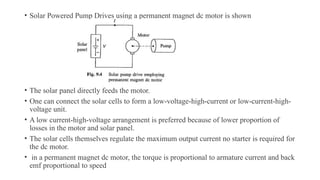

Essentially, solar-powered water pumps work by converting the sun's rays (photons) to electricity that will operate the water pump. It uses solar panels to collect the photons (units of light) from sunlight, producing the direct current (DC) that provides the energy for the motor to pump water out from its source

olar pump drives, also known as solar variable frequency drives (VFDs) or solar pump controllers, are essential for running pumps with solar power without needing batteries, by varying the motor speed based on available solar power.

What are Solar Pump Drives?

Solar pump drives are specialized electronic devices that act as a bridge between solar panels and water pumps, enabling efficient and reliable operation of pumps using solar energy. They are designed to handle the variable nature of solar power output, ensuring the pump operates optimally and prevents damage from over- or under-powering.

How Solar Pump Drives Work

Solar Panel Output:

Solar panels convert sunlight into direct current (DC) electricity.

Variable Power:

The amount of power produced by solar panels varies depending on factors like sunlight intensity and cloud cover.

Pump Motor Compatibility:

Many water pumps, especially those used for irrigation or water supply, are designed to operate with alternating current (AC).

Conversion and Control:

Solar pump drives convert the DC power from the solar panels into AC power suitable for the pump motor.

Variable Frequency Drive (VFD):

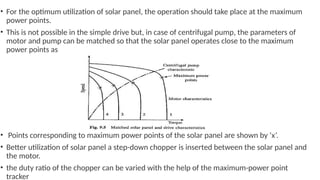

The drive acts as a VFD, meaning it can adjust the frequency and voltage of the AC power delivered to the pump motor.

Optimized Pump Operation:

By varying the motor speed based on the available solar power, the drive ensures the pump operates efficiently and prevents damage or premature wear.

No Batteries Required:

Unlike traditional solar-powered systems that rely on batteries, solar pump drives allow pumps to run directly from the solar array, eliminating the need for battery storage and associated costs and maintenance.

Water Storage:

Instead of storing electricity in batteries, the water is stored in a tank or pond, which is then used when needed.

Key Components of a Solar Pump Drive System

Solar Panels: The primary source of energy, converting sunlight into electricity.

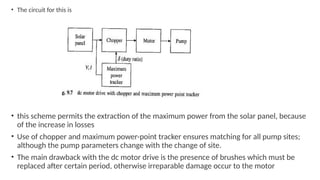

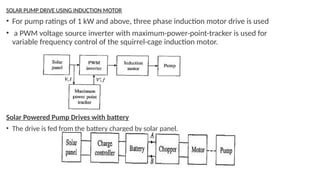

Solar Pump Drive (VFD): The heart of the system, converting DC power to AC power and controlling the pump motor speed.

Water Pump: A pump designed to lift water from a source (well, well, river, etc.).

Water Storage Tank/Pond: Stores the pumped water for later use.

Wiring and Connectors: Connect the components and ensure safe and reliable power transfer.

Optional: Sensors and Controllers: These can provide real-time data and control the system's operation.

Benefits of Using Solar Pump Drives

Cost-Effective: Eliminates the need for batteries, reducing initial and ongoing costs.

Reliable Operation: Ensures the pump operates efficiently and prevents damage from over- or under-powering.

Environmentally Friendly