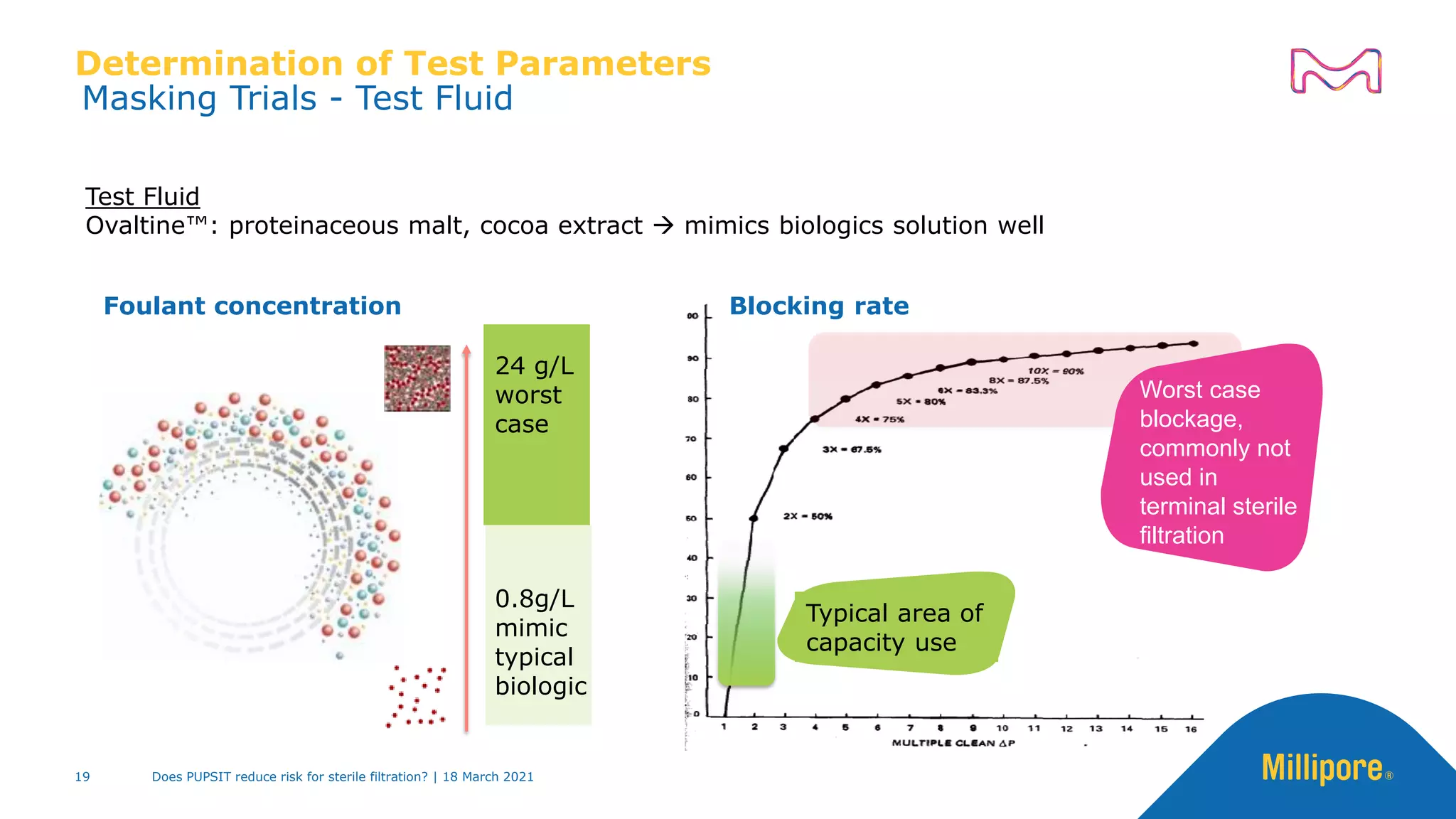

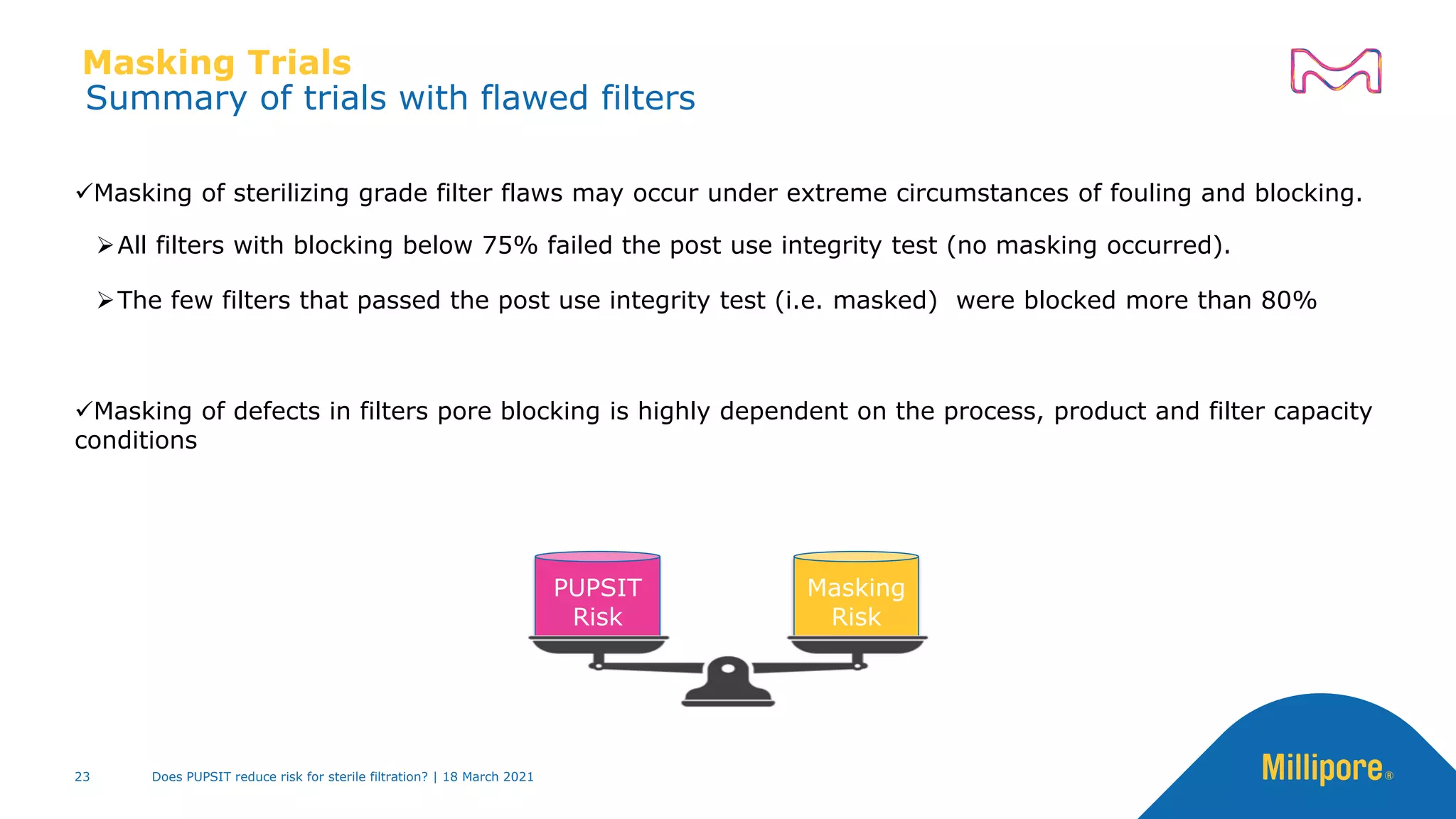

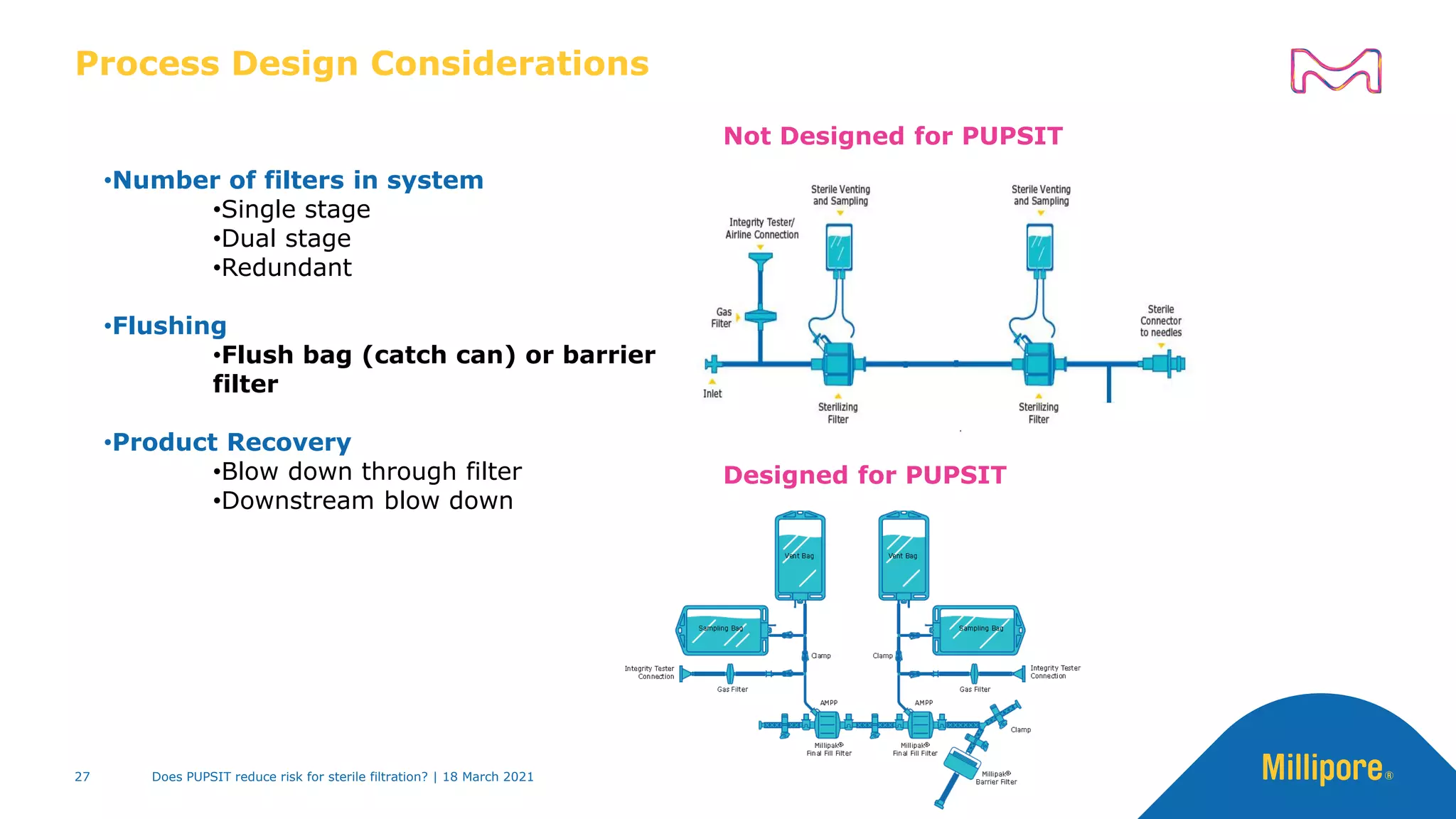

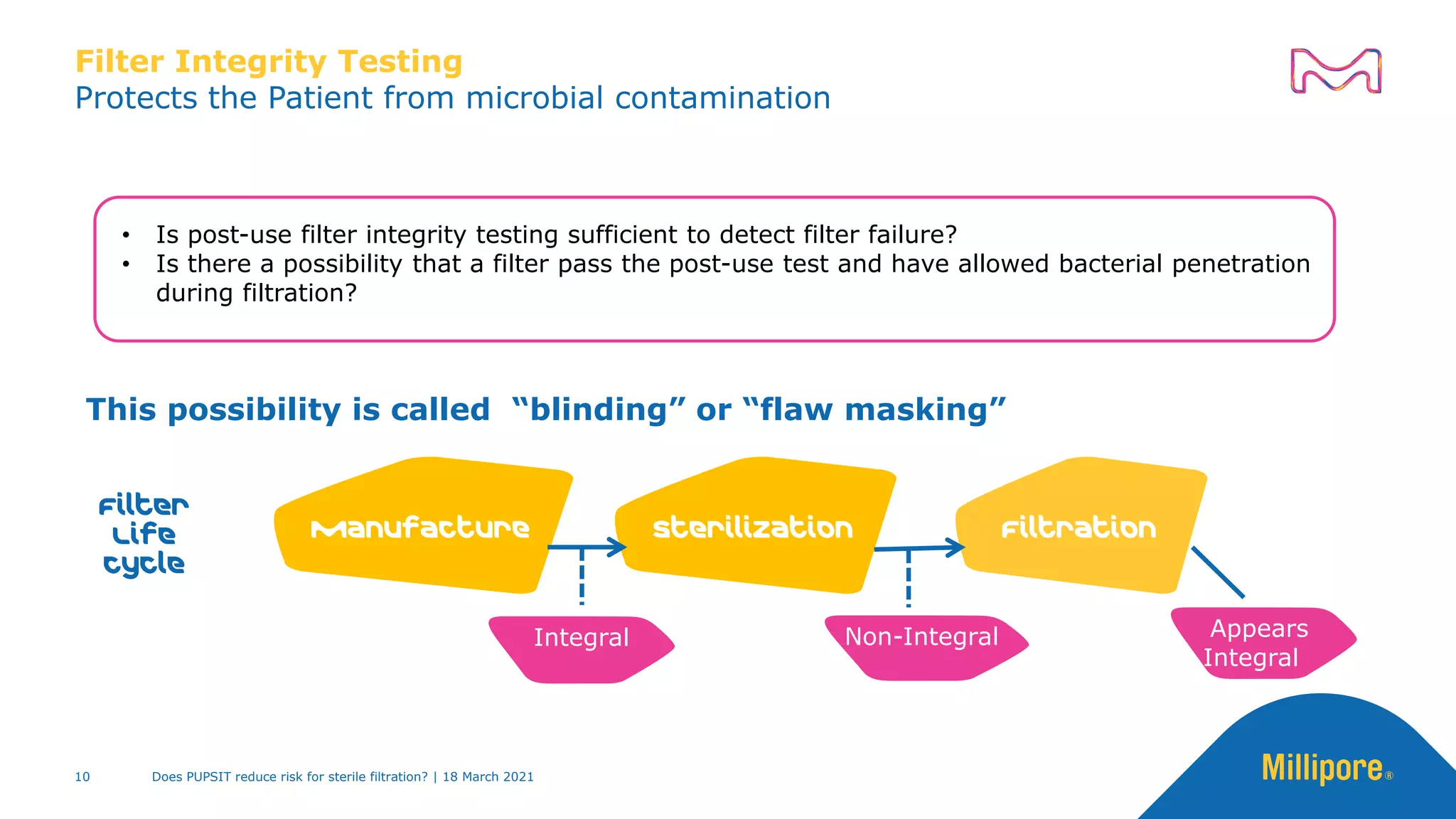

This presentation discusses pre-use post-sterilization integrity testing (PUPSIT) of sterile filters. It provides background on regulatory guidance for integrity testing critical filters before and after use. Masking studies were conducted where flawed filters were exposed to blocking solutions, and in some cases the flaws were able to mask and pass post-use integrity testing. The risk of masking was