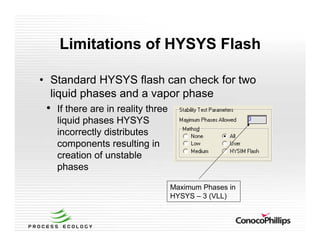

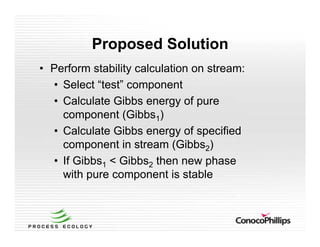

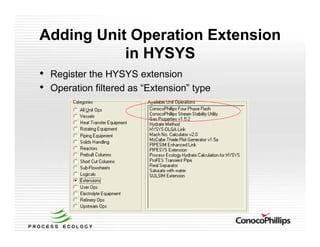

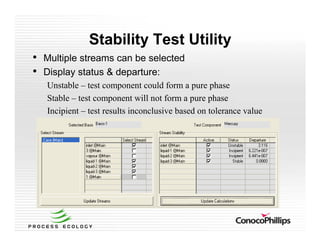

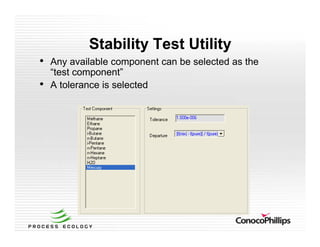

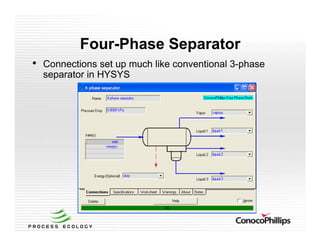

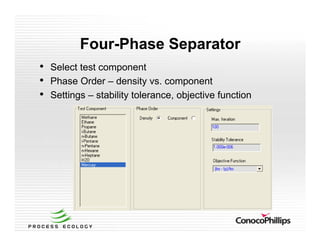

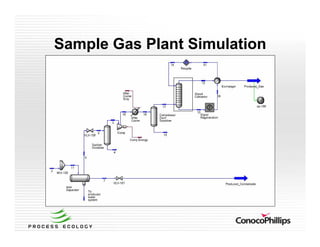

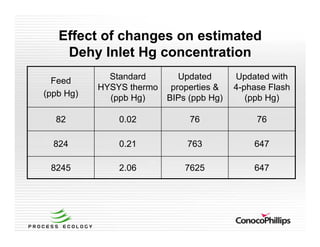

The document discusses the implementation of a 4-phase flash operation in HYSYS for detecting a third liquid phase in hydrocarbon simulations, addressing limitations of the existing flash capabilities. The proposed solution involves creating an extension to HYSYS that performs stability tests and allows for accurate phase separation detection in various industrial applications, particularly concerning mercury management. Key improvements include enhanced property modeling and solubility prediction to better simulate hydrocarbon systems with heavy fractions and immiscible components.