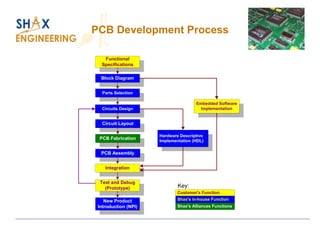

This document provides an overview of an engineering and manufacturing company that offers end-to-end PCB design and manufacturing services. The company was established in 1998 to assist with electronic product development and provides integrated circuit design, PCB layout, fabrication, assembly, testing, and other manufacturing services. Outsourcing to the company benefits clients by freeing up resources, reducing costs, shortening time to market, and reducing risks. The company prides itself on over 80 years of combined technical expertise, a 95% client reorder rate, and establishing true partnerships with clients.