found to be highly dependent on process conditions like blocking rate and solution concentration. The presentation discusses considerations for final filtration assembly design to enable PUPSIT like using redundant filters and multi-purpose ports. It addresses challenges with maintaining sterility and pressure during PUPSIT.

![Regulatory -

EU GMP Annex 1 draft, 2020:

Integrity test before use and

post-use

“…[PUPSIT] may not always

be possible after sterilization due

to process constraints (e.g. the

filtration of very small volumes of

solution). In these cases, an

alternative approach may be taken

as long as a thorough risk

assessment has been performed

and compliance is achieved by the

implementation of appropriate

controls to navigate any risk of

non-sterility.

Industry -

PDA Technical Report 26:

“Integrity testing alone is

insufficient to assure the sterility

of the filtrate. At least two other

elements must be in place:

The production controls and

quality assurance systems

used by the filter

manufacturer ...

And the validation studies

used to show that a particular

combination of product,

processing conditions and

sterilizing grade filter will meet

the requirements of the

bacterial challenge test.”

Establish minimum

Bubble Point

Membrane manufacturing

and testing

Device manufacturing

and testing

Validation studies

End-user integrity test

Integrity test of "sterilizing filter” alone is insufficient

Evolving Perspective – Sterility Assurance

Does PUPSIT reduce risk for sterile filtration? | 18 March 2021

12](https://image.slidesharecdn.com/pupsitwebinarfinalmarch18-210319092119/75/Does-PUPSIT-Reduce-Risk-for-Sterile-Filtration-12-2048.jpg)