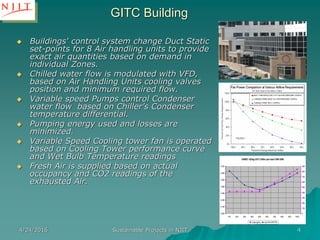

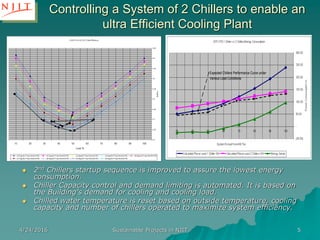

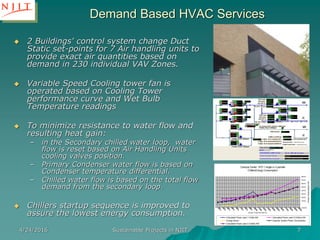

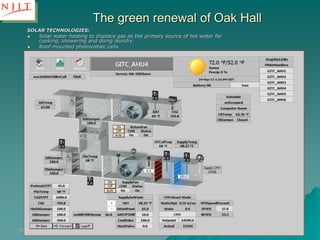

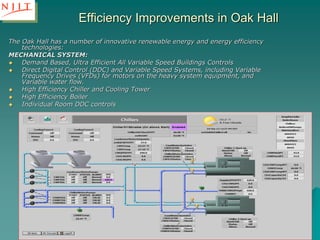

The document discusses several sustainable energy projects at NJIT, including upgrades to the campus-wide control system involving demand-based HVAC, lighting, and building controls. Specific buildings mentioned include the Campus Center, Fenster Hall, GITC, Oak Hall, and Weston Hall. Features described include variable speed pumping and cooling, chilled water reset, and heat recovery systems. Performance data and energy savings from the projects are presented.