Recommended

PDF

MITSUBISHI_CR750CR751-Controller-Instruction-Manual-Detailed-Explanations-of-...

PDF

Rv1 a2aj instruction manual.bfp-a8052e

PDF

C rn melfa basic.bfp-a5992_p

PDF

C rn troubleshooting(bfp-a5993_m)

PPTX

PDF

PDF

Necessities in Robotic Safety Systems

PPTX

VIRA_Basics_of_Robot_Level_1.pptx

PDF

PPTX

DFP.IOS-SAFETY-DDEVELOP.AKSPDLSLMALK.pptx

PDF

Cr1.cr1 b instruction manual(bfp-a8054j)

PPT

PPTX

PDF

Catalog biến tần Inovance MD290 - HPC

PDF

Rv1 a.2aj specs.bfp a8050k

PPTX

PPT

PPSX

Robots one day presentation

PPTX

ROBOT HAZARD AND PREVENTION

PPTX

Chapter 1 Intro to industrial robot automation (2)

PDF

PPTX

Robotics is the interdisciplinary branch.pptx

PDF

Industrial Robotics in manufacturing industry

PPTX

PPT

Industrial Automated Robots Working and explanation

PPTX

VALERI_EventoRoboticaUNI_UCIMU_SIRI_4luglio2025.pptx

PDF

PPT

06._industrial_robotics_.ppt_.vikramsingh

PPTX

Unit I – Introduction to Devops�Deployment Pipeline & Design Options Deploym...

PPTX

CFP_Unit 4. Arrays, Structure and Pointers pptx

More Related Content

PDF

MITSUBISHI_CR750CR751-Controller-Instruction-Manual-Detailed-Explanations-of-...

PDF

Rv1 a2aj instruction manual.bfp-a8052e

PDF

C rn melfa basic.bfp-a5992_p

PDF

C rn troubleshooting(bfp-a5993_m)

PPTX

PDF

PDF

Necessities in Robotic Safety Systems

PPTX

VIRA_Basics_of_Robot_Level_1.pptx

Similar to IRC5 Basic Operations Revision d_5.pptx

PDF

PPTX

DFP.IOS-SAFETY-DDEVELOP.AKSPDLSLMALK.pptx

PDF

Cr1.cr1 b instruction manual(bfp-a8054j)

PPT

PPTX

PDF

Catalog biến tần Inovance MD290 - HPC

PDF

Rv1 a.2aj specs.bfp a8050k

PPTX

PPT

PPSX

Robots one day presentation

PPTX

ROBOT HAZARD AND PREVENTION

PPTX

Chapter 1 Intro to industrial robot automation (2)

PDF

PPTX

Robotics is the interdisciplinary branch.pptx

PDF

Industrial Robotics in manufacturing industry

PPTX

PPT

Industrial Automated Robots Working and explanation

PPTX

VALERI_EventoRoboticaUNI_UCIMU_SIRI_4luglio2025.pptx

PDF

PPT

06._industrial_robotics_.ppt_.vikramsingh

Recently uploaded

PPTX

Unit I – Introduction to Devops�Deployment Pipeline & Design Options Deploym...

PPTX

CFP_Unit 4. Arrays, Structure and Pointers pptx

PPTX

70,000 RPM Aerospace Bearing Testing – Why High-Speed Validation Is Critical

PPTX

Why Hydraulic Flushing Should Never Be Skipped Before Commissioning

PDF

UNIT02_TRE_GEOMETRIC DESIGN.pdf_________

PPTX

Power Electronics_PE_lecture_10_presentation .pptx

PDF

Flexibility Matrix Method of Analysis- Part B

PDF

Stiffness Matrix Method of Analysis for beams and frames

PDF

Branches of AI – perception, reasoning, learning, and action.pdf

PPT

OMRS for Railway people of Mechanical department

PDF

lecture notes digital_design_examples.pdf

PPTX

Why Precision Matters CO2 N2 Gas Filling Systems Neometrix

PPTX

Atlassian for the New Age: Efficiency, Alignment & Collaboration at Scale

PPTX

1.1 Structure of Materials_Material science.pptx

PPTX

High Voltage Direct Current Circuit Breakers.pptx

PDF

graph graph graph theory Graph presentation .pdf

PPTX

review of transistor circuit and applications

PPTX

Design and Development of Friction Stir Welding joints of Aluminium and Coppe...

PPTX

analog communication part one lecture note

PPTX

Ortho Graphic Projections for civil engineering.pptx

IRC5 Basic Operations Revision d_5.pptx 1. 2. Regulation and Safety in ABB Malaysia

Before entering our factory area, please ensure that you are

briefed by your ABB host on the basic safety & health rules

All visitors and guests must be accompanied by ABB employees

while on a factory tour or testing

Please ensure that your Visitor Pass is prominently displayed at all

times

Safety shoes must be worn at the factory area unless you are in

the green zone

Use of mobile phone is strictly prohibited when you are engaged in

critical tasks such as testing

Do not stand or cross underneath the overhead crane while it is in

operation

Do not smoke within the factory and warehouse area. Smoking is

allowed at designated smoking areas only

© ABB Robotic May 8, 2017

3. Regulation and Safety in ABB Malaysia

For your safety, please do not tamper with any electrical

equipment

Visitors who are under the influence of drugs or alcohol are

advised against entering the company’s premises

Do not enter a “live” installation testing area without prior

authorization

Please ensure that you have been briefed on ABB’s emergency

and evacuation plan

Please exercise caution at blind corners

Always observe and follow the traffic signs

Please do not operate any equipment without the authorization

ABB personnel

Report all incidents, near misses, unsafe acts and unsafe

condition to your ABB host

© ABB Robotic May 8, 2017

4. 5. Emergency procedure

Upon hearing the first alarm - stop work or discussion

Once you hear the second emergency alarm – follow your

ABB host to evacuate the building

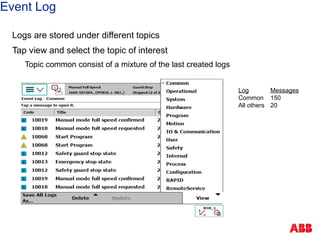

Use the nearest exit

Do not run or panic

Use the staircase. Do not use the lift during an emergency

Proceed to the emergency assembly area

At the assembly area, please follow instructions of ABB

personnel in-charge

All clear signal – please wait for the all clear signal before

re-entering the building

Please dial 4816

for all

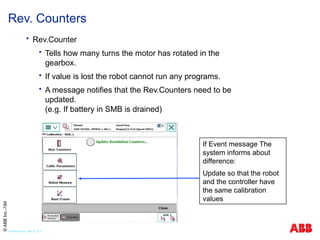

emergencies

© ABB Robotic May 8, 2017

6. 7. Course Content

Section Description

1 Introduction

2 Safety

3 System Description

4 Getting Start

5 Jogging & Coordinate System

6 IO Signal

7 Handling Programming

9 Backup and Restore

10 Event Massage

11 Restarts

12 Calibration

© ABB Robotic May 8, 2017

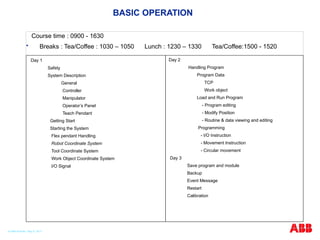

8. BASIC OPERATION

Course time : 0900 - 1630

Breaks : Tea/Coffee : 1030 – 1050 Lunch : 1230 – 1330 Tea/Coffee:1500 - 1520

Day 1

Safety

System Description

General

Controller

Manipulator

Operator’s Panel

Teach Pendant

Getting Start

Starting the System

Flex pendant Handling

Robot Coordinate System

Tool Coordinate System

Work Object Coordinate System

I/O Signal

Day 2

Handling Program

Program Data

TCP

Work object

Load and Run Program

- Program editing

- Modify Position

- Routine & data viewing and editing

Programming

- I/O Instruction

- Movement Instruction

- Circular movement

Day 3

Save program and module

Backup

Event Message

Restart

Calibration

© ABB Robotic May 8, 2017

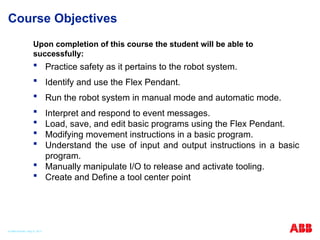

9. Course Objectives

Practice safety as it pertains to the robot system.

