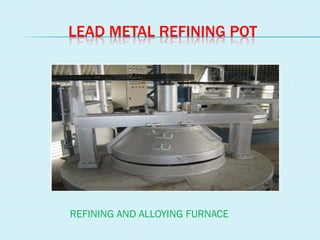

This document contains a profile for B.K. Ghaaty, who has over 20 years of experience in non-ferrous metal project design, fabrication, and installation. It lists 3 lead recycling plants that Ghaaty has worked on in India with processing capacities ranging from 3000-7000 metric tons per month. It also mentions supplying a plant to Metenere Limited in Dubai. The document provides details on lead recovery from battery recycling and the processes involved, including automatic battery breaking, smelting, refining, and production of lead oxides. It emphasizes Ghaaty's expertise in setting up full lead recycling plants.