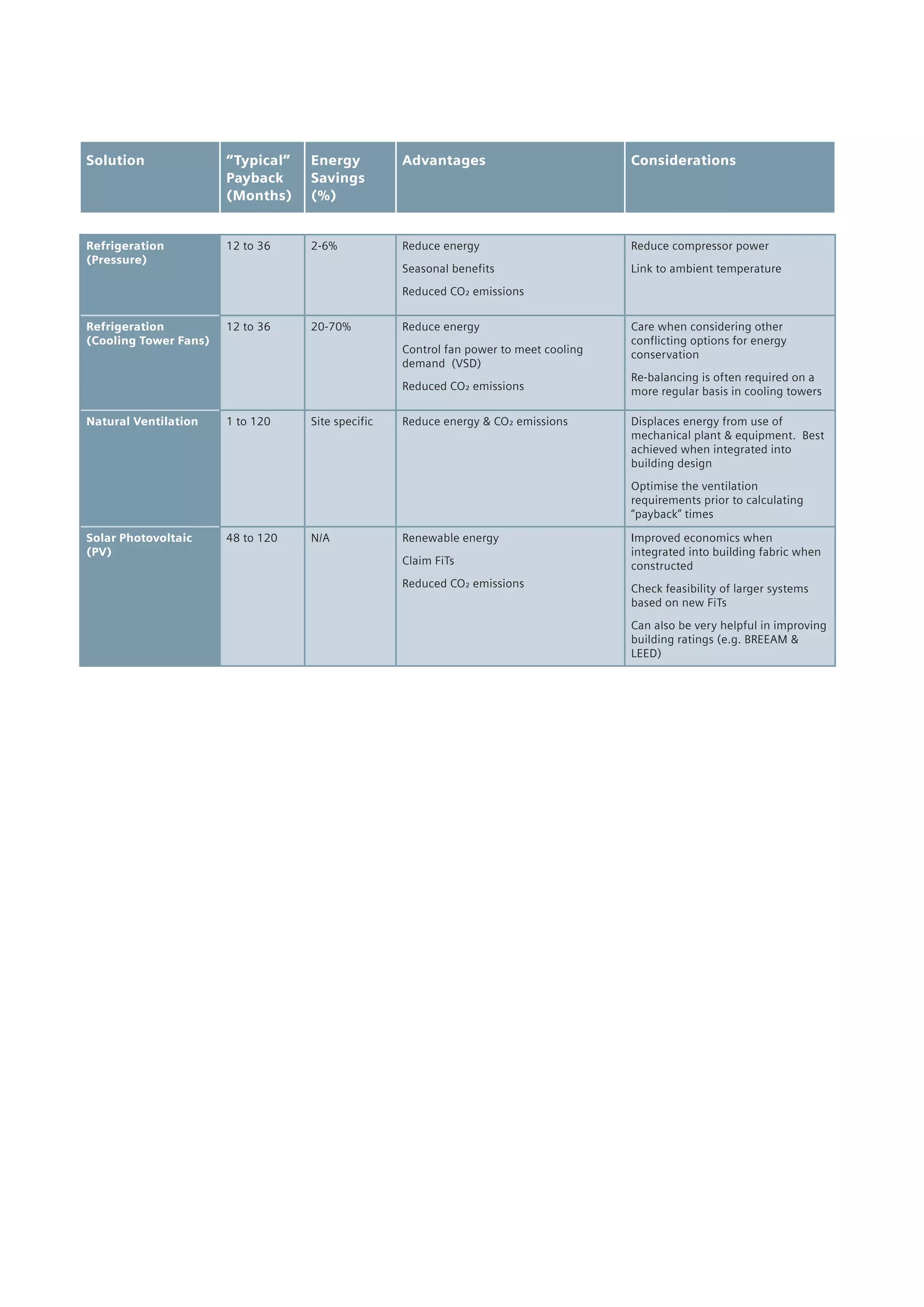

Automatic monitoring and targeting (aM&T) can identify opportunities to reduce energy consumption within 3 to 12 months and save 3-10% of total utility costs. It provides performance reporting and allows immediate identification of exceptional energy usage. Considerations include means for collecting data and having appropriate reporting processes.

Variable speed drives can pay back within 3 to 12 months while saving 20-70% of energy costs from smoother process control, longer equipment life, and other advantages. Ensuring motor compatibility and proper installation and maintenance is important.

Lighting upgrades like LEDs and high frequency fittings typically pay back within 1 to 3 years while saving 70-50% of energy. Considerations include environmental compatibility, color rendition, number

![Solution “Typical”

Payback

(Months)

Energy

Savings

(%)

Advantages Considerations

Automatic

Monitoring and

Targetting (aM&T)

3 to 12 3 - 10% of

total utility use

Highly useful for effective energy

management

Critical information for employee

engagement programmes

Can identify low, medium, high cost

opportunities for energy and utility

consumption

Can identify exceptional consumptions

immediately

High quality performance reporting

Need to consider means for

collecting data

Essential to have appropriate

reporting and processes

Level of sophistication tailored to

energy spend

Resource support considerations

High efficiency

motors

3 to 12 2 - 5% Improved intrinsic efficiency

Direct replacements for standard motors

Implement as part of a motor

management programme

Efficiency level IE2 is mandatory from

June 11

Not necessary for very light duty

applications (say less than 1000

hours per year)

May not be suitable for high torque

applications - e.g. Crushers in the

aggregates industry

Appropriate alignment (laser) should

be considered for direct drive

applications

Variable Speed drives

3 to 12 20-70% Smoother control of process - reduced

maintenance and improved reliability

Controlled starting and stopping

Longer system life

Different level of savings for Variable

Torque and Constant Torque

applications

Ensure that the motors are suitable

for VSD operation - esp. old or cheap

motors

May not be able to reduce the speed

greatly if high constant head

pressure is required

Correct installation and maintenance

is important

Lighting

LED’s 1 to 12 70% Higher lumens / Watt Consideration must be given to the

environment in which lamps are

being fitted

Colour rendition qualities need to be

considered

(Metal Halide)

High

Frequency

fittings

12 to 36 10-30% Integrate controls

Dimmable

Maximum savings available where

daylight savings to be made

(T5

Fluorescent)

12 to 36 10-50% Dimmable

Integrate controls

Higher number of fittings may be

required if retrofitting existing

Fluorescent lamp installation

High

Frequency

adapters

12 to 36 20-50% Reduced installation requirements

Energy savings similar to high frequency

fittings

Maintenance

May not be possible to retrofit to

older fittings

Controls

[including

constant light

control with

DALI,KNX etc]

12 to 48 30% Improved control of lighting

Reduced ‘lighting pollution’

Extend lamp life

A number of light fittings will not be

compatible with controls

Consideration should be given to

integrating lighting control to local

environment / process control

Enhanced

Automation Systems

12 to 48 2 -10% Operational efficiency improvements

Less labour intensive

Quality of product - consistent

Integrate data collection and energy

management functions into existing

automation systems](https://image.slidesharecdn.com/energyefficiency-wheretoinvest-170103204230/75/Energy-efficiency-where-to-invest-3-2048.jpg)