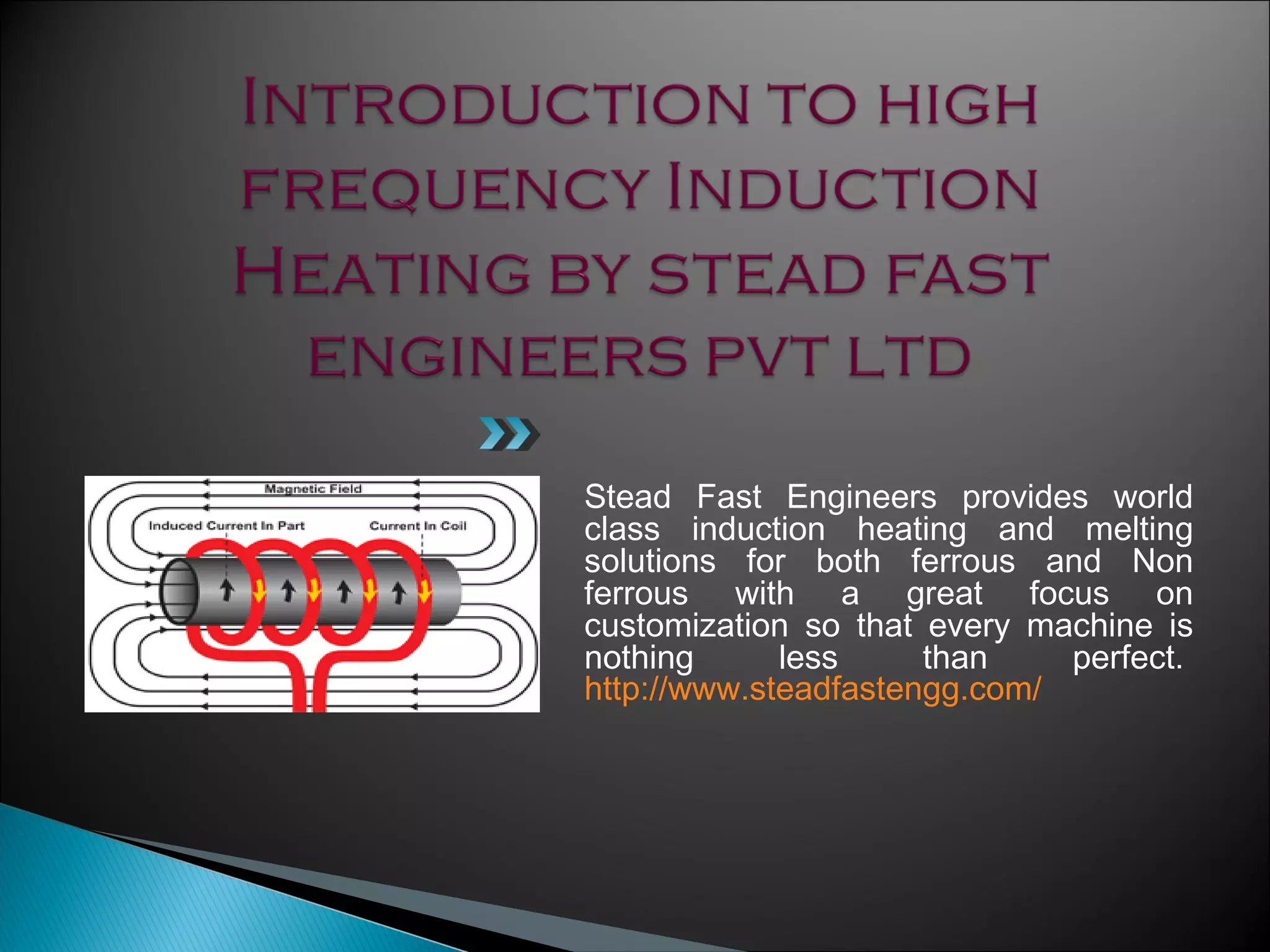

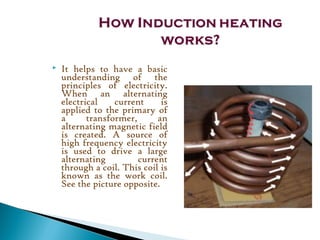

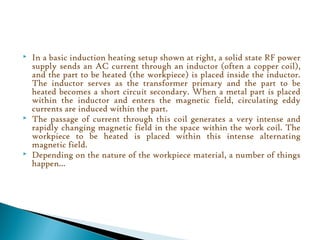

Stead Fast Engineers specializes in customized induction heating and melting solutions for both ferrous and non-ferrous materials, focusing on efficiency and precision. Induction heating is a non-contact process that generates heat within the workpiece, making it advantageous for modern manufacturing. The document also highlights the experience of Shapet Electric Company in producing various induction machines and their long-standing partnership with Tata Tanishq.