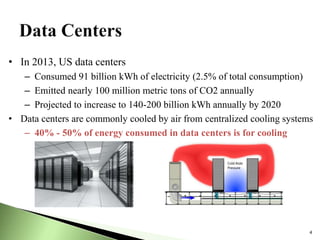

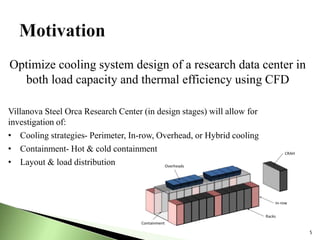

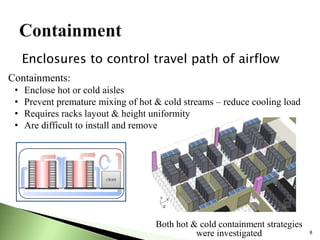

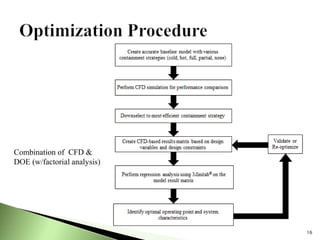

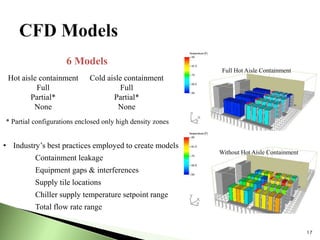

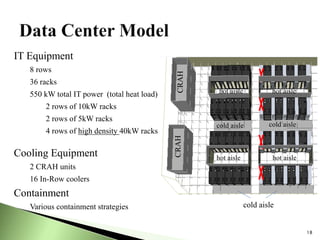

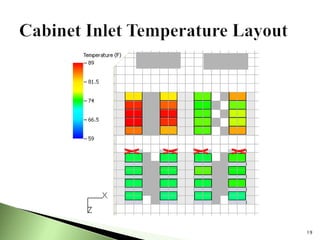

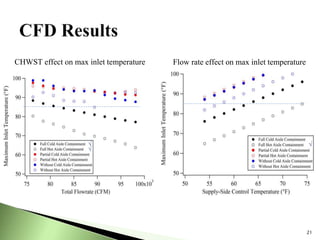

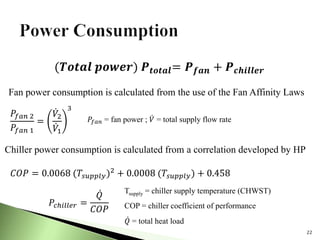

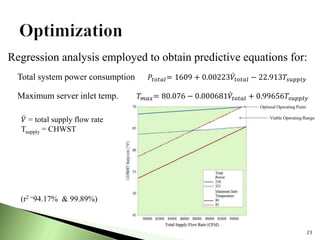

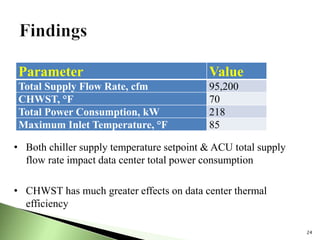

This document discusses research being conducted to optimize the cooling system design of the Villanova Steel Orca Research Center data center. Various cooling strategies and containment configurations will be tested using CFD software to minimize total energy consumption for cooling. Key factors like supply air flow rate and chiller supply temperature setpoint will be optimized. The most efficient designs will be validated at the new research facility to improve data center energy efficiency.