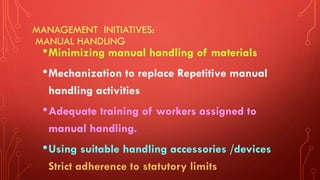

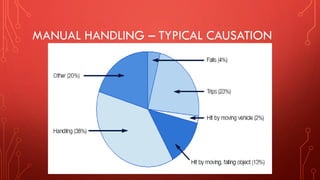

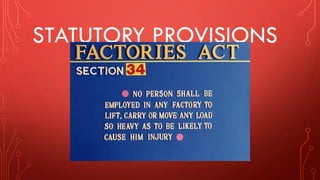

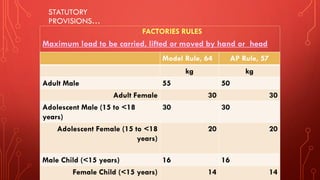

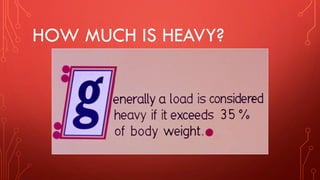

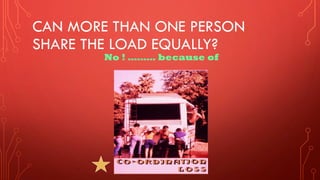

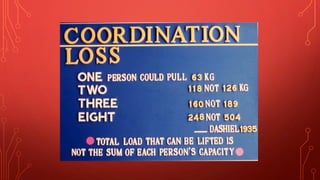

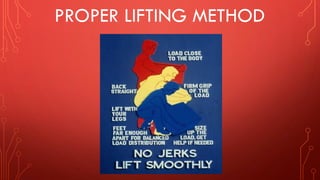

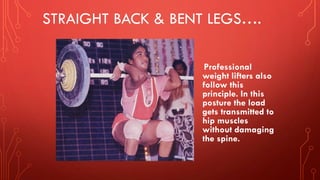

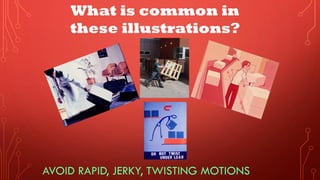

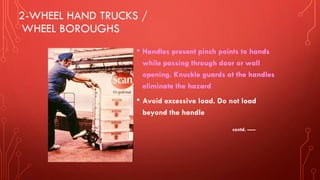

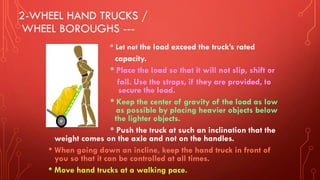

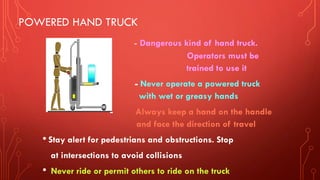

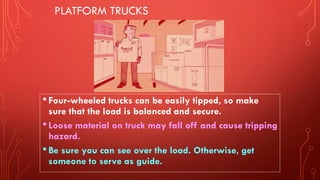

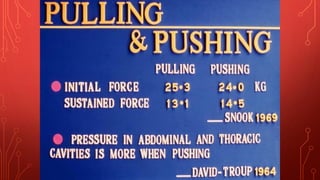

This document discusses manual handling of materials and safety considerations. It begins by defining various manual handling activities like lifting, carrying, pushing, pulling etc. It then discusses typical causes of injuries like lifting excessive weights, improper posture, jerky movements etc. The document provides statutory provisions on maximum weights that can be lifted by adults and children. It emphasizes the importance of proper lifting technique including keeping the back straight, bending knees, keeping loads close to the body and using a firm grip. Accessories for manual handling like hand trucks, wheelbarrows, platform trucks and loaders are described. The role of good housekeeping, training and use of protective equipment are also highlighted.

![LOAD ON ONE HAND CAUSES STRAIN

• Lifting & carrying a heavy

load by one hand [even if

this is within statutory limit

referred earlier] may result

in undue strain

• Distributing the load

wherever possible to two

hands is safer [eg., two

bags of 15 kg instead of

one of 30 kg]](https://image.slidesharecdn.com/3-230814122957-9eda1015/85/3-1_Manual-Material-Handling-pdf-9-320.jpg)

![LOW PALLET TRUCK

Safety Features

•Three point finger

[raise, neutral and

lower] control

•Safety loop handle

•Leak proof

hydraulic pump](https://image.slidesharecdn.com/3-230814122957-9eda1015/85/3-1_Manual-Material-Handling-pdf-47-320.jpg)

![LOADER

Can be positioned at proper height to avoid bending, stretching and

strain for shifting the load to the floor [as in the inset]](https://image.slidesharecdn.com/3-230814122957-9eda1015/85/3-1_Manual-Material-Handling-pdf-59-320.jpg)

![MOBILE SCISSOR-LIFT

[FOOT OPERATED HYDRAULIC JACK]

•Suitable for

lifting,

transporting

and loading](https://image.slidesharecdn.com/3-230814122957-9eda1015/85/3-1_Manual-Material-Handling-pdf-61-320.jpg)

![POWER-OPERATED SCISSOR-LIFT

[STATIONARY OR MOBILE]](https://image.slidesharecdn.com/3-230814122957-9eda1015/85/3-1_Manual-Material-Handling-pdf-62-320.jpg)

![COMMON PPE FOR MANUAL HANDLING

Safety Shoe [seen under

Impact Test]

Chrome leather gloves

Cotton & Canvas Gloves](https://image.slidesharecdn.com/3-230814122957-9eda1015/85/3-1_Manual-Material-Handling-pdf-66-320.jpg)