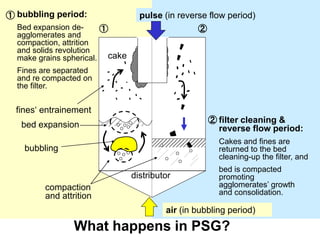

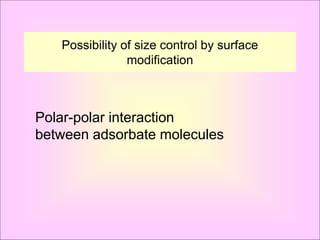

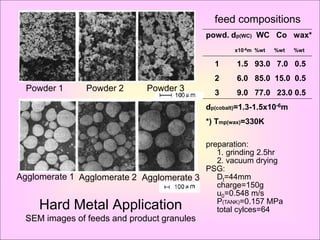

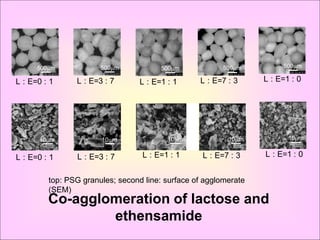

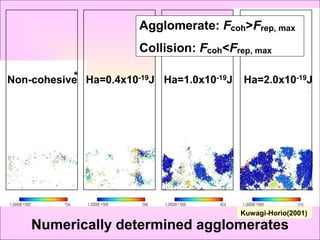

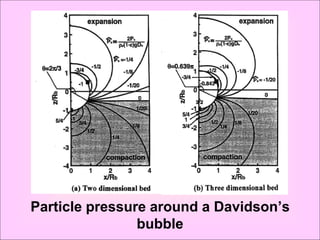

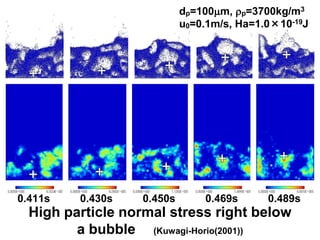

The document discusses binderless granulation and its potential, focusing on fundamental issues presented at the 7th International Symposium on Agglomeration. It details various experiments and findings related to pressure swing granulation, particle size distribution, and the effects of fluidizing gas velocity on agglomerate properties. The research indicates significant factors impacting granule density and suggests potential applications in the hard metal industry for improved material strength.

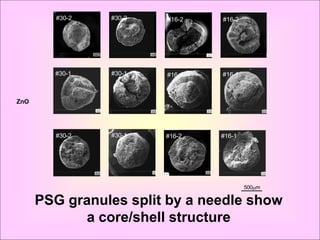

![①Fluidizing

Bag filter interval

15s

1s

②Compaction

interval

0 time[s] 7200

0.41m

f0.108m

Air ①Fluidizing ②Compaction

interval interval

(a) Test apparatus (b)Operation scheme

Pressure Swing Granulation

Nishii et al., U.S. Patent No. 5124100 (1992)

Nishii, Itoh, Kawakami,Horio, Powd. Tech., 74, 1 (1993)](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-3-320.jpg)

![Cumulative weight [%]

PSG

granules slide

from ZnO gate

dp=0.57m

after

1st fall

2nd fall

3rd fall

Particle size [10-6m]

PSG granules: weak but strong enough!

Change in PSD of PSG granules in realistic conditions](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-5-320.jpg)

![1000

Median diameter [m10-6]

500

E

150

0.1 0.5 1.0

Superficial gas velocity [m/s]

Effect of fluidizing gas velocity on da](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-10-320.jpg)

![1.2

Bulk density of granules [kg/m3]

w=0.4kg

1.0 0.2kg

with

gas velocity

0.8 and

solids charge

0.6

0 2.0 4.0 6.0

Maximum pressure difference for compaction [Pa104]

Factors affecting PSG granule density](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-11-320.jpg)

![500

Median diameter [10-6m] Median diameter [10- 600

Median diameter [10-

adsorption at: 293K, 293K,

p(adsorbate): 4kPa 4kPa

400 500

No effect: desorbed

during PSG

6m]

6m]

300 400

0 3 6 9 12 0 3 6 9 12 Notes: At 573K all

Absorption time [h] Absorption time [h] hydroxyl groups

Median diameter [10-6m]

500 on TiO2 are

500 eliminated

573K, 573K, (Morimoto, et al.,

13.3kPa 13.3kPa Bull. Chem. Soc.

400 JPN, 21, 41(1988).

400 Highest heat of

immersion at 573K

300 (Wade &

No effect ?? Hackerman, Adv.