Identify and use the Flex Pendant.

Run the robot system in manual mode and automatic mode.

Interpret and respond to event messages.

Load, save, and edit basic programs using the Flex Pendant.

Modifying movement instructions in a basic program.

Understand the use of input and output instructions in a basic

program.

Manually manipulate I/O to release and activate tooling.

Create and Define a tool center point

Upon completion of this course the student will be able to

successfully:

© ABB Robotic May 8, 2017

10. Course Objectives

Use movement instructions in a basic program..

Create routines, and use routine instructions in a basic

program..

Understand and update Revolution Counters.

Upon completion of this course the student will be able to

successfully:

© ABB Robotic May 8, 2017

11. 12. © ABB Robotic May 8, 2017

Robot Safety during training course

Keep fingers clear of gripper jaws when loading parts

Stand clear of robot benches when running programs

Test all program modifications in a manual mode first

Full speed modes are permitted with instructors assistance

Be cautious when releasing brakes

When inside the robot cell, make sure you have control of Pendant

13. Safety Solutions – an Overview

Pinch Points

Lock Outs

Emergency stop

Operating mode

Auto

Manual < 250 mm/s

Manual 100% (Option)

Enabling device

(Dead mans grip)

Hold-to-run

Safeguard stop

(Auto and Manual)

Limiting the workspace

Enabling device

Hold-to-run buttons

(for left or right hand)

14. Pinch Point

© ABB Robotic May 8, 2017

Evaluate the machine and its movement to identify and avoid pinch points

Pinch points are any

areas where you can

get caught between

the moving parts of a

robot and stationary

object.

Physical guards

create a barrier to

prevent you from

getting trapped or

injured in pinch point

15. LOCK OUT/TAG OUT

© ABB Robotic May 8, 2017

Proper Lock Out /Tag Out practices and procedures safeguard yourself and

other from release hazardous energy. To lock out turn the key switch to

Manual Mode, then turn the rotary disconnect to the Off position. Open

the locking mechanism on the disconnect & place your lock or a multiple

“gang lock” device on the disconnect.

16. LOCK OUT /TAG OUT (LOTO)

OBJECTIVE

Preventing the unexpected start up or release of stored energy from equipment

during maintenance and repairs to protect employees from injury

To prevent equipment from unexpectedly being set in motion and endangering

workers.

Potential hazardous energy sources must be identified ,isolated and locked

and tagged out before starting a service/ maintenance tasks

© ABB Robotic May 8, 2017

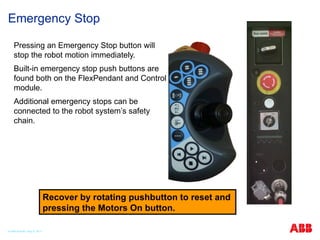

17. Emergency Stop

Pressing an Emergency Stop button will

stop the robot motion immediately.

Built-in emergency stop push buttons are

found both on the FlexPendant and Control

module.

Additional emergency stops can be

connected to the robot system’s safety

chain.

Recover by rotating pushbutton to reset and

pressing the Motors On button.

© ABB Robotic May 8, 2017

18. Operating Mode

Automatic mode

Production mode (no speed limit)

Manual mode

< 250 mm/s – max velocity 250 mm/s

100 % – Option, robot can be jogged/tested

with no speed limit.

19. © ABB Robotic May 8, 2017

Manual Full Speed (Optional)

Press and Hold down the play key, to run the program

Press and Hold down the FWD or BWD key to step

Releasing the pressed key to stops execution

1

2

20. © ABB Robotic May 8, 2017

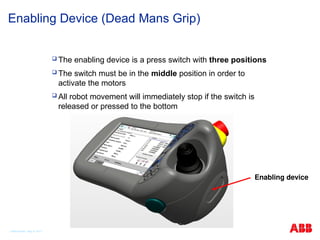

Enabling Device (Dead Mans Grip)

The enabling device is a press switch with three positions

The switch must be in the middle position in order to

activate the motors

All robot movement will immediately stop if the switch is

released or pressed to the bottom

Enabling device

21. © ABB Robotic May 8, 2017

Safeguard Stops

Your robot system can be equipped with a vast range of safeguards such as

door interlocks, safety light curtains, laser scanners and pressure mats etc.

A safeguard prevents hazardous situations by stopping the manipulator in a

controlled manner when a mechanism such as a light curtain is activated

The controller has three separate safeguarding mechanisms,

General stop (GS) Always active regardless of operating mode

Automatic stop (AS) Only active in auto mode

Superior stop (SS). Always active regardless of operating mode

22. Limiting the Workspace

To avoid the risk of getting caught between

the robot and the perimeter safety

equipment, e.g. a fence, the robot’s

workspace can be limited:

All axis can be software limited

On some robots Axis 1–3 can be limited

by adjustable mechanical stops and

controlled by limit switches

23. Working range of robot axis

All Axis are software controlled to limit their rotational range

The software stop should prevent collision at the end of axis

rotational travel

Axis 1–3 can on larger robots, can be fitted with adjustable

mechanical stops

Training robots axis are set to the default maximum range

© ABB Robotic May 8, 2017

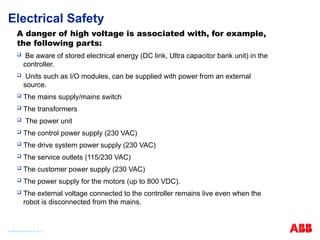

24. Electrical Safety

A danger of high voltage is associated with, for example,

the following parts:

Be aware of stored electrical energy (DC link, Ultra capacitor bank unit) in the

controller.

Units such as I/O modules, can be supplied with power from an external

source.

The mains supply/mains switch

The transformers

The power unit

The control power supply (230 VAC)

The drive system power supply (230 VAC)

The service outlets (115/230 VAC)

The customer power supply (230 VAC)

The power supply for the motors (up to 800 VDC).

The external voltage connected to the controller remains live even when the

robot is disconnected from the mains.

© ABB Robotic May 8, 2017

25. © ABB Robotic May 8, 2017

Brakes Release

The brakes on the robot motors can be manually released

Make sure the weight of the robot axis and tooling are supported

Brakes are reapplied when button is released

IRC5C controller

brake release button

26. © ABB Robotic May 8, 2017

Safety Regarding Grip Device

All grip devices must be designed so the work piece will be held even on

power failure and other disturbances in the robot system

There should be possibilities to loosen the work piece manually

Familiarize yourself with operational buttons assigned to the gripper function

27. Personal Safety

Principles should be followed in order to operate the

robot system safely:

Always operate the robot system in manual mode if personnel are inside

safeguarded space.

Always bring the Flex Pendant along when you enter safeguarded space so

that robot control is in your hands.

Watch out for rotating or moving tools such as milling cutters and saws.

Make sure those are stopped before you approach the robot.

Watch out for hot surfaces both on work pieces as well as on the robot

system. The robot's motors can become fairly hot if run for a long time.

Watch out for grippers and objects gripped. If the gripper is opened the work

piece could fall and cause injuries or damage equipment. The gripper can be

very powerful and can also cause injuries if not operated in a safe manner.

Watch out for hydraulic and pneumatic systems and live electric parts. Even

with power off residual energy in such circuits can be very dangerous.

© ABB Robotic May 8, 2017

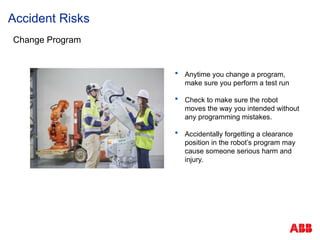

28. 29. Accident Risks

Fault tracing

Fault tracing and repair procedure

go hand in hand .you are at your

vulnerable when you’re fixing a

robot.

Never rush through the steps and try

to work around the safety

procedures .

30. Accident Risks

Change Program

A program change may mean what

was safe space yesterday isn’t a

safe space today

Be sure you are following procedure

and clear communicating

information about any program

changes

31. Accident Risks

Change Program

Anytime you change a program,

make sure you perform a test run

Check to make sure the robot

moves the way you intended without

any programming mistakes.

