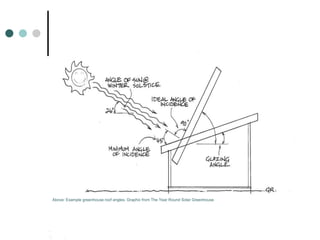

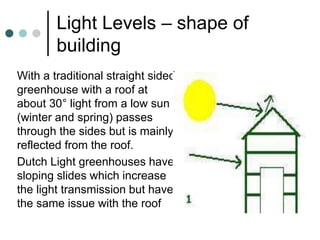

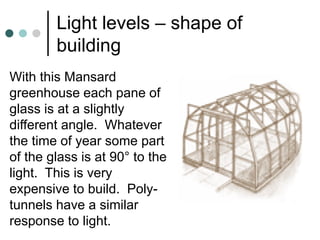

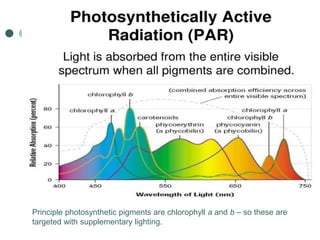

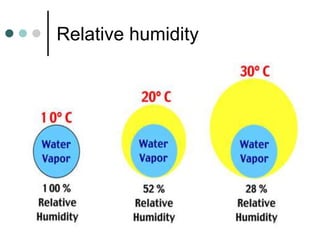

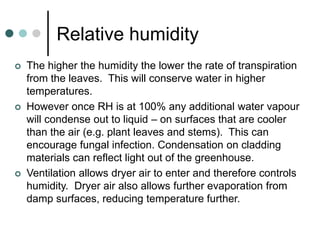

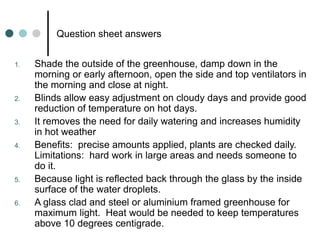

This document discusses controlling the environment in protected structures like greenhouses. It describes factors that affect light levels, such as the shape, orientation, and materials of the structure. It also discusses maintaining temperature through heating, cooling methods like ventilation and evaporation, and shading. The document covers manipulating relative humidity through damping down and ventilation. It describes irrigation methods like manual watering and automated drip systems. Finally, it discusses manipulating light levels with supplementary lighting and shading tools like blinds.