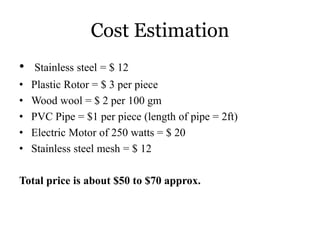

The document describes the design and construction of a small-scale cooling tower for a laboratory. It uses wood wool to lower the temperature of hot water poured in from the top, as the water passes through layers of wood wool on its way to the outlet at the bottom. A rotating plastic fan helps move the water through the tower. Materials used include stainless steel, wood wool, plastic, and PVC pipes. The total estimated cost is between $50-$70.