Accidentally forgetting a clearance

position in the robot’s program may

cause someone serious harm and

injury.

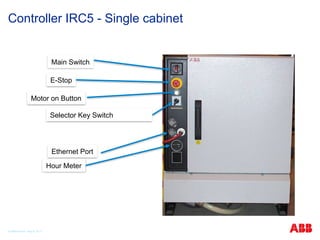

32. 33. 34. Controller IRC5 - Single cabinet

© ABB Robotic May 8, 2017

Main Switch

E-Stop

Motor on Button

Selector Key Switch

Ethernet Port

Hour Meter

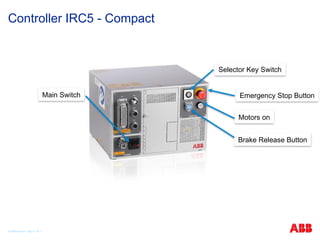

35. Controller IRC5 - Compact

© ABB Robotic May 8, 2017

Main Switch Emergency Stop Button

Motors on

Selector Key Switch

Brake Release Button

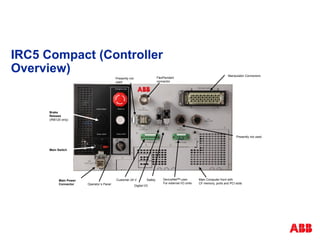

36. IRC5 Compact (Controller

Overview)

Main Power

Connector

Manipulator Connectors

Operator´s Panel Digital I/O

Safety

Presently not

used

FlexPendant

connector

Brake

Release

(IRB120 only)

Main Computer front with

CF memory, ports and PCI slots

DeviceNetTM

Lean

For external I/O units

Customer 24 V

Presently not used

Main Switch

37. IRC5 Single Cabinet (Controller Overview)

Main Computer

Unit

Field bus

adapter:

Ethernet

I/PTM

PROFIBUS

DP

PROFINET

IO

Compact Flash

mass memory

I/O units or PLC

Main Drive

Unit

Additional Drive

Unit

Front connectors

behind cover

UltraCap

Main Computer

Panel

Unit

Power Supply

Axis Computer

Hot Plug (option)

38. © ABB Robotic May 8, 2017

Example of Industrial Robot– IRB 6700

Large robot- 6 Axis

39. © ABB Robotic May 8, 2017

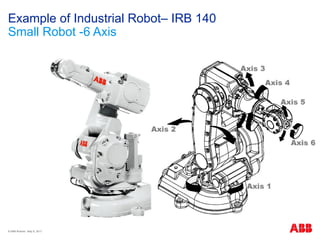

Example of Industrial Robot– IRB 140

Small Robot -6 Axis

40. © ABB Robotic May 8, 2017

Example of Industrial Robot– IRB 460

4 Axis Robot

41. © ABB Robotic May 8, 2017

Example of Industrial Robot– IRB 360

Parallel Robot- 4 Axis

42. 43. The ABB robot family

Reach up to 3.5m

Payload up to 630kg

© ABB Robotic May 8, 2017

44. Small robot family

Payload 3kg to 10kg

IRB 120 & 120T

3kg 0.58m 7kg 0.7m

IRB 1200

5kg 0.9m

IRB 1200 IRB 140 & 140T

6kg 0.81m

IRB 1600

6kg &10kg 1.2m

IRB 1600

6kg &10kg 1.45m

IRB 1600ID

4kg 1.5m

IRB 1520ID

4kg 1.5m

© ABB Robotic May 8, 2017

45. Medium robot family

Payload 8kg to 60kg

IRB 2600ID IRB 2600ID

8kg 2.0m 15kg 1.85m

IRB 2400 IRB 2600 IRB 2600

12kg 1.85m

12kg & 20kg 1.65m

12kg & 20kg 1.55m

© ABB Robotic May 8, 2017

46. Medium robot family

Payload 8kg to 60kg

IRB 4400

IRB 4600 IRB 4600

IRB 4600

20kg 2.5m

60kg 1.96m

45kg & 60kg 2.05m

40kg 2.55m

© ABB Robotic May 8, 2017

47. Large robot family

Payload 90kg to 650kg

IRB 6640

185kg 2.8m

IRB 6640

205kg 2.75m

IRB 6640

235kg 2.55m

IRB 6640

130kg 3.2m

IRB 6640ID

200kg 2.55m

180kg 2.55m

IRB 6640

IRB 6640ID

170kg 2.75m

© ABB Robotic May 8, 2017

48. Large robot family

Payload 90kg to 630kg

IRB 6660 Pre-machining

IRB 6620

IRB 6660 Press Tending

IRB 6650S

IRB 6620LX

205kg 1.9m 130kg 3.1m

150kg 2.2m 90kg & 200kg 3.0m & 3.9m

150kg 1.9m

© ABB Robotic May 8, 2017

49. The IRB 6700 Large Robot Family

IRB 6700

175kg 3.05m

300kg 2.7m

IRB 6700

240kg 3.00m

IRB 6700

IRB 6700

150kg 3.2m

IRB 6700

155kg 2.8m 200kg 2.6m

IRB 6700

IRB 6700

205kg 2.8m

IRB 6700

235kg 2.65m

© ABB Robotic May 8, 2017

50. Large robot family

Payload 90kg to 630kg

400kg 2.55m

340kg 2.8m

500kg* 2.55m

IRB 7600

325kg 3.1m

150kg 3.5m

IRB 7600

* 630kg capacity

with wrist down

IRB 7600 IRB 7600

IRB 7600

© ABB Robotic May 8, 2017

51. High speed pickers Palletizers

Top loader and packer

Dedicated 4 axis robot family

Overview - picking, packing, palletizing

Serving fully

integrated

packing lines

© ABB Robotic May 8, 2017

52. Dedicated 4 axis FlexPicker family

High speed pickers from 1kg to 8kg

Stainless steel

option

Protection to

IP55/67/IP69K

Clean Room ISO

Class 5-7

Wash Down

3kg 1,130mm

1kg 800mm 1kg 1,130mm

1kg 1,600mm 8kg 1,130mm

6kg 1,130mm

© ABB Robotic May 8, 2017

53. Dedicated 4 axis robot family

Top Loaders & Palletizers

IRB 260

IRB 660 IRB 660

IRB 460

IRB 760

+ Grippers

30kg 1.5m 110kg 2.4m

450kg 3.18m

180kg 3.15m 250kg 3.15m

© ABB Robotic May 8, 2017

54. Compact version

Panel mount version

Robot control family

Overview

Multi-robot control, up to 36 axis, with MultiMove

Programmable user interface with intuitive joystick control via

FlexPendant

World leading motion control with TrueMove and QuickMove

“Next generation safety” with SafeMove

Powerful connectivity through network interfaces

Remote Service option

Modular version

© ABB Robotic May 8, 2017

55. Paint robot family

With dedicated controller

IRB 52 IRB 580

IRB 5400 IRB 5400 with Rail IRC5P

All ABB paint

robots, paint

controllers

and paint

programming

units are

explosion

protected.

See data sheets

for more

information

IRB 5500

13kg 3.0m & 5.8m

7kg 1.22m & 1.45m 10kg 2.2m & 2.6m

25kg 3.1m Paint Controller

25kg up to 20m

© ABB Robotic May 8, 2017

56. Robot process and application equipment

Fully integrated with your robot

Dress Packs

Painting Track Motions

Process Cabinets Arc Welding Spot Welding

© ABB Robotic May 8, 2017

57. Robot process and application equipment

Fully integrated with your robot

© ABB Robotic May 8, 2017

RTT tracks for small robots.

IRBT 4004, 6004, 7004 tracks for large robots.

IRT tracks for other objects.

