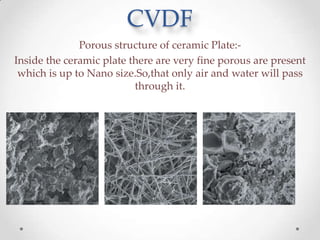

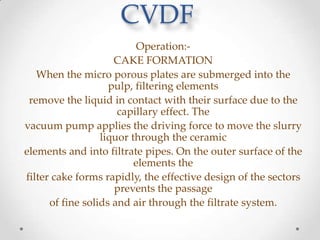

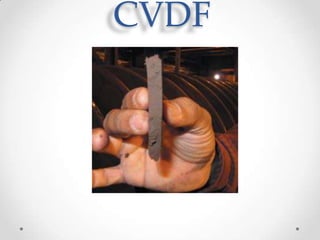

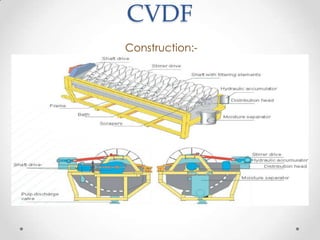

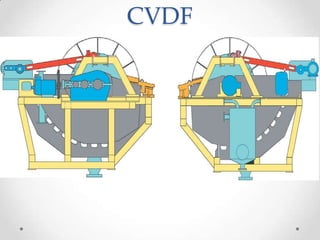

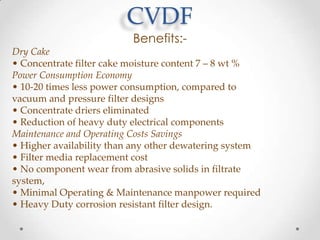

This document summarizes a seminar presentation on ceramic vacuum disc filters (CVDF). CVDF is a new filtration technique used to separate minerals from high solids concentration slurries in mining and mineral beneficiation industries. It utilizes ceramic discs with nano-sized porous structures and vacuum pressure to form and dewater filter cakes with moisture contents as low as 7-8%. CVDF provides benefits over traditional filters such as lower maintenance costs, continuous operation, clear filtrate, and improved safety.