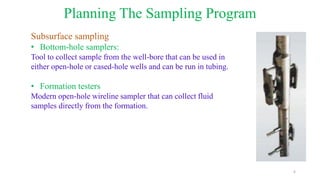

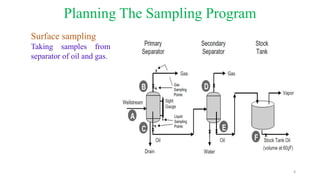

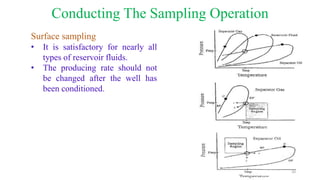

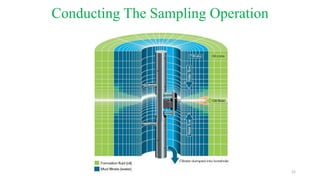

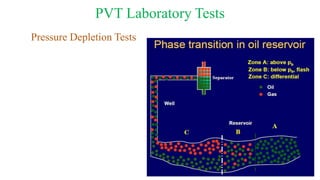

This document outlines the steps for planning and conducting reservoir fluid sampling operations. It discusses factors that influence planning such as reservoir fluid type and well conditions. It describes various sampling methods including subsurface, surface, and wellhead sampling. The document also covers preparing the well for sampling, including conditioning periods and measurements. Key steps are selecting the appropriate sampling tool and point, and ensuring samples are representative of reservoir fluids and brought to PVT laboratories for detailed analysis.