58. Robot process and application equipment

Fully integrated with your robot

Motors

Positioners Grippers

Press tending tools Gearboxes Additional axis

© ABB Robotic May 8, 2017

59. Robot process and application equipment

Fully integrated with your robot

L type positioner (5 sizes)

C type positioner (2 sizes)

R type positioner (3 sizes)

K type positioner (3 sizes)

A type positioner

(3 sizes)

B type positioner (3 sizes)

D type positioner

(2 sizes)

© ABB Robotic May 8, 2017

60. Robot process and application equipment

Fully integrated with your robot

FlexLifter (3 models)

FlexPLP (3 models)

© ABB Robotic May 8, 2017

61. Robot process and application equipment

Fully integrated with your robot

Force control

Vision Dispensing

Dusting Press synchronization Door openers

© ABB Robotic May 8, 2017

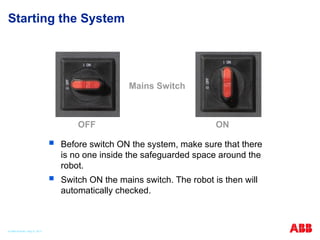

62. 63. Starting the System

Before switch ON the system, make sure that there

is no one inside the safeguarded space around the

robot.

Switch ON the mains switch. The robot is then will

automatically checked.

Mains Switch

OFF ON

© ABB Robotic May 8, 2017

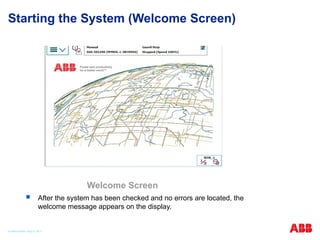

64. 65. Starting the System (Welcome Screen)

After the system has been checked and no errors are located, the

welcome message appears on the display.

Welcome Screen

© ABB Robotic May 8, 2017

66. © ABB Robotic May 8, 2017

FlexPendant Overview

Status bar

User defined keys

Windows

button

Program execution keys

E-Stop

3D

Joystick

Enabling

device

USB port

Quickset menu

Jogging

keys

67. 68. © ABB Robotic May 8, 2017

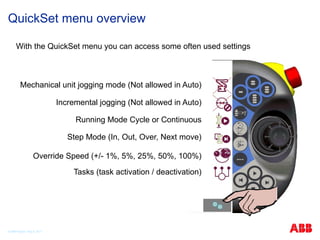

QuickSet menu overview

With the QuickSet menu you can access some often used settings

Mechanical unit jogging mode (Not allowed in Auto)

Incremental jogging (Not allowed in Auto)

Running Mode Cycle or Continuous

Step Mode (In, Out, Over, Next move)

Override Speed (+/- 1%, 5%, 25%, 50%, 100%)

Tasks (task activation / deactivation)

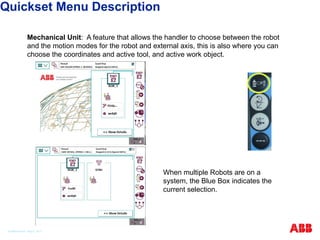

69. Mechanical Unit: A feature that allows the handler to choose between the robot

and the motion modes for the robot and external axis, this is also where you can

choose the coordinates and active tool, and active work object.

When multiple Robots are on a

system, the Blue Box indicates the

current selection.

Quickset Menu Description

© ABB Robotic May 8, 2017

70. Show/Hide Details: By Tapping on the Show Details button, your current selections

can be viewed. The button will change back to Hide Details if hit again allowing you

to minimize that screen.

The selected Coordinate system,

and Motion Mode setting is

displayed when Show Details is

pressed. Tap on one of the other

selections to change that property.

Quickset Menu Description

© ABB Robotic May 8, 2017

71. Increment: Use incremental movement to jog the robot in small steps, which

enables very precise positioning.

Each time the joystick is

deflected, the robot moves one

step(increment). If the joystick is

deflected for one or more

seconds, a sequence of steps, (at

a rate of 10 steps per second),

will be performed as long as the

joystick is deflected.

Default mode is no increment,

then the robot move continuously

when the joystick is deflected.

Quickset Menu Description

© ABB Robotic May 8, 2017

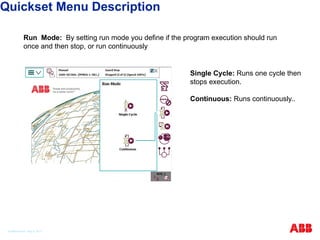

72. Run Mode: By setting run mode you define if the program execution should run

once and then stop, or run continuously

Single Cycle: Runs one cycle then

stops execution.

Continuous: Runs continuously..

Quickset Menu Description

© ABB Robotic May 8, 2017

73. Step Mode: Selecting the different Step Mode features allows you to define how the

Step-by-Step program execution will function.

Step Into: Steps into called routines

and executes them step-by-step.

Step Out: Executes the remains of

the current routine and then stops at

the next instruction in the routine

from which the current routine was

called.

Step Over: Called routines are

executed in one single step.

Next Move: Steps to the next move

instruction. Stops before and after

movement instructions, for example

to modify positions.

Quickset Menu Description

© ABB Robotic May 8, 2017

74. Speed: The Speed settings apply to the current Operating Mode. But, if you

decrease the speed in Automatic Mode, the setting also applies to Manual mode if

you change back to that mode. The current running Speed, in relation to Max, is

displayed above the buttons.

-1% & +1%: Decrease & Increase

running speed in steps of 1%.

-5% & +5%: Decrease & Increase

running speed in steps of 5%.

25%: Run at quarter speed (25%).

50%: Run at half speed (50%).

100%: Run at full speed (100%).

Quickset Menu Description

© ABB Robotic May 8, 2017

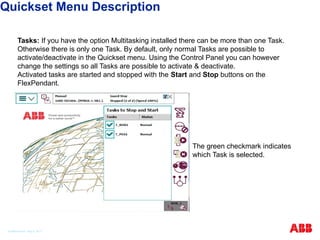

75. Tasks: If you have the option Multitasking installed there can be more than one Task.

Otherwise there is only one Task. By default, only normal Tasks are possible to

activate/deactivate in the Quickset menu. Using the Control Panel you can however

change the settings so all Tasks are possible to activate & deactivate.

Activated tasks are started and stopped with the Start and Stop buttons on the

FlexPendant.

The green checkmark indicates

which Task is selected.

Quickset Menu Description

© ABB Robotic May 8, 2017

76. 77. Exercise

1. Go to your assigned robots and practice jogging the robot

using the Quick Set button and the joystick.

2. What happens when you press the top center box on the Flex

Pendant?

3. Look at the Event Log. What was the last event that occurred?

4. Challenge: Find and Change the FlexPendant display

Brightness and contrast.

5. Challenge: Find and Change the FlexPendant for either Right

or Left handed users.

6. Practice pressing buttons on the FlexPendant. If you have any

questions ask the instructor.

© ABB Robotic May 8, 2017

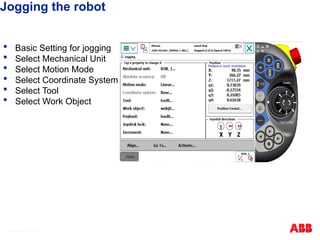

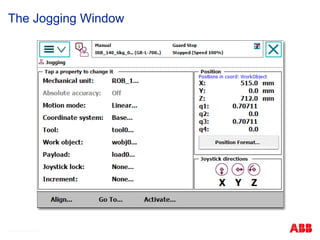

78. 79. 80. Jogging the robot

Basic Setting for jogging

Select Mechanical Unit

Select Motion Mode

Select Coordinate System

Select Tool

Select Work Object

© ABB Robotic May 8, 2017

81. © ABB Robotic May 8, 2017

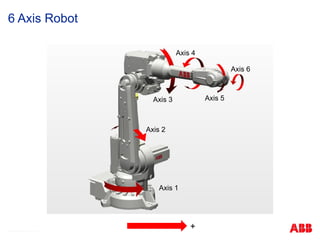

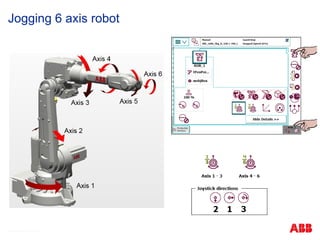

6 Axis Robot

Axis 2

Axis 3

Axis 4

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

Axis 6

+

82. © ABB Robotic May 8, 2017

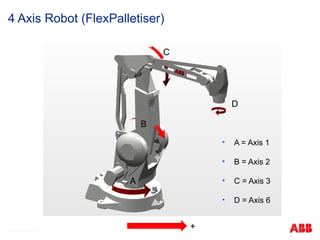

4 Axis Robot (FlexPalletiser)

• A = Axis 1

• B = Axis 2

• C = Axis 3

• D = Axis 6

A

B

C

D

+

83. © ABB Robotic May 8, 2017

3 / 4 Axis Robot (FlexPicker)

