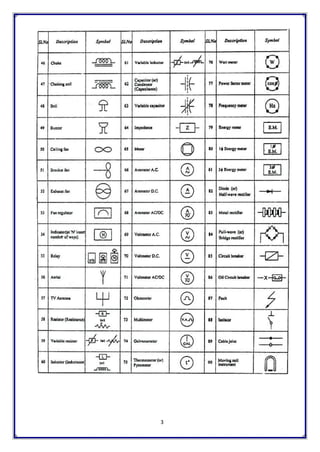

Electric fires can be caused by short circuits, overloading, poor insulation, or lightning. Fires are classified based on the type of fuel source - Class A for solids, Class B for liquids, Class C for gases, and Class D for metals. The right type of fire extinguisher must be used for each class of fire, such as dry chemical powder or CO2 extinguishers for electrical fires, in order to effectively put out the fire.

![18

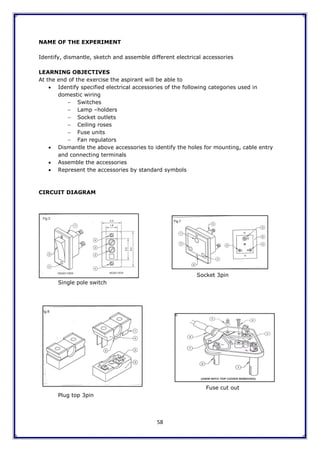

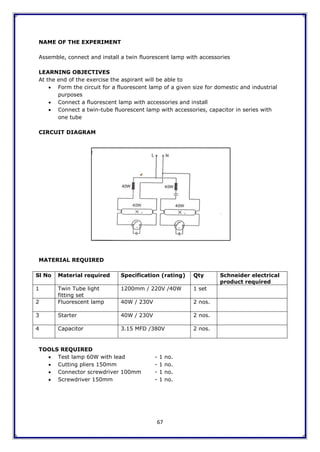

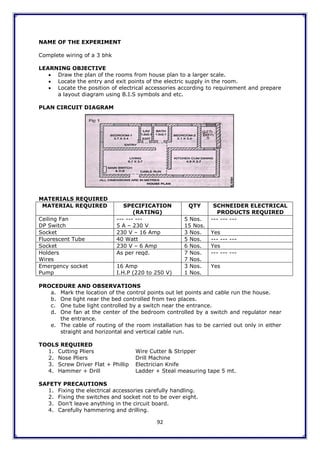

CHAPTER VII: ELECTRICAL ACCESSORIES

Switches, Sockets

Introduction

Electrical appliances occupy a prime place of importance in our life style. The usage of

electricity in modern life is increasing the standard of living in almost every home. On the

other hand, Electrical wiring, which is essential for these appliances to work, receives very

little attention. As an electrical technician, contractor, consultant or architect we are

responsible to both the builder and consumer. The reputation and success of technicians

depends on the quality of wiring they door recommend.

Teaching and Learning Methodology

Lecture Method, Demonstration and Site visit

Aim

To impart knowledge and related skills to the aspirant

Learning Objective

At the end of this session the aspirant will know about the:

a. Protection and distribution of supply system and accessories used

b. Cable carrier and support system

c. Different types of current carrying conductors

d. Switching and terminating products

e. Sensor switching etc.

Preview

House wiring accessories can be classified into the following

categories:

a. Control and distribution system

b. Cable carrier and support system

c. Current carrying conductors (wires)

d. Switching and termination products

e. Sensor Switches

a. Control (Protection) and distribution system

This system is used to control the main supply and distribute it to the circuits. The main

protective devices used in house wiring circuits are:

i. Fuses (Fuse that can be re-wired, HRC Fuses available at diff

ranges [6Amp to 200Amp])

ii. ICDP, ICTP (available at 32A to 200A)

iii. Miniature Circuit Breakers (available at 1A to 40A)

iv. Isolator (available at 32A to 63A)

v. ELCB / RCCB – (available at 32A, 40A & 63A) and MCCB above

63A

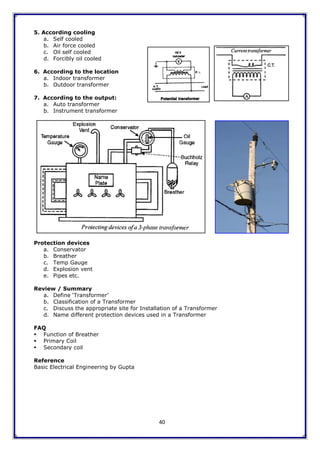

All the above mentioned items are installed in control and distribution

boards. The Boards are available in 1 phase, 3 phase, single door and

double door as shown in the picture.

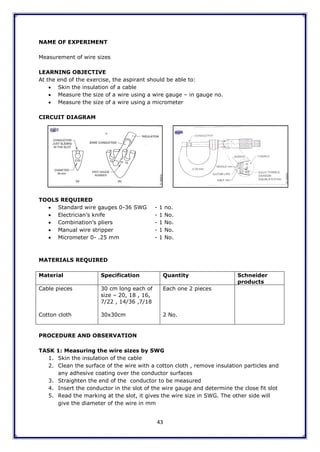

b. Cable carrier and support

The house wiring cable can‟t be run or laid on walls without support.

