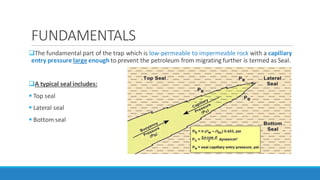

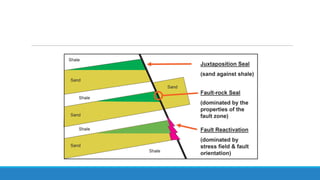

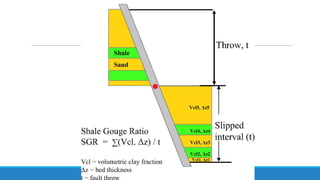

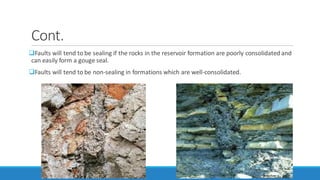

Seal rocks are essential for trapping hydrocarbons, characterized by low permeability and sufficient capillary entry pressure. Common types of seals include membrane and hydraulic seals, and their effectiveness is evaluated through methods like fault seal analysis and fold seal analysis. Factors influencing seal quality include rock properties, thickness, and the balance between buoyancy forces and capillary pressures.