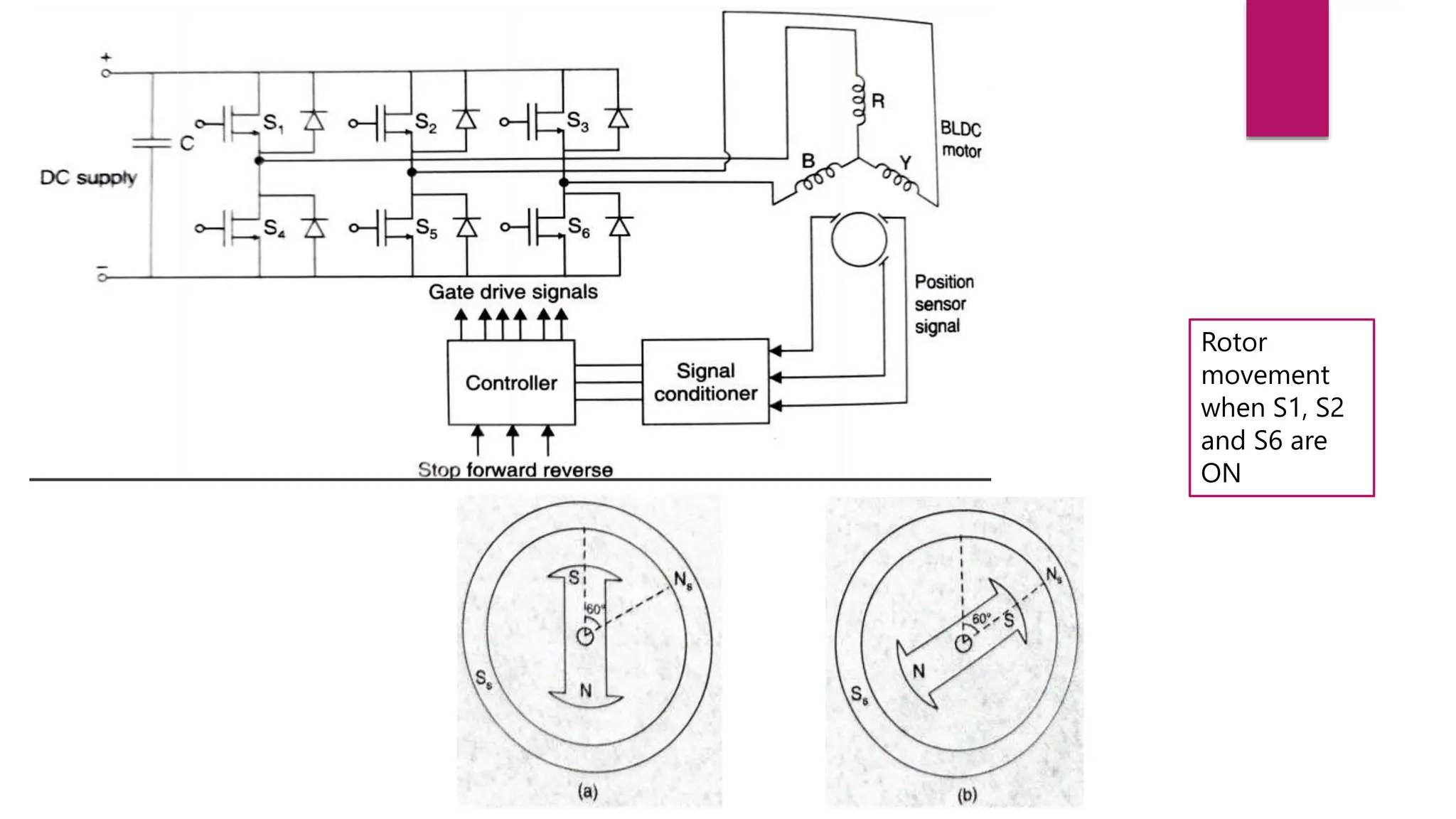

The document discusses DC motors and brushless DC motors for electric vehicle applications. It describes the types, construction, operation, and control of DC series motors and brushless DC motors. It also covers motor sizing considerations, regenerative braking, speed and torque characteristics, and thermal management of electric motors. Designing electric motors requires understanding the load and terrain conditions to size the motor and battery pack appropriately for the vehicle's intended usage.