The document contains lecture notes on hydraulics from Minia University in Egypt. It defines key terms related to fluid mechanics such as density, viscosity, laminar and turbulent flow, compressibility, and surface tension. It also provides the continuity equation and defines different types of fluid flow such as steady, uniform, rotational, and one, two, and three-dimensional flow. The notes conclude by listing the Bernoulli equation and its assumptions.

![Minia University Faculty of Engineering- Civil Eng. Dept. Hydraulics“HYD 313”

Page

20

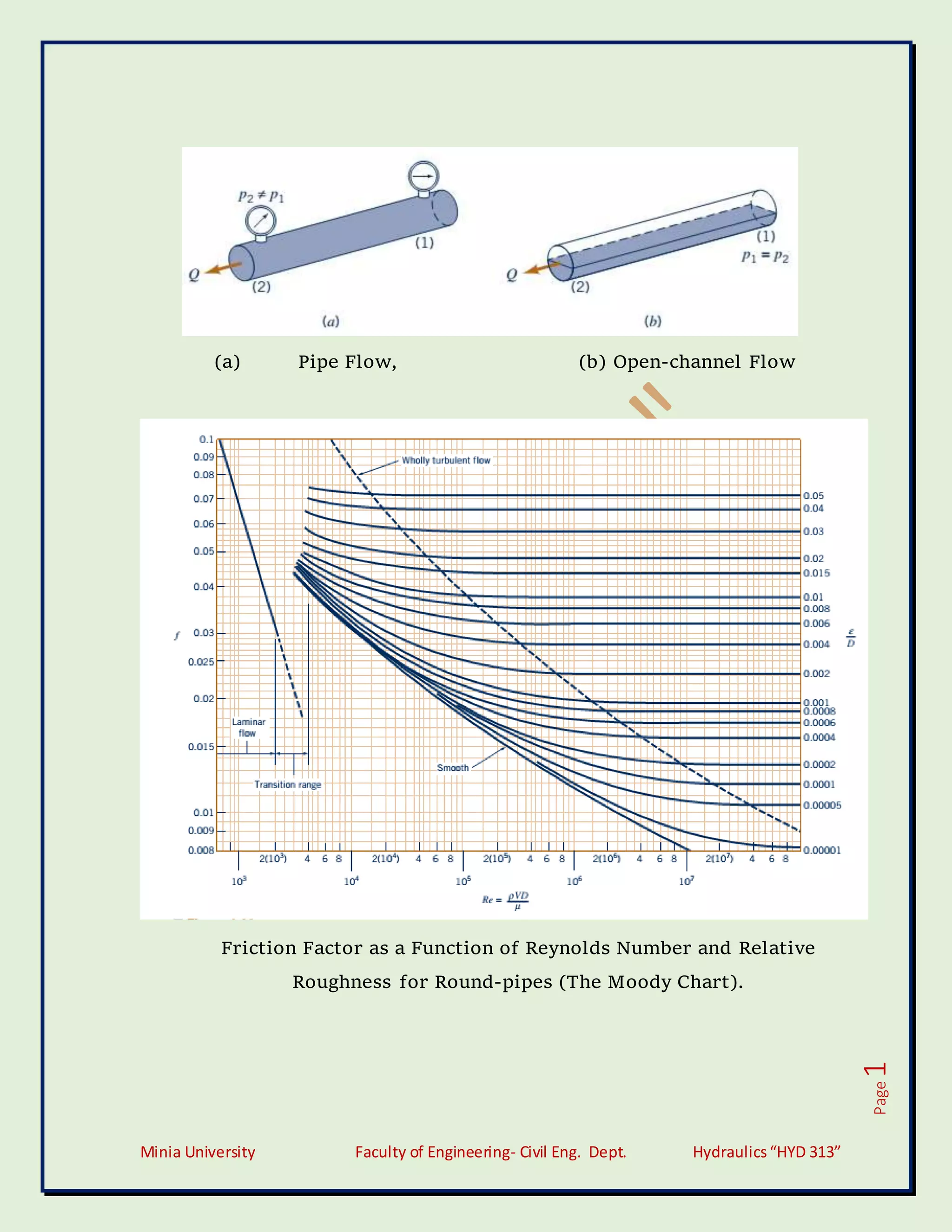

Moody’s diagram is accurate to about 15% for design calculations

and used for a large number of applications. It can be used for non-

circular conduits and also for open channels.

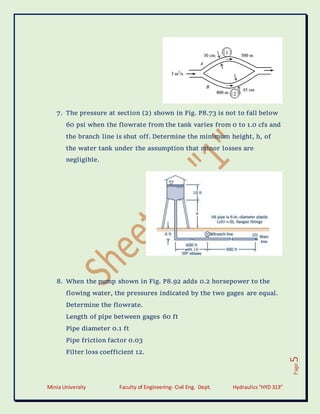

Define the terms:

a) Hydraulic gradient line [HGL]

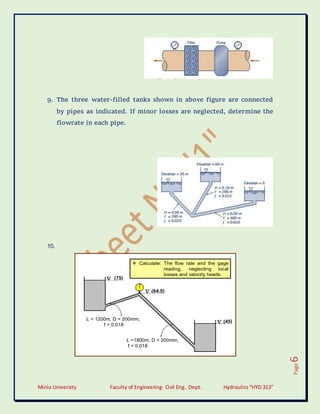

b) Total Energy line [TEL]

Hydraulic gradient line: It is defined as the line which gives the sum

of pressure head and datum head of a flowing fluid in a pipe with

respect the reference line.

HGL = Sum of Pressure Head and Datum head

Total energy line: Total energy line is defined as the line which gives

the sum of pressure head, datum head and kinetic head of a flowing

fluid in a pipe with respect to some reference line.

TEL = Sum of Pressure Head, Datum head and Velocity head

T.E.L = Sum H.G.L + Velocity head

Write the dimensions for the followings.](https://image.slidesharecdn.com/sheetofpipeflow-220921150148-07fa9136/85/sheet-of-pipe-flow-20-320.jpg)