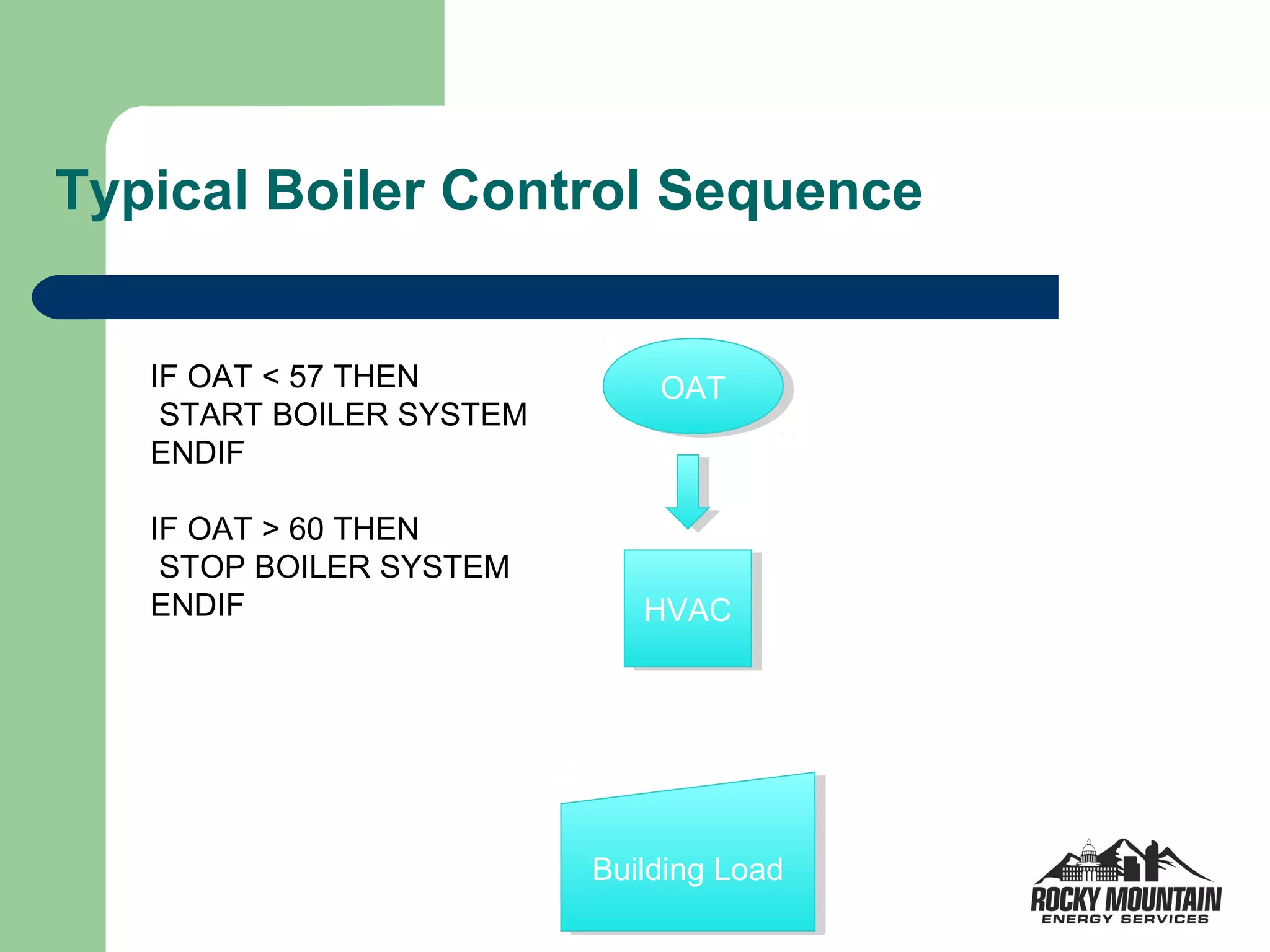

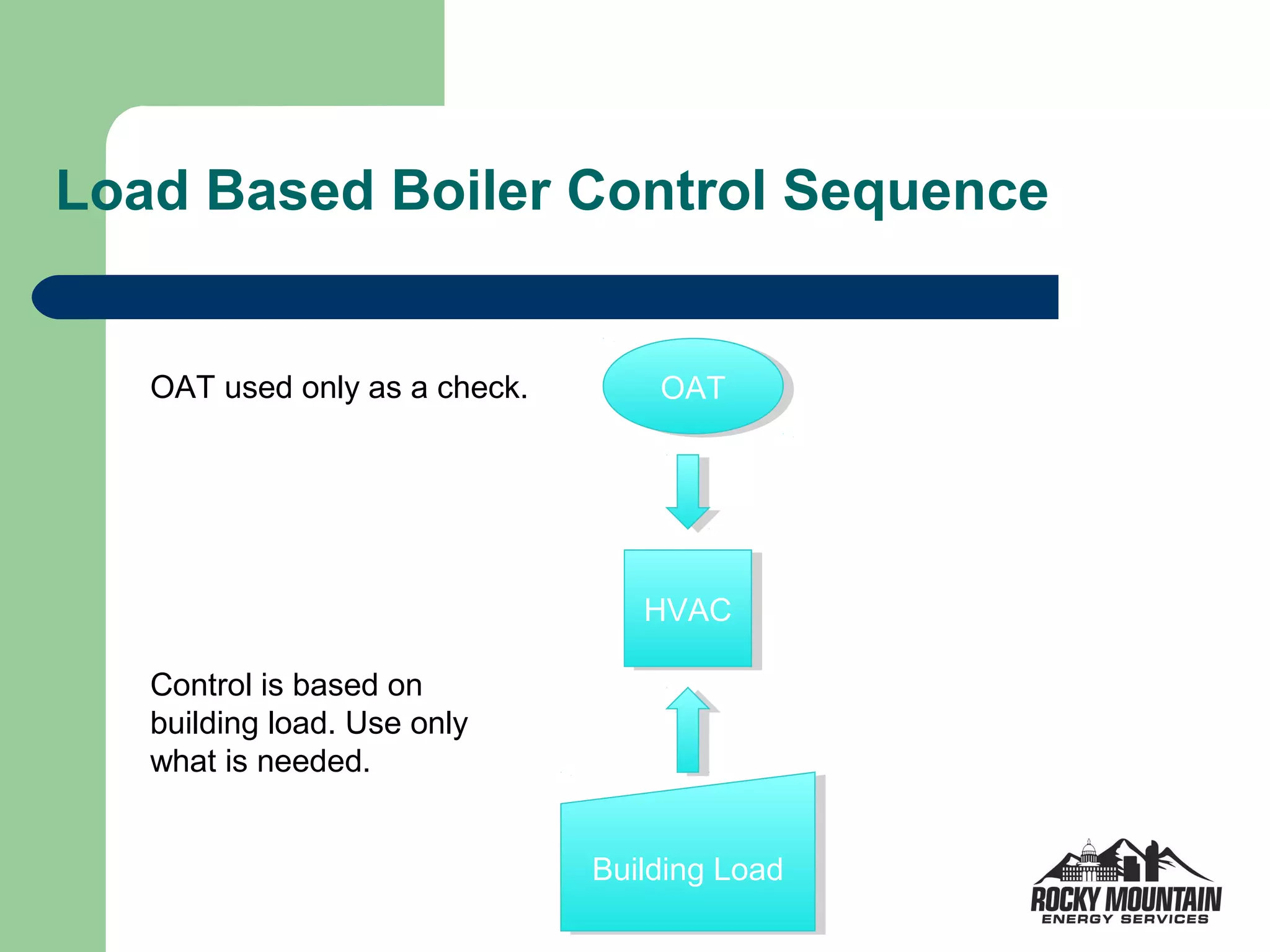

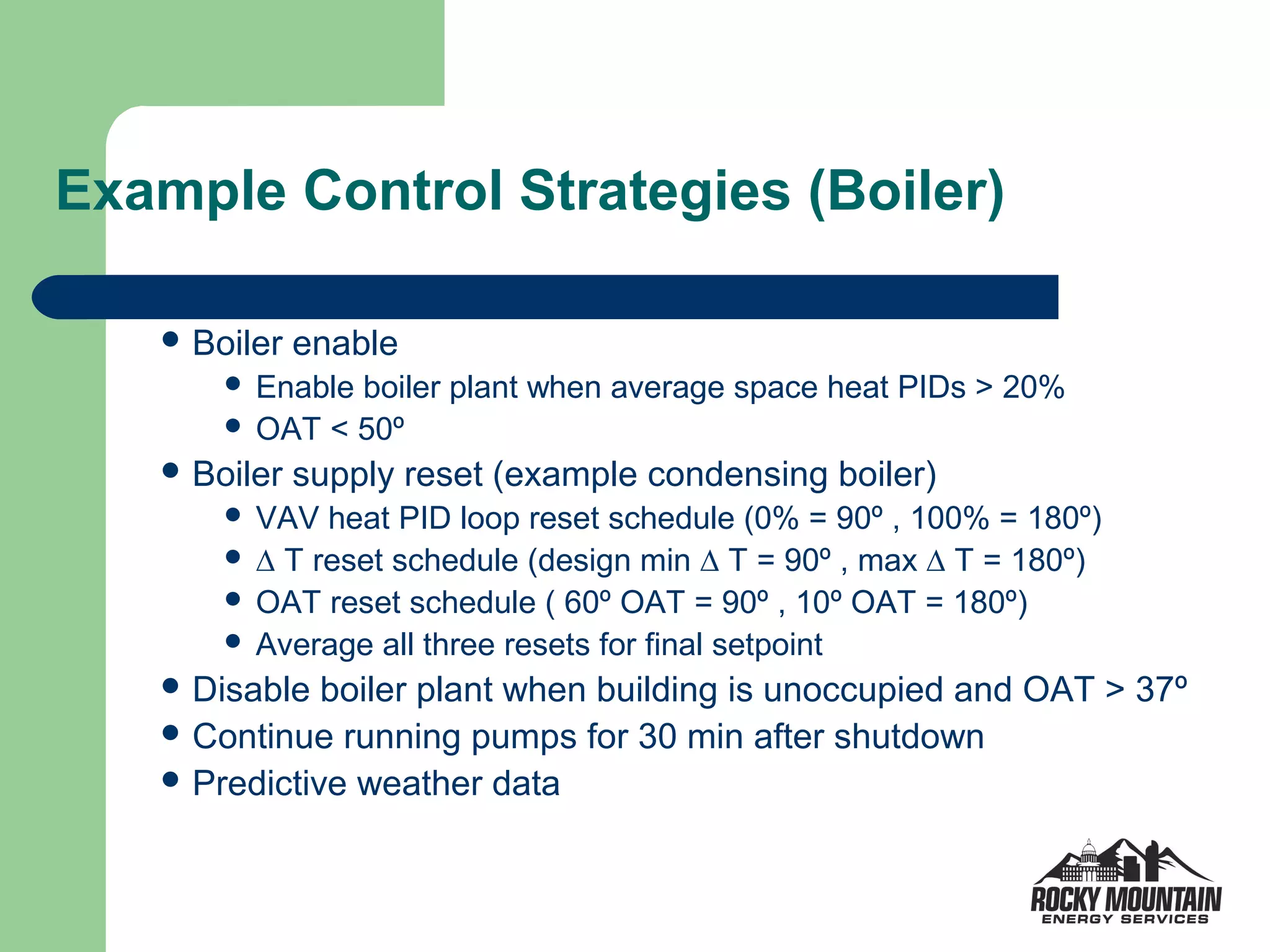

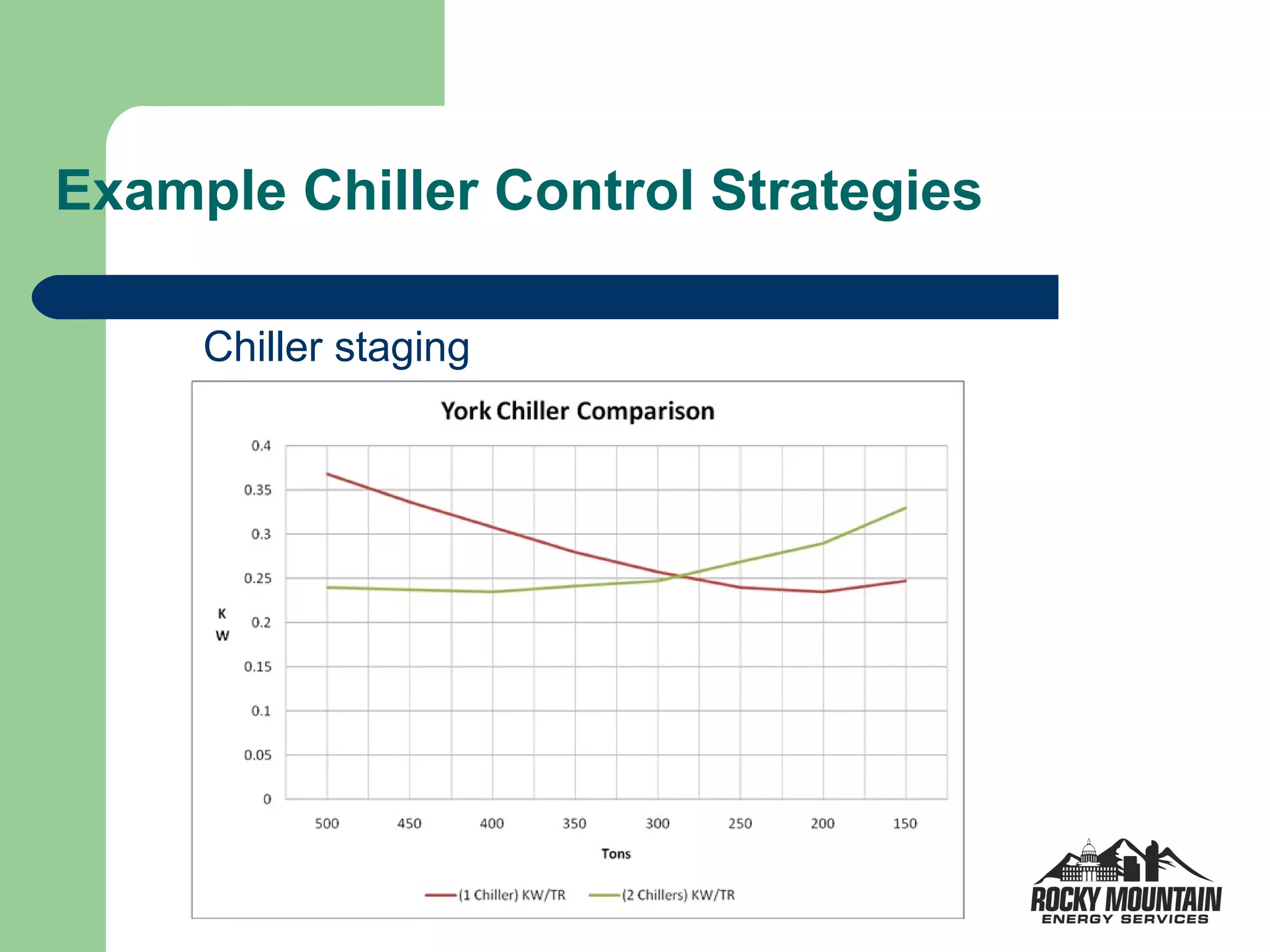

Rocky Mountain Energy Services (RMES) is a building automation company that specializes in load-based control strategies to optimize energy usage. RMES designs, installs, and programs building automation systems using KMC Controls products. They focus on fully utilizing control system data and implementing control strategies based on actual building load rather than outside air temperature alone. Example load-based control strategies presented for boilers, chillers, air handling units, and VAV boxes are aimed at reducing energy usage while maintaining occupant comfort. Case studies on past projects demonstrated energy savings of 20-47% through control optimization and retrofits.