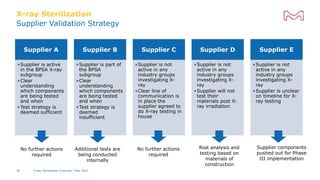

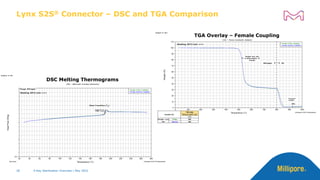

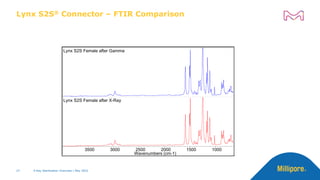

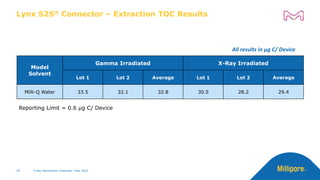

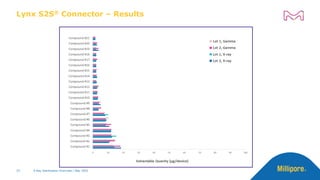

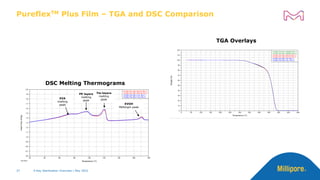

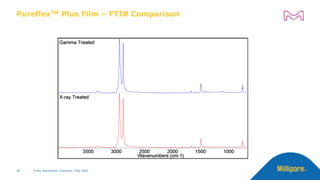

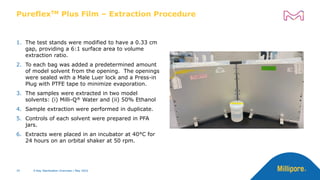

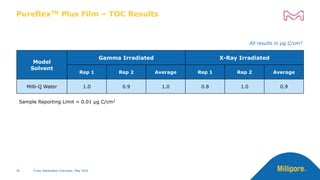

The document discusses testing done to qualify the use of x-ray sterilization for a Lynx S2S connector. Physical, chemical, and biological tests were performed on connectors that underwent either x-ray or gamma sterilization. Test results showed comparable extractable levels, thermal properties, and chromatographic profiles between the two sterilization methods. This provides evidence that x-ray sterilization is a suitable alternative to gamma sterilization for this connector.

![Lynx S2S® Connector – HPLC Chromatograms

214

nm

Absorbance

[AU]

-0.02

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.16

0.18

0.20

Time (minutes)

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00 16.00 17.00 18.00 19.00 20.00

X-Ray Lot 2

X-Ray Lot 1

Gamma Lot 2

Gamma Lot 1

Water Blank

214

nm

Absorbance

[AU]

-0.02

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.16

0.18

0.20

Time (minutes)

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00 16.00 17.00 18.00 19.00 20.00

X-Ray Lot 2

X-Ray Lot 1

Gamma Lot 2

Gamma Lot 1

50% EtOH Blank

Water Extracts

50% Ethanol Extracts

X-Ray Sterilization Overview | May 2022

30](https://image.slidesharecdn.com/webinarpresentationrisk-basedqualificationofx-raysterilizationmay05final-220506152255-ab5d3294/85/Risk-Based-Qualification-of-X-Ray-Sterilization-for-Single-Use-Systems-30-320.jpg)

![214

nm

Absorbance

[AU]

0.0000

0.0096

0.0192

0.0288

0.0384

0.0480

0.0576

0.0672

0.0768

0.0864

0.0960

Time (minutes)

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00 16.00 17.00 18.00 19.00 20.00

PureflexTM Plus Film – HPLC Chromatograms

41

X-Ray PureFlex Plus Rep-2

X-Ray PureFlex Plus Rep-1

Gamma PureFlex Plus Rep-2

Gamma PureFlex Plus Rep-1

Water Control

214

nm

Absorbance

[AU]

-0.025

0.000

0.025

0.050

0.075

0.100

0.125

0.150

0.175

0.200

0.225

0.250

Time (minutes)

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00 16.00 17.00 18.00 19.00 20.00

X-Ray PureFlex Plus Rep-2

X-Ray PureFlex Plus Rep-1

Gamma PureFlex Plus Rep-2

Gamma PureFlex Plus Rep-1

50% Ethanol Control

Water Extracts

50% Ethanol Extracts

41 X-Ray Sterilization Overview | May 2022

X-Ray Sterilization Overview | May 2022](https://image.slidesharecdn.com/webinarpresentationrisk-basedqualificationofx-raysterilizationmay05final-220506152255-ab5d3294/85/Risk-Based-Qualification-of-X-Ray-Sterilization-for-Single-Use-Systems-41-320.jpg)