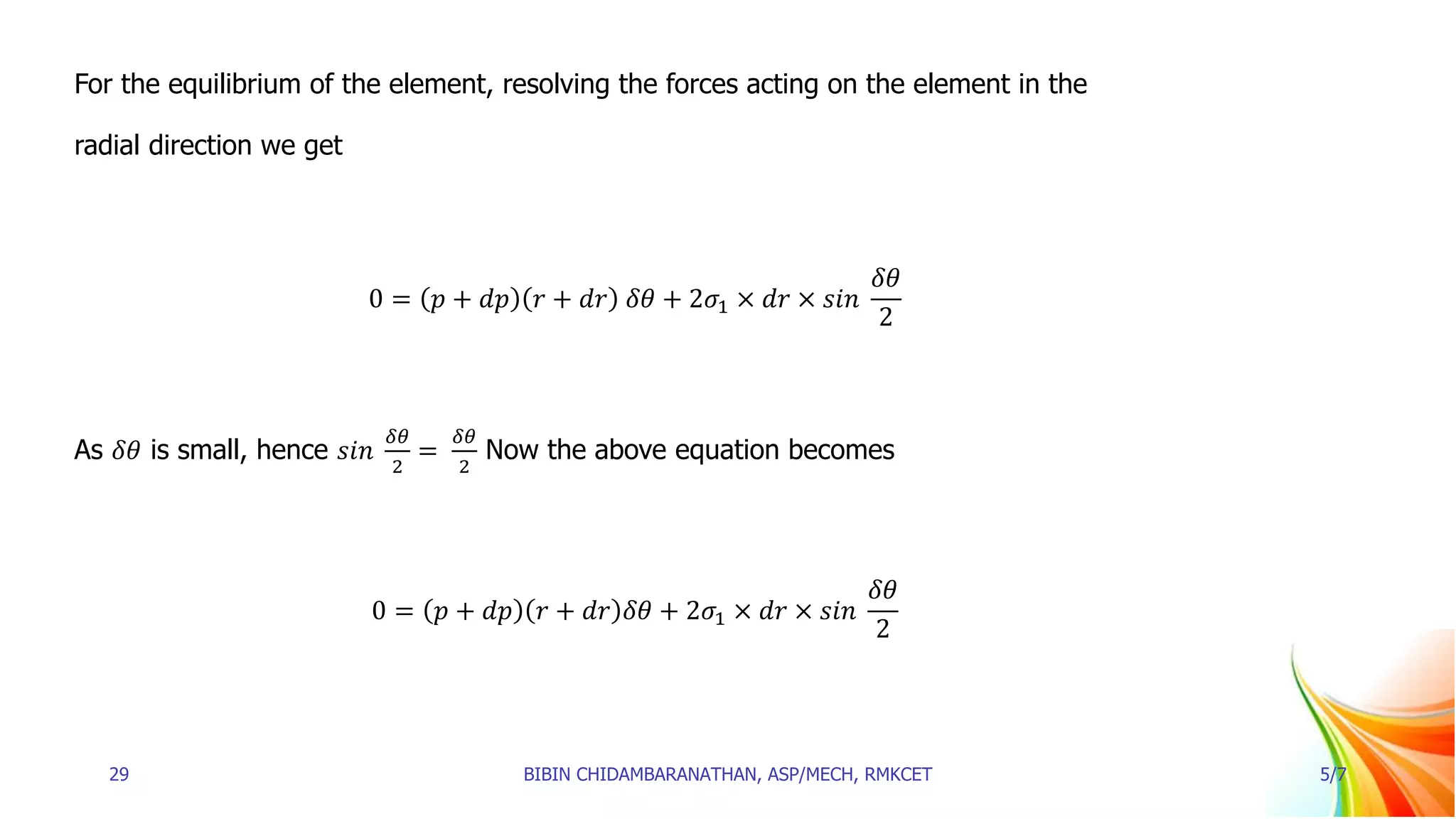

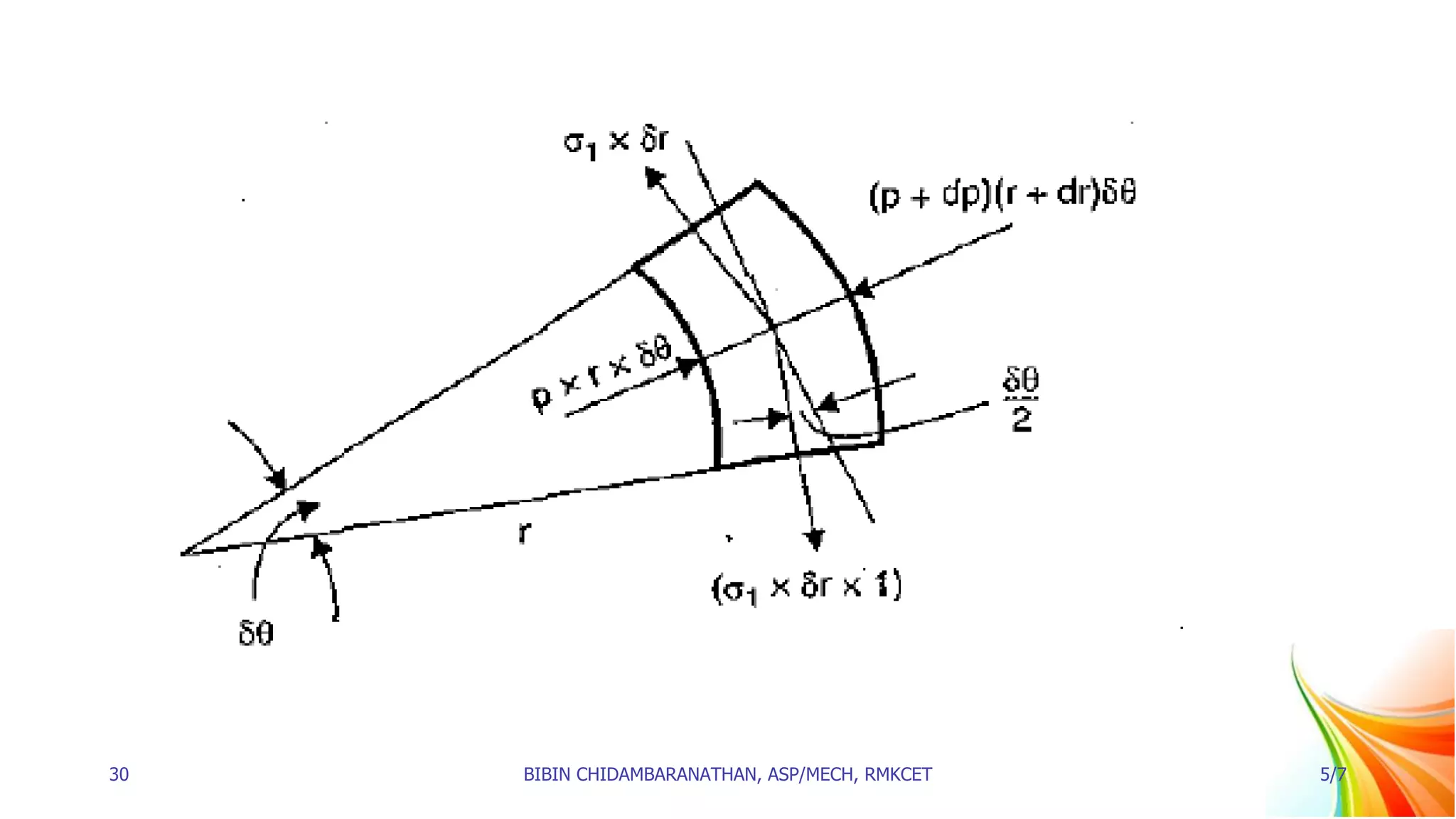

![𝑝 + 𝑑𝑝 𝑟 + 𝑑𝑟 𝛿𝜃 + 𝑝𝑟𝛿𝜃 + 2𝜎1 × 𝑑𝑟 ×

𝛿𝜃

2

= 0

𝑝 + 𝑑𝑝 𝑟 + 𝑑𝑟 − 𝑝𝑟 + 𝜎1 × 𝑑𝑟 = 0

𝑝𝑟 + 𝑝𝑑𝑟 + 𝑟𝑑𝑝 + 𝑑𝑝 × 𝑑𝑟 − 𝑝𝑟 + 𝜎1 × 𝑑𝑟 = 0

𝑝𝑑𝑟 + 𝑟𝑑𝑝 + 𝜎1𝑑𝑟 = 0

[dp x dr is the product of two small quantities and can be neglected]

31 BIBIN CHIDAMBARANATHAN, ASP/MECH, RMKCET 5/7](https://image.slidesharecdn.com/lecture37som07-210819075301/75/Lecture-37-som-07-05-2021-31-2048.jpg)

