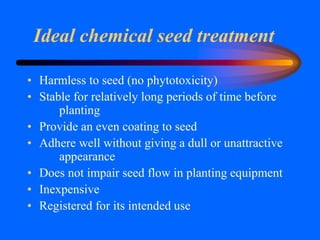

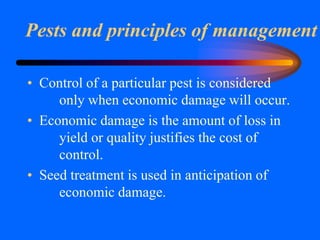

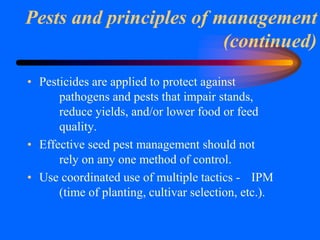

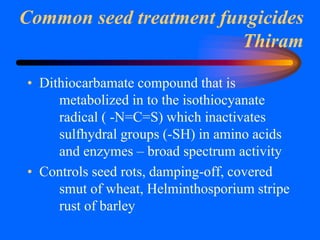

Seed can harbor pathogens and soil contains organisms that attack seeds and seedlings. Treating seed with pesticides can improve stand quality, increase yields, and increase return on investment. It involves applying a pesticide to seeds to reduce disease organisms, insects, or other pests that attack seeds or seedlings during storage and after planting. Common seeds treated are corn, small grains, cotton, forage grasses, sorghum, soybeans and vegetables. Seed treatment involves properly applying precisely measured pesticide quantities to seeds using equipment that mixes the pesticide and gently coats the seeds uniformly.