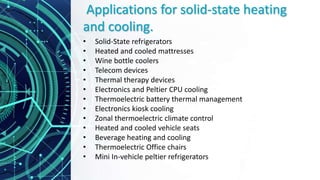

Solid-state thermoelectric devices, also known as Peltier coolers, efficiently manage heating and cooling without moving parts, making them reliable and environmentally friendly. These devices can heat and cool by reversing electrical current and are scalable for various applications, including refrigeration, climate control, and medical uses. Key advantages include high efficiency, precise temperature control, silent operation, and no need for refrigerants, enhancing design flexibility and customer satisfaction.