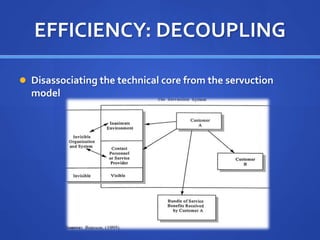

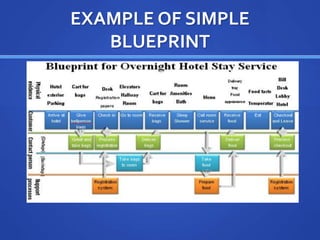

This document discusses service delivery processes and how to improve efficiency. It covers balancing customer contact with operational efficiency. Firms must balance demand cycles and the length of customer experiences. Applying concepts like Thompson's perfect world model, focused factories, and plant-within-a-plant can help isolate technical cores and minimize customer interactions to improve efficiency. Blueprinting maps out service processes to identify bottlenecks and opportunities to streamline flow and reduce costs and wait times. The goal is to understand unique aspects of service delivery and improve customer involvement and operational performance.