1

3

2

Y

X

4

Z Base coordinate system

84. 85. 86. © ABB Robotic May 8, 2017

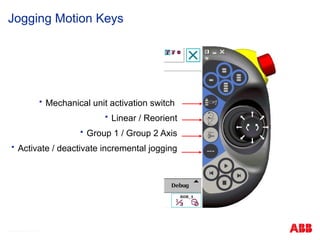

Jogging Motion Keys

Mechanical unit activation switch

Linear / Reorient

Group 1 / Group 2 Axis

Activate / deactivate incremental jogging

87. 88. 89. © ABB Robotic May 8, 2017

Incremental Jogging

Greater jogging control

Small = 0.05mm

Medium = 1mm

Large 5mm

User from 0 to 5mm

Show values to edit User

2

1

3

90. © ABB Robotic May 8, 2017

Jogging collisions

Disabling Jog supervision allows robot to be jogged after collision

‘Collision Detection’ Software option (613-1), required

Path supervision is not effected only jog supervision

Try before releasing brakes

Disabled

91. © ABB Robotic May 8, 2017

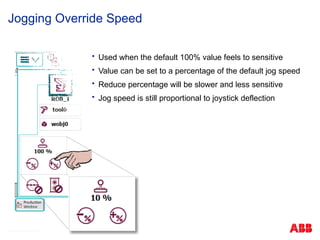

Jogging Override Speed

Used when the default 100% value feels to sensitive

Value can be set to a percentage of the default jog speed

Reduce percentage will be slower and less sensitive

Jog speed is still proportional to joystick deflection

92. 93. © ABB Robotic May 8, 2017

Jogging the Robot

-Y +Y

-X

-Z

+Z

+X

+X

+Y

+Z

-Y +Y

-X

-Z

+Z

+X

X

Z

Y

-2

-1 +1

+2

-3

+3

+1

-1

+2

-2

+3

-3

-4 +4

-5

+5

-6

+6

-4

+4

+5

-5 +6

-6

94. © ABB Robotic May 8, 2017

Z

X

Y

WorkObject

Coordinate

Coordinate System

Base

Coordinate

Z

Y

X

Tool

Coordinate

World)

Z

Y

X

Z

Y

X

95. © ABB Robotic May 8, 2017

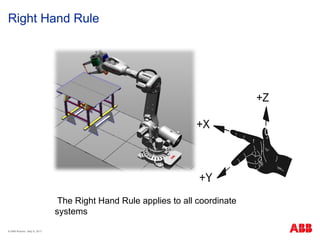

Right Hand Rule

The Right Hand Rule applies to all coordinate

systems

96. 97. © ABB Robotic May 8, 2017

Position the robot joints

Major Axis

Minor Axis

Increments where required

Position the tool using Linear relative to:

World / Base coordinates

Tool coordinates

Work object coordinates

Increments where required

Position the tool using Orientation relative to:

Tool / Base and Work object coordinates

Practice Tool Alignment

Jogging demonstration

98. 99. © ABB Robotic May 8, 2017

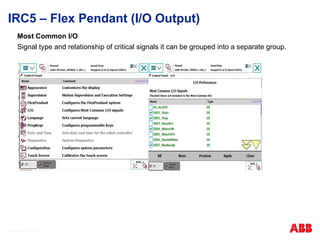

IRC5 – Flex Pendant (I/O Output)

Inputs and Outputs Window

I/O signal properties is used to view the input and output signals and their

names, values and type

Signals are configured with system parameters

100. © ABB Robotic May 8, 2017

IRC5 – Flex Pendant (I/O Output)

I/O Unit status is recognized by the system ( Board )

Individual input/output signal characteristics can retrieval and manipulate.

Manual operation is only allowable force for the individual signals.

The output signal operation Off (value 0) and On (value 1)

Input Signal Operation: First, press simulation, it can be operated via the same method.

101. © ABB Robotic May 8, 2017

IRC5 – Flex Pendant (I/O Output)

Most Common I/O

Signal type and relationship of critical signals it can be grouped into a separate group.

102. IRC5 – Flex Pendant (I/O Output)

© ABB Robotic May 8, 2017

Viewing signal

Tap Menu

Tap Inputs and Outputs

Tap View.

Select signal type

103. 104. © ABB Robotic May 8, 2017

Tool Centre Points (TCP)

+X

+Y

+Z

Wrist Coordinate system

Tool Coordinate system

105. © ABB Robotic May 8, 2017

Tool Centre Point theory

The position & movement of the robot is always relative to the active TCP.

TCP’s are defined as being somewhere at the end of the tool.

Many TCP’s may be defined, but only one active at any one time.

Can be programmed manually but only if accurate TCP values are known.

Normally the robot is used to define its TCP.

If tool is damaged or replaced, don’t modify program positions, just redefine

the tool.

106. © ABB Robotic May 8, 2017

Default Orientation (same direction as Wrist coordinate system)

TCP & Z Just Z direction defined (X stays in same plane as wrist)

TCP & Z, X both Z and X defined

From 3 to 9 approach points

Tool Centre Point Definition Methods

107. © ABB Robotic May 8, 2017

Example of TCP with default orient

No rotational difference from the wrist coordinate system

108. © ABB Robotic May 8, 2017

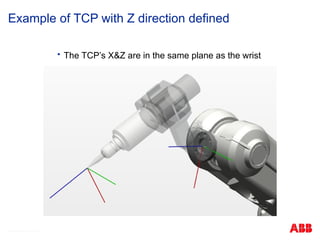

Example of TCP with Z direction defined

The TCP’s X&Z are in the same plane as the wrist

109. © ABB Robotic May 8, 2017

Example of TCP with Z&X directions defined

The TCP’s X&Z directions are rotated differently to the wrist

110. © ABB Robotic May 8, 2017

1

2

3

4

1

2

3

Plan view

4

TCP Definition – Default Orient

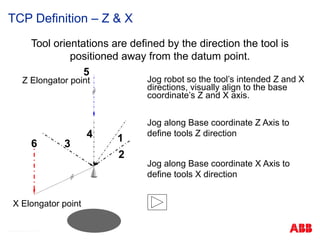

111. © ABB Robotic May 8, 2017

1

3

6

5

4

Jog robot so the tool’s intended Z and X

directions, visually align to the base

coordinate’s Z and X axis.

Jog along Base coordinate Z Axis to

define tools Z direction

Jog along Base coordinate X Axis to

define tools X direction

Z Elongator point

2

Tool orientations are defined by the direction the tool is

positioned away from the datum point.

X Elongator point

TCP Definition – Z & X

112. © ABB Robotic May 8, 2017

Tool Centre Point Definition Method

Menu

Program data

Select tooldata

Show data

New…

Name tool

Initial value or OK and then select tool in list and Edit Value

Mass:= type in kg and Centre of Gravity

Press OK

Press Edit

Select Define

Select Method and number of Points

Select Point 1, jog robot to calibration position and press Modify Position

Repeat for remaining points

Press OK

You will need to activate your TCP in the jog window

113. © ABB Robotic May 8, 2017

Exercise

Create a Tool Centre Point

Exercise 2

114. 115. © ABB Robotic May 8, 2017

Programming Introduction

Load an existing program

Introduction to basic move instructions and data

Programming move instructions

Modifying Instructions and data

Save a program

Rename a program

Delete a program

116. © ABB Robotic May 8, 2017

Program Modules.mod

Program Data

Main

Routine

Routines

<?xml version="1.0" encoding="ISO-8859-1" ?>

<Program>

<Module>MainModule.mod</Module>

<Module>ModuleA.mod</Module>

<Module>ModuleB.mod</Module>

</Program>

Program Data

Routines

Program Data

Routines

System Modules.sys

Program Task Structure

117. Rapid Program

© ABB Robotic May 8, 2017

A program is the list of command that tells robot what to do

Programming language: RAPID (Robotics Application Programming Interactive Dialogue)

- 4th generation language. RobotWare is written in C language, 3rd generation language.

Program = data + Instruction/commands (Instruction/commands are handled in units of

routines)

A program operates in conjunction with a program module and a system module, and

there is only one program in the program memory. (Extension: *. pgf)

118. 119. © ABB Robotic May 8, 2017

Modules

A module contains routines and data’s.