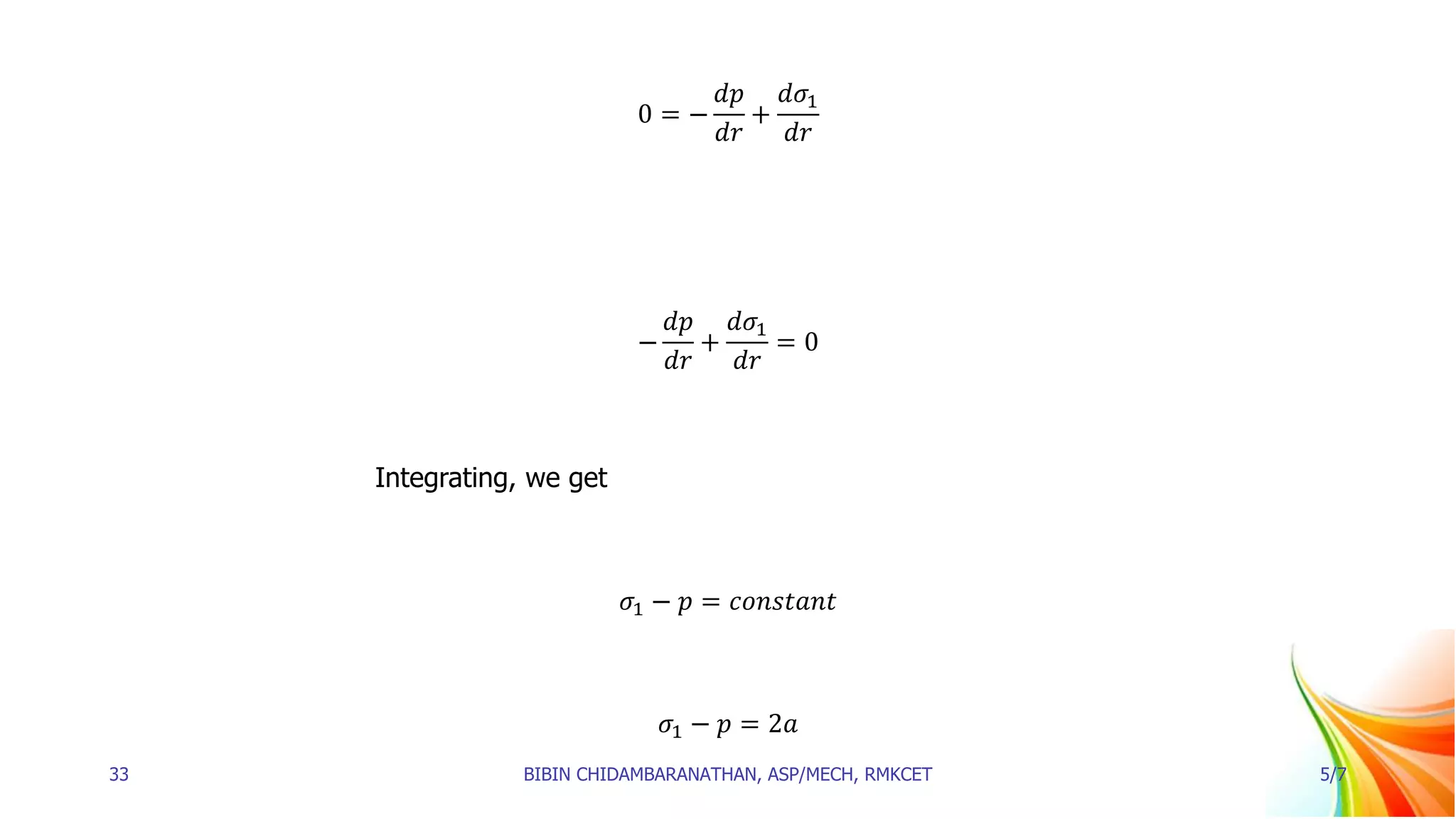

![𝑝 + 𝑟

𝑑𝑝

𝑑𝑟

+ 𝜎1 = 0

𝑝 + 𝜎1 = −𝑟

𝑑𝑝

𝑑𝑟

Substituting the value of 𝑝 + 𝜎1 in equation (𝑥), we get

0 = (𝑝 + 𝜎1) + 𝑟(1 − 𝜇)

𝑑𝜎1

𝑑𝑟

+ 𝜇𝑟

𝑑𝑝

𝑑𝑟

0 = −𝑟

𝑑𝑝

𝑑𝑟

1 − 𝜇 + 𝑟(1 − 𝜇)

𝑑𝜎1

𝑑𝑟

[Cancelling 𝑟(1 – 𝜇) to both sides]

32 BIBIN CHIDAMBARANATHAN, ASP/MECH, RMKCET 5/7](https://image.slidesharecdn.com/lecture37som07-210819075301/75/Lecture-37-som-07-05-2021-32-2048.jpg)