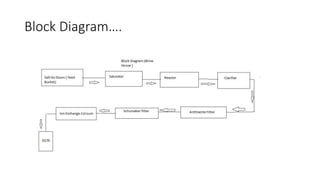

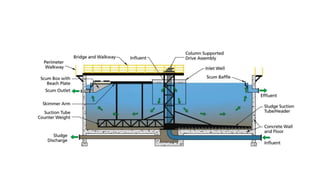

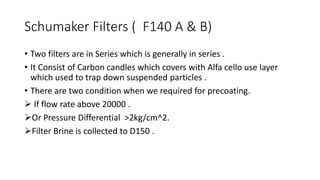

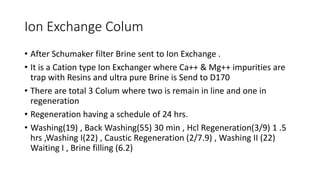

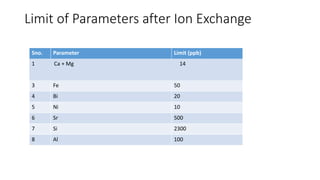

The brine house section purifies salt through primary and secondary processes. In primary filtration, return brine is saturated with salt and impurities are removed through reactors, clarifiers, and anthracite filters. Secondary filtration further purifies the brine through brine filters and ion exchange resin columns. The purified brine is then stored in tanks with ion levels below specified limits before use or distribution.