The module that contains the main routine is the MainModule

System modules are always present in memory and can be used to save your

default data

Filename extensions are

XXXXX.mod Program Module

XXXXX.sys System Module

XXXXX.pgf Program File

120. © ABB Robotic May 8, 2017

Routines

Repetitive instruction sequences, that occur frequently in the program, should

form their own routines.

Routines separate the program into smaller more easily understood parts,

these can then be called anywhere in the program using the ProcCall

instruction.

A Max of 16 characters are allowed for naming routines, meaningful names

will make the program easier to follow and operate.

Routines can be tested by moving the Program Pointer to a routine. (Debug)

Routines are called within the program using the instruction ‘Procall’

121. © ABB Robotic May 8, 2017

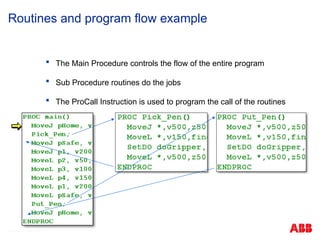

Routines and program flow example

The Main Procedure controls the flow of the entire program

Sub Procedure routines do the jobs

The ProCall Instruction is used to program the call of the routines

122. © ABB Robotic May 8, 2017

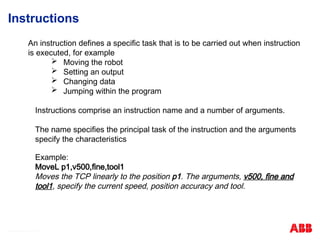

Instructions

An instruction defines a specific task that is to be carried out when instruction

is executed, for example

Moving the robot

Setting an output

Changing data

Jumping within the program

Instructions comprise an instruction name and a number of arguments.

The name specifies the principal task of the instruction and the arguments

specify the characteristics

Example:

MoveL p1,v500,fine,tool1

Moves the TCP linearly to the position p1. The arguments, v500, fine and

tool1, specify the current speed, position accuracy and tool.

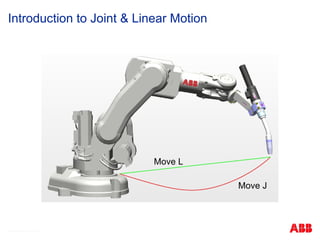

123. © ABB Robotic May 8, 2017

Introduction to Joint & Linear Motion

Move L

Move J

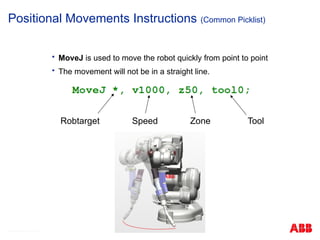

124. MoveJ is used to move the robot quickly from point to point

The movement will not be in a straight line.

© ABB Robotic May 8, 2017

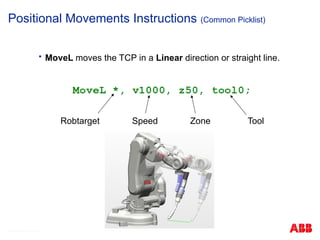

Positional Movements Instructions (Common Picklist)

Robtarget Speed Zone Tool

125. © ABB Robotic May 8, 2017

Positional Movements Instructions (Common Picklist)

MoveL moves the TCP in a Linear direction or straight line.

Robtarget Speed Zone Tool

126. Zones

© ABB Robotic May 8, 2017

z

MoveL p40, v1000, z50, tool0;

MoveL p30, v400, z20, tool0;

Zone data describes how close to the destination position

the axes must be before the next instruction can be executed

Zone size

127. © ABB Robotic May 8, 2017

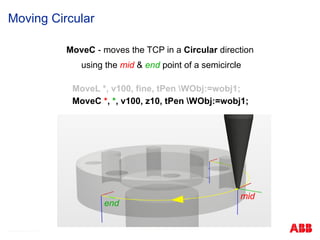

Moving Circular

MoveC - moves the TCP in a Circular direction

using the mid & end point of a semicircle

MoveL *, v100, fine, tPen WObj:=wobj1;

MoveC *, *, v100, z10, tPen WObj:=wobj1;

mid

end

128. © ABB Robotic May 8, 2017

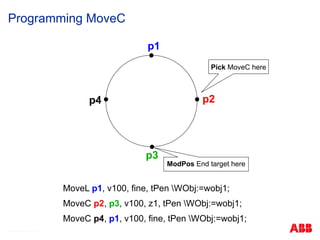

Programming MoveC

p1

p2

p3

p4

ModPos End target here

Pick MoveC here

MoveL p1, v100, fine, tPen WObj:=wobj1;

MoveC p2, p3, v100, z1, tPen WObj:=wobj1;

MoveC p4, p1, v100, fine, tPen WObj:=wobj1;

129. Input Instruction

© ABB Robotic May 8, 2017

Input processing instructions are to wait until you are satisfied the specified conditions.

Conditions can be such signal conditions, the time, the logical operation.

WaitDI di05_AutoReady, 1;

WaitTime 0.5;

WaitUntil di06_Ready = 1;

WaitUntil di05=1 AND di07=0;

WaitUntil di02=1 OR di03=1...;

Signal state

Signal Name

130. 131. 132. 133. © ABB Robotic May 8, 2017

Creating New programs

New Programs can be created in the Program Editor

Program names can not start with a number

If a program allready exists, it will be overwritten

New programs are temporaraly called ’NewProgramName’

A ‘main’ routine is created within a ‘MainModule’

134. Loading Programs

Loading whole programs will overwrite existing

programs

Each task will have its own program

© ABB Robotic May 8, 2017

135. 136. Creating a new Module

ABB menu

Tap Program Editor.

Tap Modules.

Tap File, then tap New Module.

Tap ABC... and use the soft keyboard to enter the new module's name.

Then tap OK

Select which type of module to be created:

• Program

• System

Then tap OK.

© ABB Robotic May 8, 2017

137. 138. How to create and program routines.

Must be in the Program Editor.

Tap Routines : File

New Routine : Tap “ABC…”

to change the name.

Tap OK.

Select the routine.

Tap Show routine.

Creating Routines

© ABB Robotic May 8, 2017

139. To add instructions to your program:

Tap Add Instruction

Jog robot into position

Tap MoveJ or MoveL

Jog robot to next position

Repeat

Inserting Move Instructions

© ABB Robotic May 8, 2017

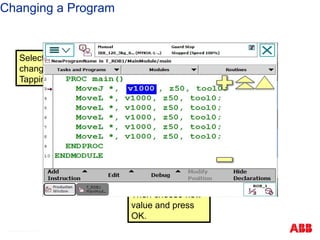

140. 141. Select the instruction or target to be changed (Step is recommended)

Jog robot to the desired position

Press Modify Position

Modify Position

© ABB Robotic May 8, 2017

142. 143. 144. 145. 146. Create a new routine called PickPen

Activate your TCP

Program the robot to pick up the pen

Test this routine (debug ‘PP to routine’)

Copy this routine and edit the output instruction to put the pen down

Test the duplicated routine (debug ‘PP to routine’)

Call these routines within your main routine (ProCall instruction)

Test your Main Routine (debug ‘PP to main’)

Save your program as ‘Exercise_3’

Routines Exercise

© ABB Robotic May 8, 2017

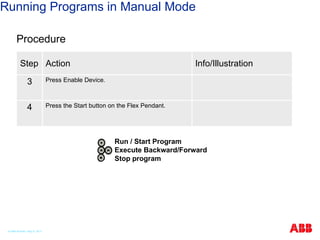

147. 148. 149. Running Programs in Manual Mode

Procedure

Step Action Info/Illustration

1 Switch the robot to Manual Mode.

2

DANGER!

Before running the robot, please observe the safety

information in section DANGER – moving

manipulators are potentially lethal!

© ABB Robotic May 8, 2017

150. Running Programs in Manual Mode

Procedure

Step Action Info/Illustration

3 Press Enable Device.

4 Press the Start button on the Flex Pendant.

Run / Start Program

Execute Backward/Forward

Stop program

© ABB Robotic May 8, 2017

151. Starting Execution

Procedure

Step Action Info/Illustration

1 To run a selected execution use the “Run" button

on the Flex Pendant's hardware button key set.

