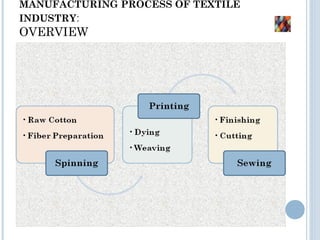

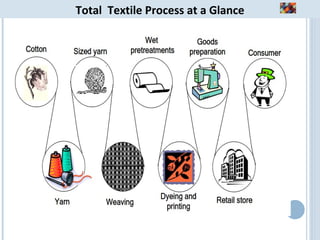

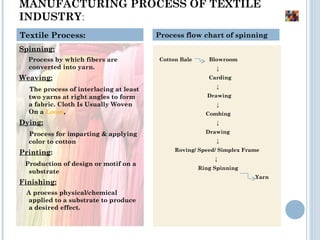

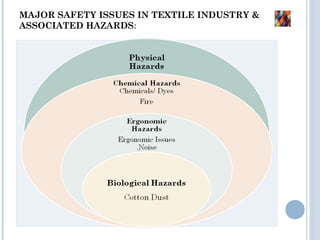

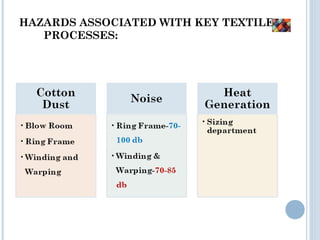

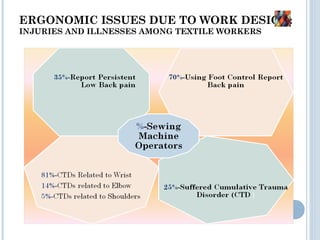

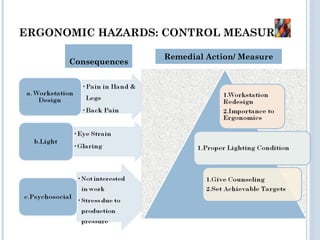

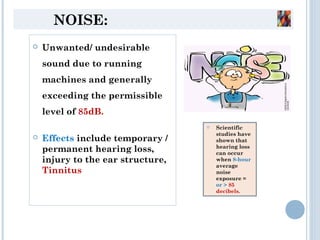

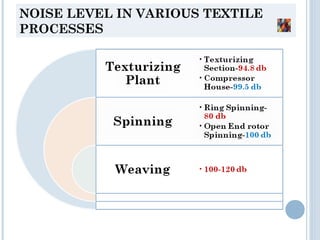

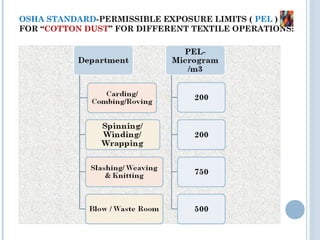

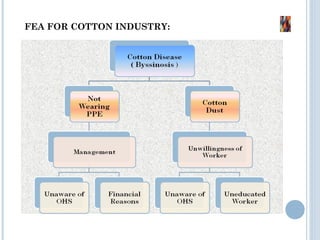

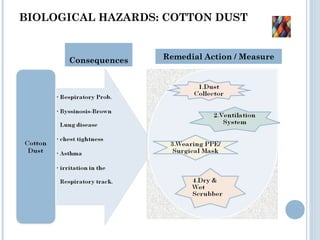

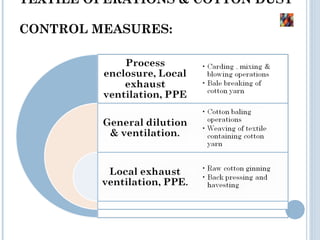

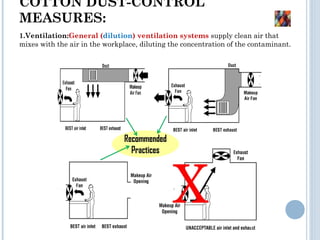

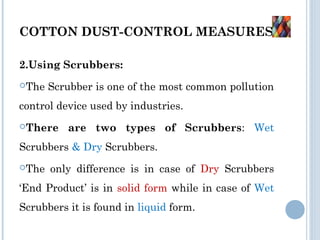

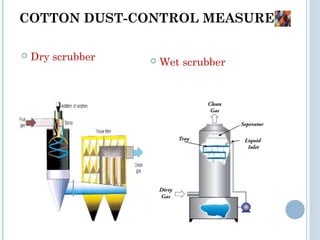

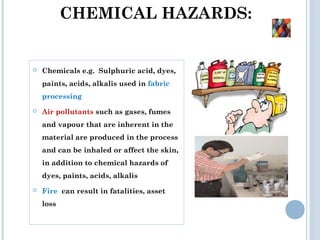

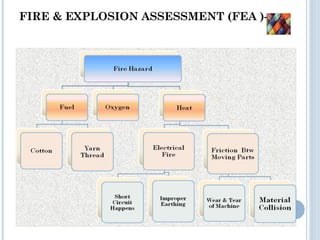

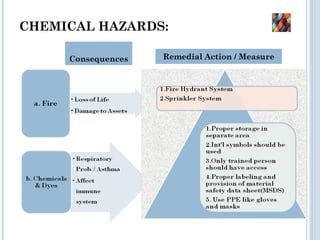

The document discusses safety in the textile sector. It provides an overview of the textile manufacturing process and the associated hazards at each stage. Workers are exposed to chemical, physical, ergonomic, and biological hazards. Chemical hazards include dyes, acids, and alkalis. Physical hazards stem from machinery. Ergonomic hazards include repetitive strain. Biological hazards notably include cotton dust, which can cause byssinosis. The document outlines control measures that can be implemented to improve safety.