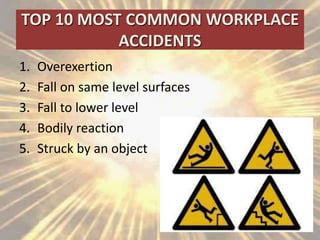

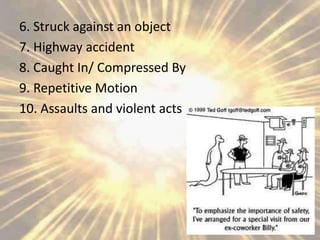

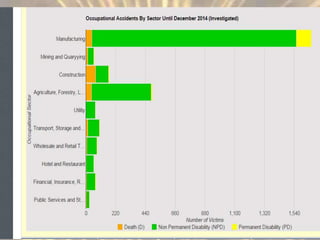

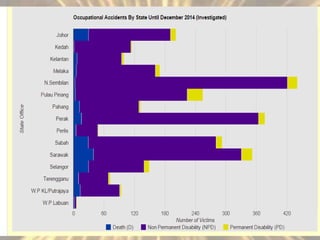

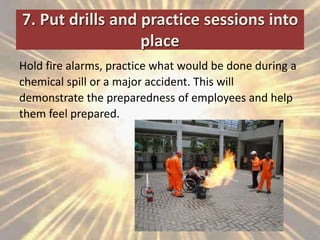

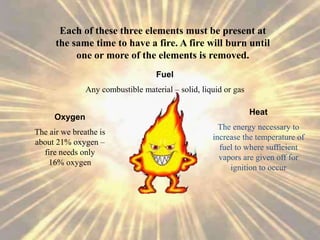

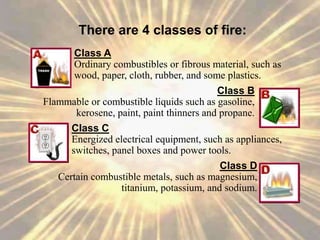

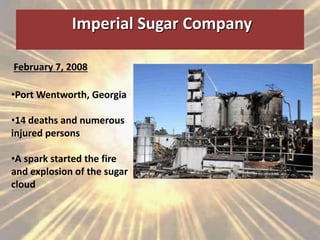

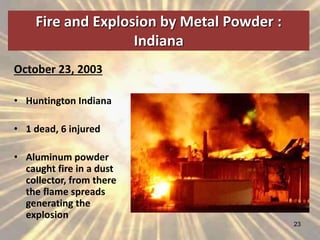

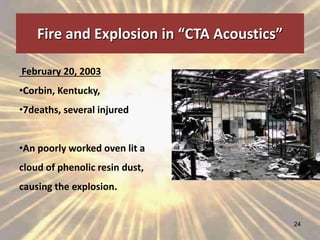

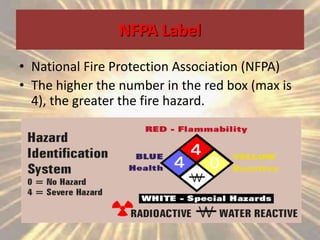

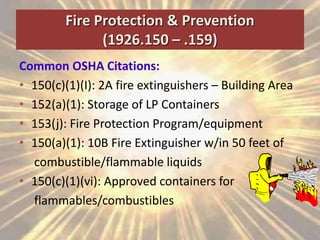

This document discusses safety indexes and fire indexes. It defines workplace safety and lists the top 10 most common workplace accidents. It then describes how to measure work safety through assessing risk exposure, evaluating safety programs, reviewing organizational culture, identifying safety leaders, and conducting inspections. The document also defines the fire triangle of fuel, oxygen, and ignition sources. It discusses historical industrial explosions and how to prevent fires at workplaces such as controlling ignition sources and limiting fuel. Safety data sheets and fire protection regulations are also summarized.