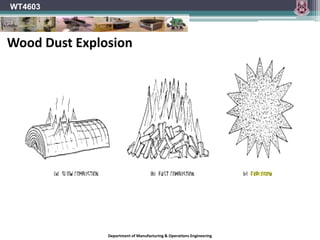

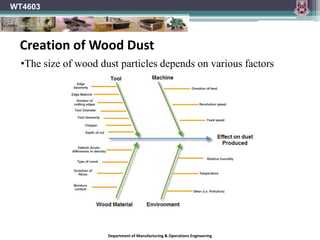

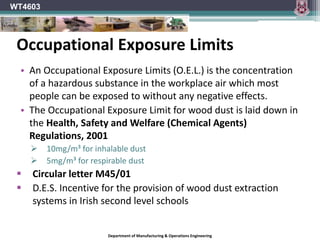

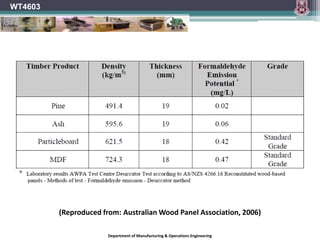

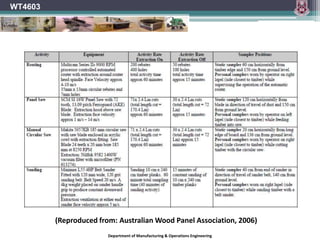

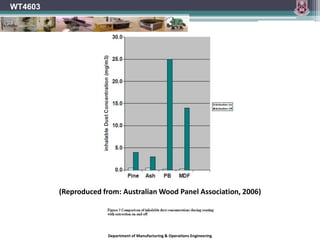

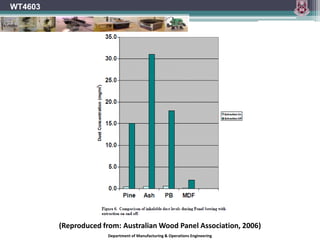

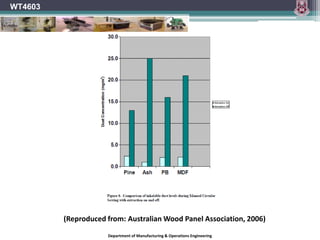

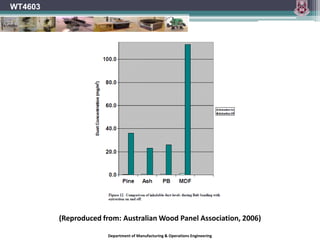

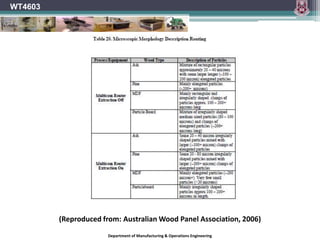

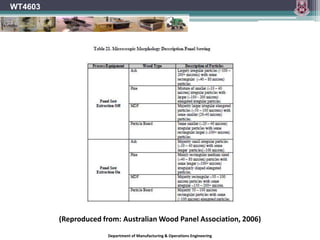

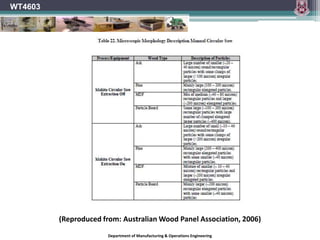

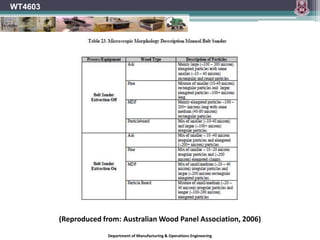

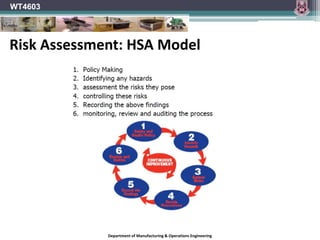

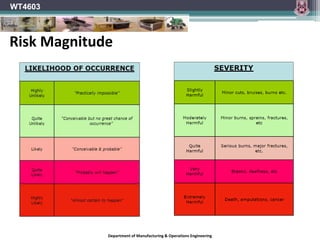

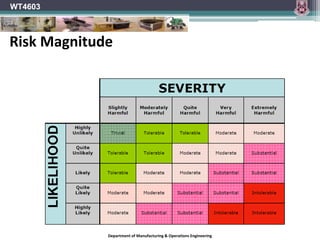

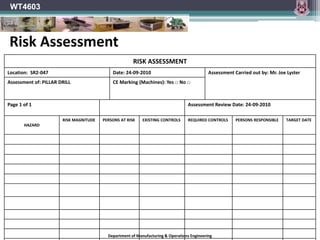

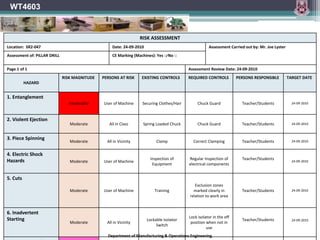

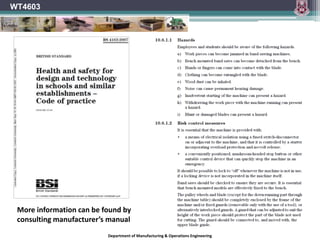

This document provides an overview of a wood processing safety and practice lecture. It discusses various hazards associated with wood dust including cancer risks from hardwood and MDF dust. It also covers occupational asthma risks from wood dust, formaldehyde risks from manufactured boards, and isocyanate risks. Additional topics include wood dust explosions, local exhaust ventilation systems for dust extraction, and occupational exposure limits. The document concludes with examples of risk assessment templates for evaluating machinery hazards and control measures.