Hence the wires need to be supported from the main distribution till

the terminating product. The systems used to carry, support and run

these wires are called cable carriers and support systems. The different

systems which we adopt for the same are as follows:

i. Wooden capping & casing wiring](https://image.slidesharecdn.com/schneiderelectricalhandbook-210216112928/85/Schneider-electrical-handbook-24-320.jpg)

![37

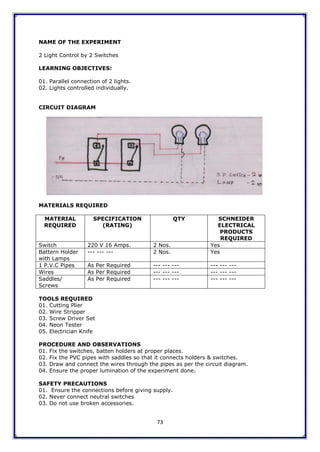

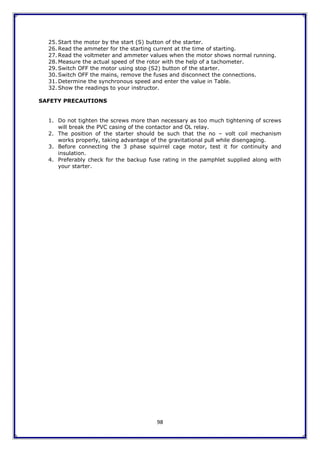

ii. Semi Automatic delta starter

iii. Fully automatic delta starter

3. Auto: Transformer type starter

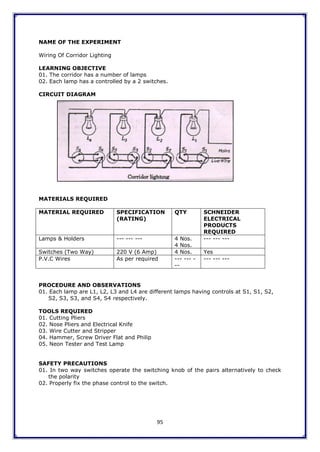

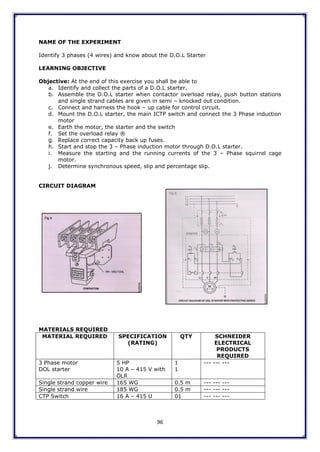

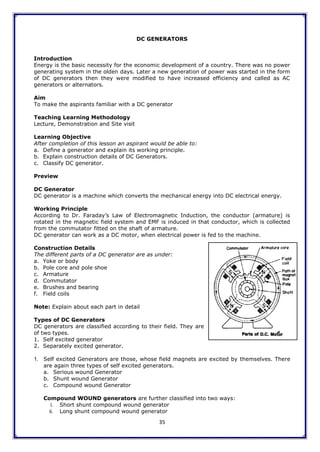

1. Direct Online (DOL) Starter

It is a simple and ordinary starter, suitable for squirrel cage induction motors that have a

capacity up to 5 HP. It does not reduce the voltage. It is sufficient to connect the motor from

the line ICTP / Main switch / Isolator. The DOL starter has the following advantages:

a. The motor can be switched on and off quickly.

b. It cuts the motor from the line one over loads.

c. It prevents the motor from burning on single phase.

Mainly DOL starters consist of contact system thermal relay units and a solenoid coils.

The contact system consists of silver tipped contacts, which provides a quick on – off

system.

Thermal relay bimetallic elements protect the motor from over load.

The solenoid coil or no–volt coil is connected across the two phases. (Phase and

neutral in case of single phase)

On pressing the start button the solenoid coil becomes magnetized and it attracts the

iron, plunger, which closes all the contact points.

In this way L1, L2 and L3 are connected to the motor terminals M1, M2 and M3 and

the motor starts running, as shown in the picture above.

Push buttons are used in place of the handles. The green push button starts the motor, while

the red push button switches off the motor. A latch fitted near the red push button can be

adjusted over it, so that motor may not be started.

Protective Devices

No–Volt Coil (NVC) and Over Load coil Relay (OLR) are provided in a start delta starter as

protective devices.

No–Volt Coil (NVC) [Ref Figure given below]

It is an electromagnetic coil made of fine copper wire. The NVC is connected to B2 and A2

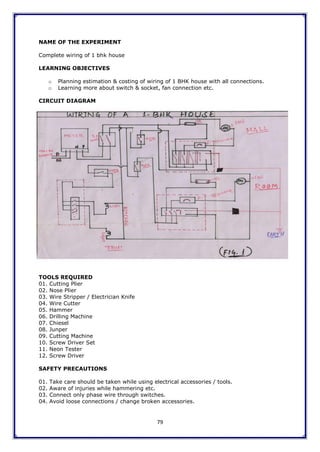

terminals. These terminals get supply from L1 to L3 respectively in the run position. If the

supply fails, the motor becomes over loaded, then the NVC will be demagnetized and will

release the handle, thus the motor will be switched off.

Over–Load Relay

It consists of three bi-metallic strips, which get bent in one direction, above a pre-set

temperature. The bending of these strips disconnects the NVC, which will leave the hands of](https://image.slidesharecdn.com/schneiderelectricalhandbook-210216112928/85/Schneider-electrical-handbook-43-320.jpg)