The document is a training module titled 'Using Basic Electronic Hand Tools' designed for the Consumer Electronic Servicing NC II program in the Philippines. It outlines learning outcomes for identifying, using, and maintaining basic electronic hand tools, along with various activities and assessment methods. The module includes technical terms, learning activities, and a structured approach to gain competency in using hand tools effectively and safely.

![32

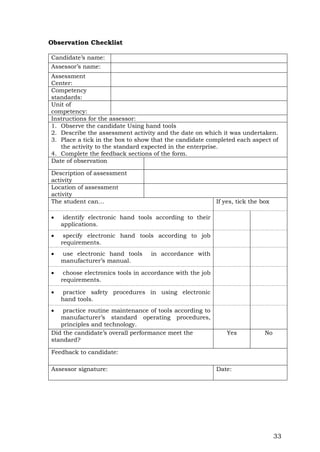

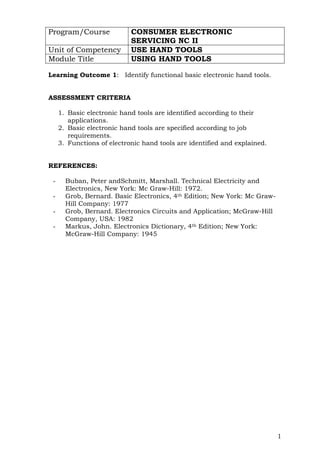

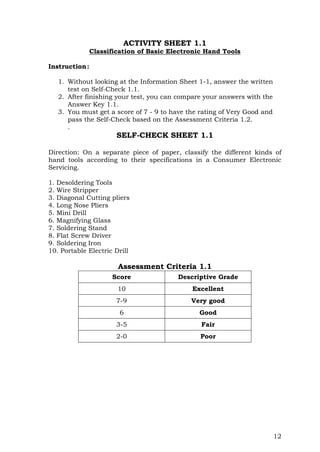

ASSESSMENT PLAN

Evidence Checklist

Competency standard: Consumer Electronic Servicing NC II

Unit of competency: Use Basic Electronic Hand Tools

Title of Module Using Basic Electronics Hand Tools

Ways in which evidence will be collected:

[tick the column]

Observation

Questioning

Third

party

Report

Demonstration

Portfolio

Written

The evidence must show that the student can…

identify the basic electronic hand tools in

accordance with their applications.

Specify electronic hand tools according

to job requirements.

Identify functions of electronic hand tools.

choose electronic hand tools in

accordance with the job requirements.

use electronic hand tools in accordance

with the manufacturer’s manual.

practice safety procedures in using

electronic hand tools.

report defective electronic hand tools to

appropriate personnel.

practice routine maintenance of electronic

hand tools according to manufacturer’s

standard operating procedures, principles

and techniques.

keep safely electronic hand tools in a

designated location per manufacturer’s

specifications or standard operating

procedure.

Prepared

by:

Date:

Checked

by:

Date:](https://image.slidesharecdn.com/y2-module1-usingbasicelectronichandtools-221102134351-232b2cb0/85/TLE-CES-NC-II-Y2-Module-1-Using-Basic-Electronic-Hand-Tools-doc-39-320.jpg)