Run / Start Program

Execute Backward/Forward

Stop program

© ABB Robotic May 8, 2017

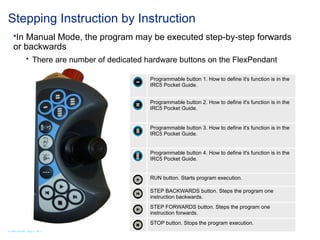

152. Stepping Instruction by Instruction

In Manual Mode, the program may be executed step-by-step forwards

or backwards

There are number of dedicated hardware buttons on the FlexPendant

Programmable button 1. How to define it's function is in the

IRC5 Pocket Guide.

Programmable button 2. How to define it's function is in the

IRC5 Pocket Guide.

Programmable button 3. How to define it's function is in the

IRC5 Pocket Guide.

Programmable button 4. How to define it's function is in the

IRC5 Pocket Guide.

RUN button. Starts program execution.

STEP BACKWARDS button. Steps the program one

instruction backwards.

STEP FORWARDS button. Steps the program one

instruction forwards.

STOP button. Stops the program execution.

© ABB Robotic May 8, 2017

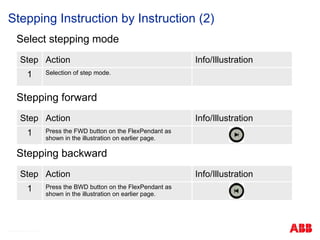

153. Stepping Instruction by Instruction (2)

Select stepping mode

Step Action Info/Illustration

1 Selection of step mode.

Stepping forward

Step Action Info/Illustration

1 Press the FWD button on the FlexPendant as

shown in the illustration on earlier page.

Stepping backward

Step Action Info/Illustration

1 Press the BWD button on the FlexPendant as

shown in the illustration on earlier page.

© ABB Robotic May 8, 2017

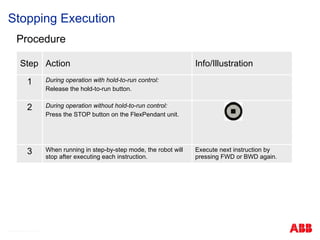

154. Stopping Execution

Procedure

Step Action Info/Illustration

1 During operation with hold-to-run control:

Release the hold-to-run button.

2 During operation without hold-to-run control:

Press the STOP button on the FlexPendant unit.

3 When running in step-by-step mode, the robot will

stop after executing each instruction.

Execute next instruction by

pressing FWD or BWD again.

© ABB Robotic May 8, 2017

155. 156. Saving program in IRC5

A folder with the same name as the program is created

This folder contains the MainModule, Sub modules and the program file

The program file (.pgf),is an extensible mark-up language, ‘XML’, file that lists all

program modules in the task

System Modules are NOT saved

© ABB Robotic May 8, 2017

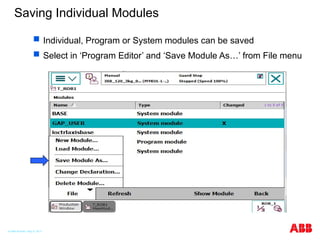

157. 158. Saving Individual Modules

Individual, Program or System modules can be saved

Select in ‘Program Editor’ and ‘Save Module As…’ from File menu

© ABB Robotic May 8, 2017

159. 160. Exercise

1. Go to your assigned robots and create a simple program as described in

this section. Then test your program. Each student should make their own

program. (Do not use I/O until all participants have created and tested their

programs.)

2. What happens when you press the E-Stop button while the robot is

running? Can you restart the robot from where it stopped?

3. Save the program to the Flash Drive.

4. Practice pressing buttons on the FlexPendant. If you have any questions

ask the instructor.

© ABB Robotic May 8, 2017

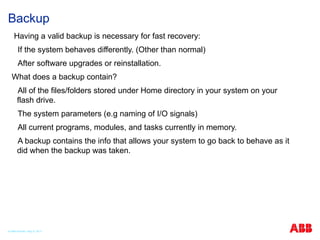

161. 162. Backup

Having a valid backup is necessary for fast recovery:

If the system behaves differently. (Other than normal)

After software upgrades or reinstallation.

What does a backup contain?

All of the files/folders stored under Home directory in your system on your

flash drive.

The system parameters (e.g naming of I/O signals)

All current programs, modules, and tasks currently in memory.

A backup contains the info that allows your system to go back to behave as it

did when the backup was taken.

© ABB Robotic May 8, 2017

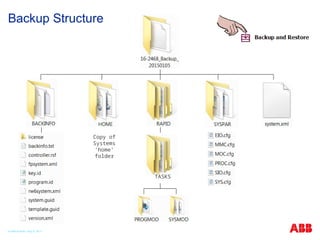

163. 164. Backup and Restore – Backup the System

ABB recommends performing a backup:

Before installing new Robot Ware

Before making any major changes to instructions and/or parameters

to facilitate the previous setting

After making any changes to instructions and/or parameters and

testing the new settings to retain the new settings

Remarks:

Always

Give your backup a good name. Push to go to the key board to

type the name of the backup.

Pay attention to the Backup Path, this is the location where the

backup will be stored. Push the … to change the location.

You should create a Backup folder to store the file in.

© ABB Robotic May 8, 2017

165. 166. 167. 168. Event Messages are divided into.

Information

Example: Hold to run must be pressed.

Information is stored in the log.

Warning

Example : Manual movement full speed is selected.

The operator is informed about a potential risk.

Error

Example : Motor On when Emergency Stop is active.

The system cannot operate before a measure is carried

out.

Introduction

© ABB Robotic May 8, 2017

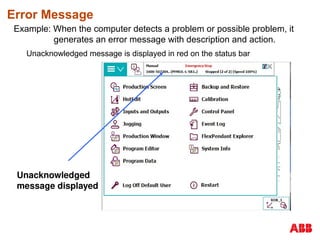

169. 170. 171. Error Message

Example: When the computer detects a problem or possible problem, it

generates an error message with description and action.

Unacknowledged message is displayed in red on the status bar

Unacknowledged

message displayed

172. Event Message Content

An Event Message consists of

Description

Consequences (optional)

Probable causes (optional)

Action (optional)

Tap arrow to scroll down

in message!

© ABB Robotic May 8, 2017

173. Reading Event Logs on the FlexPendant

Via ABB - Main menu

Tap status bar – Short cut

Tap on Status Bar to see

Event log.

Or Tap ABB then Event

Log to see Event log.

174. 175. Scroll the list with the yellow arrows

Tap on a specific message to get more information

Event Log

© ABB Robotic May 8, 2017

176. Event Log

Logs are stored under different topics

Tap view and select the topic of interest

Topic common consist of a mixture of the last created logs

Log Messages

Common 150

All others 20

177. Event Categories

Category Error number Area__________________

Operational 10xxx Operational Status

System 20xxx Panel unit

Hardware 30xxx Board Failure

Program 40xxx Programming

Motion 50xxx Movement problem

Operation 60xxx Flex Pendant Handling

I/O communication 70xxx I/O board communication errors

ArcWeld 11xxxx Process

SpotWeld 12xxxx Process

Paint 13xxxx Process

Refer to the error number when support is

needed!

© ABB Robotic May 8, 2017

178. 179. 180. 181. Restart (Warm Start)

When: New hardware, SYSFAIL or change in configuration

Result: Current system is restarted. Program pointer are restored

Reset System (I- start)

When: Add RobWare for a new process

All saved, Restart with default parameters.

Modules & program not loaded

Reset Rapid (P-Start)

When: E.g. Changing data in parallel tasks

All data saved on image file for loading purpose

RAPID programs not reloaded

Summary of Restart Alternatives

© ABB Robotic May 8, 2017

182. Summary of Restart Alternatives

Start Boot Application (E-start)

When: Change to an existing system: E.g: Glue to Arcweld

All data are saved on an image file, for loading purpose only

C-Start (Cold start) Removes all user inputs and the robot software

When: E.g: A new BaseWare for a system shall be loaded

All data is erased. A boot is necessary if no other system exists in the controller

© ABB Robotic May 8, 2017

183. Special Restart Alternatives

Shutdown

When: The UPS system is not working

An image file is carried out as a normal Power Off

To start: Turn Power Off & On to restart the system

Revert to last Auto Saved (B-Start)

When: E.g. Recommend action from an error message

Returns the system to the state after the most recent shutdown by either Power

Off or Shutdown

In this case no saving is carried out as for Warm Start

Note! These alternatives are intended for special use only!