Chem. Ser., 43, 222,

200 300 (1964))

0 3 6 9 12 0 3 6 9 12

Absorption time Absorption time [h]

[h] heat treatment:at p<13.3Pa

(a) C2H5OH (b) NH4OH 523K, for 6 hrs

adsorption:

bed= f150x10mm

Mean size of PSG granules from TiO2 (0.27x10 m) -6 in a 0.03m3 vacuum

dryer

after heat treatment and surface modification PSG: charge=0.0333 kg

u0=0.55 m/s RH: 40-

50%

Nishii & Horio (Fluidization VIII, 1996) fluidiz.:15 s comp.: 1 s

total cycles=450](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-13-320.jpg)

![Transverse rupture strength [N/mm2]

PSG

method

convent-

ional

method

Co content [wt%]

Application to hard metal industry

Improved strength of sintered bodies](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-15-320.jpg)

![1,000 0.1

500

Chaouki et al.

300

Iwadate-Horio 0.05

da [m] Bubble size

Da [m]

200 0.03

(IHM)

100 0.02

50 bubbling

Morooka et al. 0.01 fixed bed

30 bed

20 u0=umf

u0=0.5m/s

2,000

0.005

10 0.01 0.03 0.1 0.3 1 3

0.01 0.03 0.1 0.3 1 3 10 30 100 1,000

dp [m] 500

IHM

(a) Effect of primary particle size 200

da [m]

100

5,000 50

Chaouki et al.

2,000 Morooka et al.

20

1,000 IHM

da [m]

10

500 0.01 0.03 0.1 0.3 1 3

200 u [m/s]

0

100

50 Chaouki et al. (c) Effect of u0

20 Morooka et al.

u0=0.5m/s

10

0.3 0.5 1 2 3 5

Ha [J]

(b) Effect of Hamaker const.

Comparison of model performances](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-17-320.jpg)

![1.4E-3

1.2E-3

Lactose

1E-3 ZnO

da,calc [m] L:E=7:3

8E-4 L:E=1:1

L:E=3:7

6E-4

4E-4

2E-4

0E+0

0E+0 4E-4 8E-4 1.2E-3

2E-4 6E-4 1E-3 1.4E-3

da,obs[m]

Comparison of model predictions with observed data

Model (IHM) works !](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-18-320.jpg)

![Comparison of previous model concepts

Authors Model External force/energy Cohesion force/energy Comments

FGa Fpp

Chaouki

[ ]

FGa = Fpp No bubble

FGa = d a3

hwd p

hw

et al. Fpp =

2 1+ 8 2 3 hydrodynamic

ag

6 16

effects included.

Force balance Hr

van der Waals force

gravity force ≒drag force

between primary particles

No bubble

v=u mf Etotal =(Ekin+Elam ) Esplit

hydrodynamic

Etotal=(Ekin+Elam ) h w (1- a)d a2

Morooka Elaminer =3u mfd a2 Esplit =

effects included.

=Esplit shear

322 If 3 umf <hw (1-a)

et al. Ekinetic =mu mf 2/2 Etotal ad p /(32d p a),

Energy balance energy required to negative d a is

laminar shear + kinetic force

break an agglomerate obtained.

expansion Fcoh,rup

Fexp = Fcoh,rup exp = - Ps Bed expansion

force caused by

Db ag(-Ps)d a2 Had a(1- a)

bubble Fexp = Fcoh,rup = bubbles is

Iwadate-Horio 2n k 242 equated with

Force balance cohesive rupture

force.

bed expansion force cohesive rupture force](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-22-320.jpg)

![(a) example force balance and (b) Limiting size of agglomerates

two solutions

The critical condition

stable point unstable point

1E-4

1E-4

1E-5

^

Dbag(-Ps)d a2 B 1E-5

Fexp= 2nk

1E-6

A easy to 1E-6

C

log F[N]

log F[N]

1E-7

defluidize 1E-7

fluidized

1E-8 1E-8

saddle point

Hada(1- a)

Fcoh,rup=

1E-9 1E-9

24 2

1E-10

1E-10

1E-6 3E-6 1E-5 3E-5 1E-4 3E-4 1E-3 3E-3

1E-6 3E-6 1E-5 3E-5 1E-4 3E-4 1E-3 3E-3

log d a[m] log da[m]

Force balance of I-H model

and the critical solution](https://image.slidesharecdn.com/010529binderlessgranulationitspotentialandrelevantfundamentalissues7thisagglomeration-130303195408-phpapp02/85/010529-binderless-granulation-its-potential-and-relevant-fundamental-issues-7th-Intl-Symp-on-agglomeration-23-320.jpg)