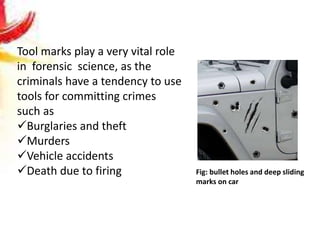

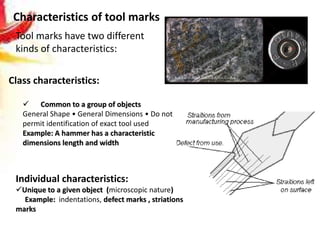

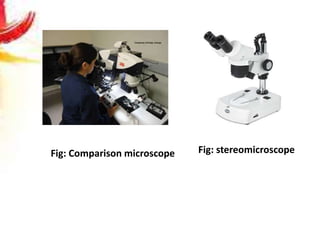

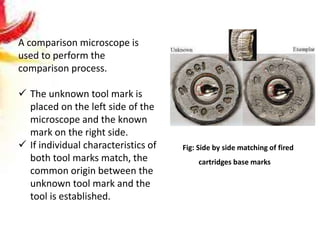

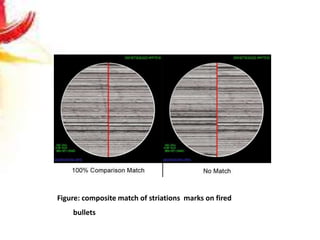

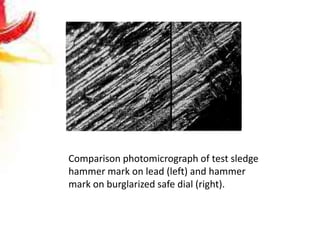

Tool marks evidence plays an important role in forensic science. Tool marks are impressions or marks left on surfaces by tools and can be used to identify the specific tool that made the mark. There are different types of tool marks such as impressions, abrasions, cuts, and drill holes. Tool marks contain both class characteristics common to groups of tools and unique individual characteristics. Tool marks are collected using methods like photography, casting, and test marks. Examiners compare both class and individual characteristics of tool marks using various techniques like microscopy and superimposition to determine if two marks have a common origin.