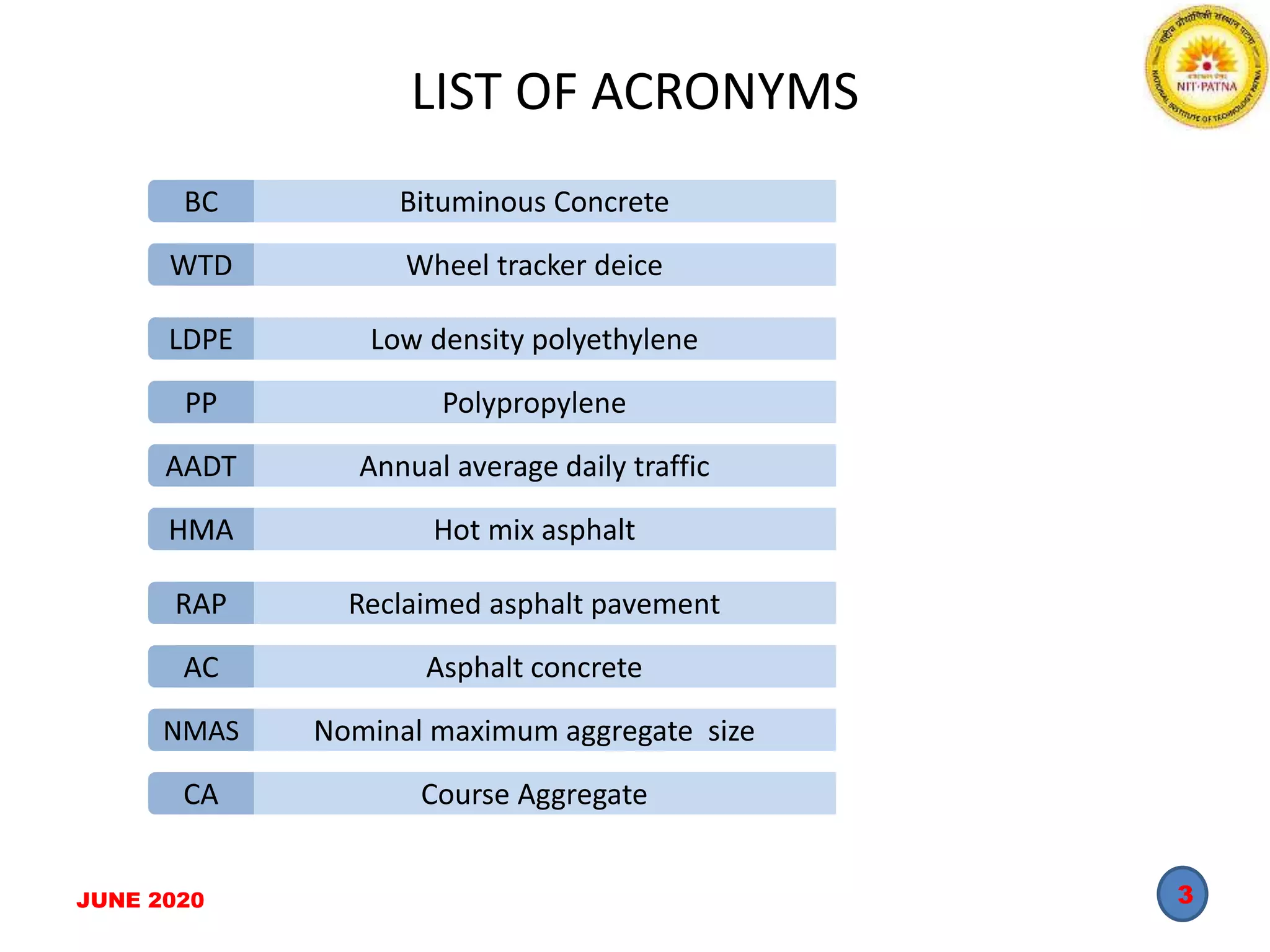

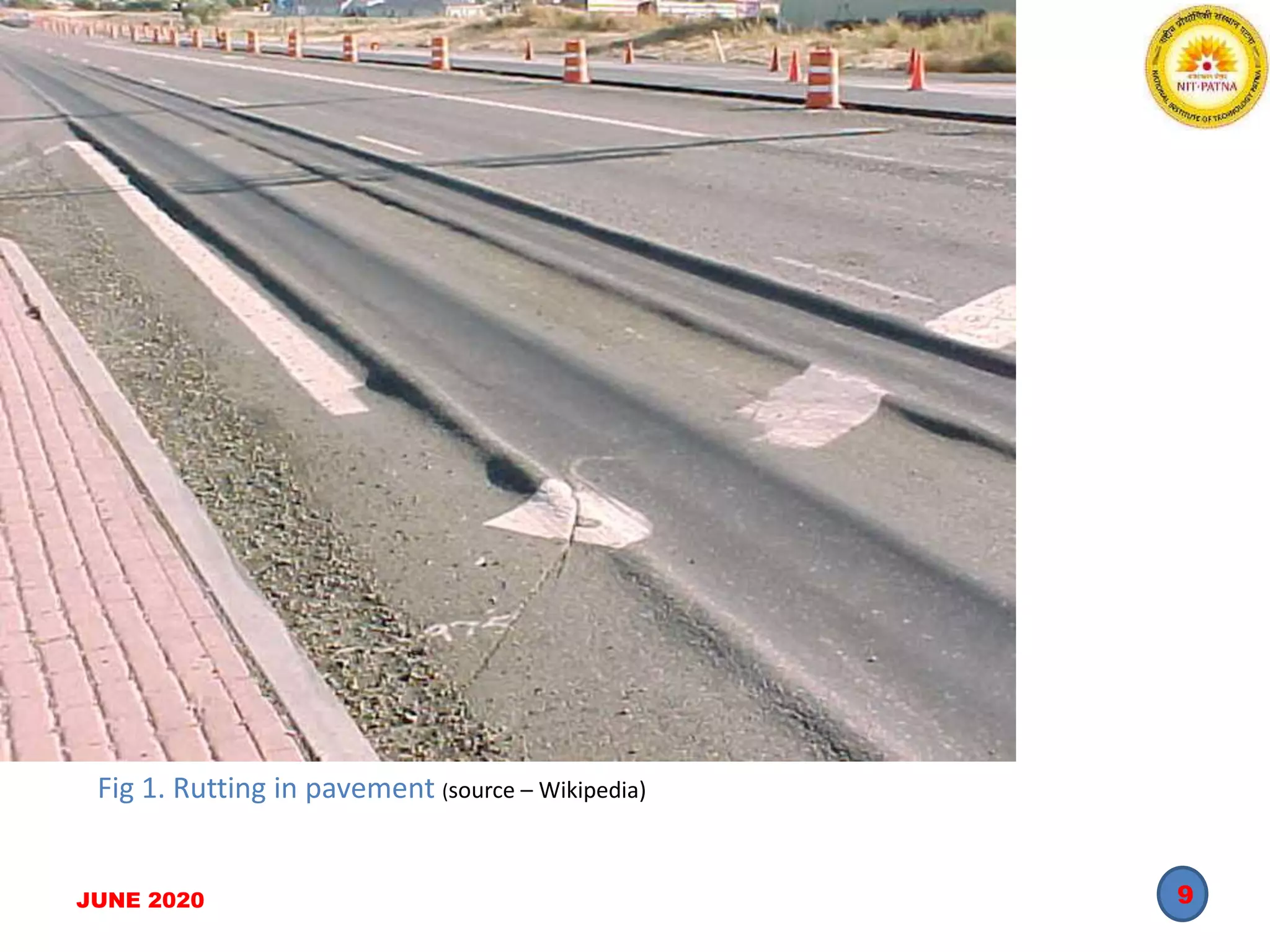

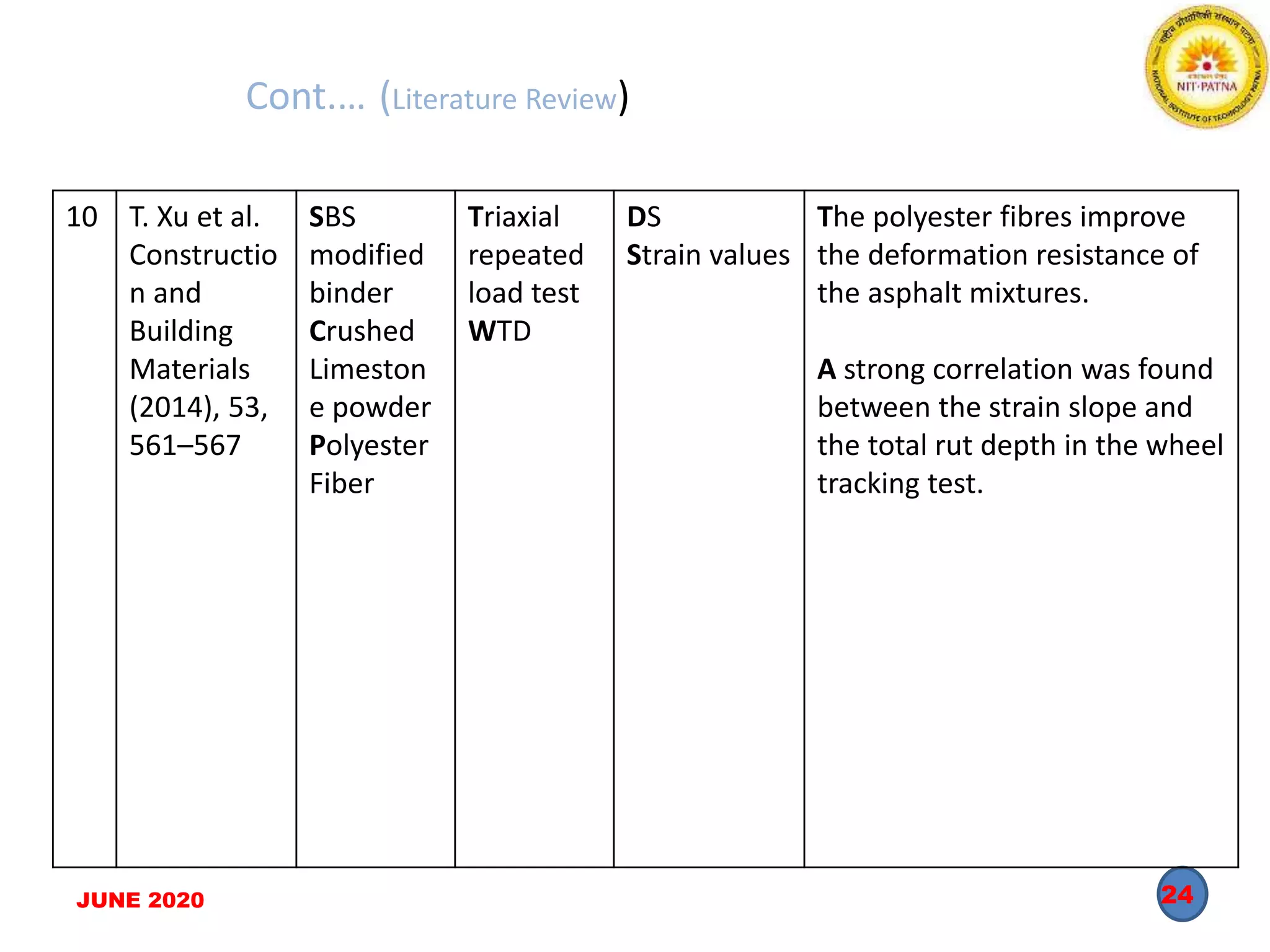

The document summarizes a study on rutting potential of bituminous mixes using a wheel tracker device. It includes an introduction describing the background and objectives of rutting in pavements. It then reviews 17 previous studies on factors affecting rutting like binder grade, aggregate type and size, and use of additives. The literature review establishes that softer binders, larger aggregate size and additives like polymers and waste plastics can improve rutting resistance.