© ABB Robotic May 8, 2017

184. 185. Fine Calibrate or Rev.Count update?

Rev.Count update can easily be made with no special

tools.

Fine calibration needs special tools.

Calibration – IRC5

© ABB Robotic May 8, 2017

186. Rev.Counter

Tells how many turns the motor has rotated in the

gearbox.

If value is lost the robot cannot run any programs.

A message notifies that the Rev.Counters need to be

updated.

(e.g. If battery in SMB is drained)

Rev. Counters

If Event message The

system informs about

difference:

Update so that the robot

and the controller have

the same calibration

values

©

ABB

Inc.-184

© ABB Robotic May 8, 2017

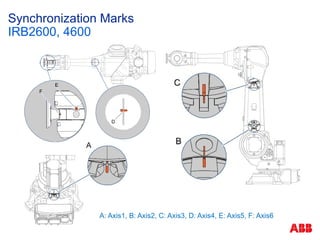

187. Updating Rev. Counters

1. Use the Joy stick and

Move the Robot to

the Calibration

Position and align

the witness marks.

© ABB Robotic May 8, 2017

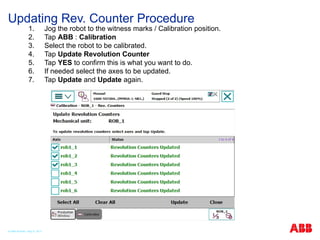

188. 189. 190. 191. 192. 193. 194. 195. 196. Updating Rev. Counter Procedure

1. Jog the robot to the witness marks / Calibration position.

2. Tap ABB : Calibration

3. Select the robot to be calibrated.

4. Tap Update Revolution Counter

5. Tap YES to confirm this is what you want to do.

6. If needed select the axes to be updated.

7. Tap Update and Update again.

© ABB Robotic May 8, 2017

197. MoveAbsJ

Create a new routine (GotoCalib)

Insert MoveAbsJ instruction

Choose star position, Debug / View Value, put all 6 axis

to zero

Checking Robot Calibration

© ABB Robotic May 8, 2017

198. Fine Calibration

Tells the current angle of motor shaft when robot is in

sync position

Is tuned in by ABB or on site with special equipment

Only needs to be retuned if a motor / gearbox is

replaced

Fine Calibration

Requires special tools!

Cannot be made correctly

by eye Measurement.

© ABB Robotic May 8, 2017

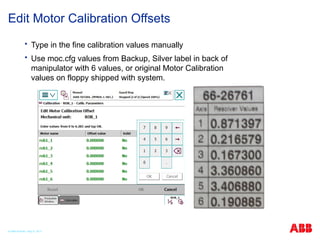

199. Type in the fine calibration values manually

Use moc.cfg values from Backup, Silver label in back of

manipulator with 6 values, or original Motor Calibration

values on floppy shipped with system.

Edit Motor Calibration Offsets

© ABB Robotic May 8, 2017

200. 201. For Emergency Service, Spare Parts, Tech

Support, Questions, Comments, Complaints….

+603 5628 4888

© ABB Robotic May 8, 2017

202. Editor's Notes #15 Most industry personnel have had Lock Out Tag Out training. We want to emphasize this training and the proper procedures on the ABB robot. #33 Explicar sobre controladores, unidade de programação e manipuladores. #34 Mostrar principais componentes do painel. #35 Mostrar painel compacto. #38 Exemplo de robô industrial.

IRB6640

Robô de grande porte com capacidade de carga indo de 130Kg à 235Kg dependendo da versão.

Robô de 6 eixos, ou seja, 6 graus de liberdade como a maioria dos robôs industriais. A ABB possui alguns robôs de 4 eixos, geralmente utilizados para aplicações de paletização onde não existe a necessidade de inclinar o produto.

Robô com alcaide de 2.55m até 3.2m dependendo da versão.

Ilustração dos eixos do robô IRB6640.

Mostrar os movimentos de cada eixo.

Eixos 1, 2 e 3 são os eixos principais do robô e são usados para movimentar o robô no espaço.

Eixos 4, 5 e 6 são o punho do robô e são usados para orientar a ferramenta do robô, ou seja, mudar o angulo de trabalho.

#39 Exemplo de robô industrial.

IRB140 robô de pequeno porte com capacidade de carga de 5Kg.

Robô de 6 eixos, ou seja, 6 graus de liberdade.

Alcance de 0.81 metros.

Ilustração dos eixos do robô IRB140.

Mostrar os movimentos de cada eixo.

Eixos 1, 2 e 3 são os eixos principais do robô e são usados para movimentar o robô no espaço.

Eixos 4, 5 e 6 são o punho do robô e são usados para orientar a ferramenta do robô, ou seja, mudar o angulo de trabalho.

#40 Exemplo de robô industrial.

IRB460 robô de médio porte com capacidade de carga de 110Kg.

Robô de 4 eixos, ou seja, 4 graus de liberdade. Geralmente usado em paletização

Alcance de 2.4 metros.

Ilustração dos eixos do robô IRB460.

Mostrar os movimentos de cada eixo.

Eixos 1, 2 e 3 são os eixos principais do robô e são usados para movimentar o robô no espaço.

Eixo 6 é usado para girar o produto.

#41 Exemplo de robô industrial.

IRB360 robô de pequeno porte com capacidade de carga de até 3Kg.

Robô de 4 eixos, ou seja, 4 graus de liberdade. Geralmente usado em aplicações de Pick’n’Place

Alcance de 1.13 metros.

Ilustração dos eixos do robô IRB360.

Mostrar os movimentos de cada eixo.

Eixos 1, 2 e 3 são os eixos principais do robô e são usados para movimentar o robô no espaço.

Eixo 4 é usado para girar o produto.

#43 From 1kg to 630kg.

From .81m to 3.5m reach.

#46 IRB 4400 is an old robot design but it is retained in the range for high demand rigidity applications like heavy materials removal applications, such as, Machining . #49 The new work horse of the Large Robot Family. The IRB 6700 is the seventh generation of ABB large robots.

. #57 ABB provides track type positioners for all types of uses. #59 ABB has a full range of positioners for moving parts in and out of a cell or for moving parts to different positions. These are used most for Arc welding. #60 These are newer product lines for leaner manufacturing. #61 Day one. 11:00 AM

This is a good time to take a lab tour to actually see some of the products desribed.

Day one. 11:30 AM Lunch #67 - HotEdit is used to tune programmed positions. This can be done in all operating

modes and even while the program is running. Both coordinates and orientation

can be tuned. HotEdit can only be used for named positions of the type robtarget.

-Inputs and outputs, I/O, are signals used in the robot system.

-The Jogging functions are found in the Jogging window. The most commonly used

are also available under the Quickset menu.

-The Program Editor is where you create or modify programs. You can open more

than one window of the Program Editor

-The Program Data view contains functions for viewing and working with data types

and instances. You can open more than one window of the Program Data, which

can be useful when working with many instances or data types.

-The Production Window is used to view the program code while the program is running.

-The Backup and Restore menu is used for performing backups and restoring the system.

-The Calibration menu is used to calibrate mechanical units in the robot system.

-The Control Panel contains functions for customizing the robot system and the FlexPendant.

-The FlexPendant Explorer is a file manager, similar to Windows Explorer, with

which you can view the file system on the controller. You can also rename, delete,

or move files or folders.

-System Info displays information about the controller and the loaded system. Here

you can find the RobotWare version and options currently in use, current keys for

control and drive modules, network connections and so on.

-Robot systems are often operated without any personnel present. The logging

function is a way to store information about past events for future reference in

order to facilitate trouble shooting.

#80 What is jogging?

To jog is to manually position or move robots or external axes using the FlexPendant

joystick #93 Mostrar tipos de movimento #94 Falar sobre os sistemas de coordenada, qual a diferença entre eles e como seleciona-los #95 Falar sobre a regra da mão direita #126 Mostrar o funcionamento da zona e da velocidade