The document outlines the process of concrete mix design, emphasizing the significance of proportions of cement, sand, coarse aggregate, and water on the strength and durability of concrete. It details various IS codes governing concrete mix design, including IS 456:2000 and IS 10262:2019, providing guidelines on achieving specific workability and strength requirements through systematic mix proportions and trial mixes. Additionally, it presents calculation methods for determining water-cement ratios, cement and aggregate contents, and the overall mix design process to ensure economical and structurally adequate concrete.

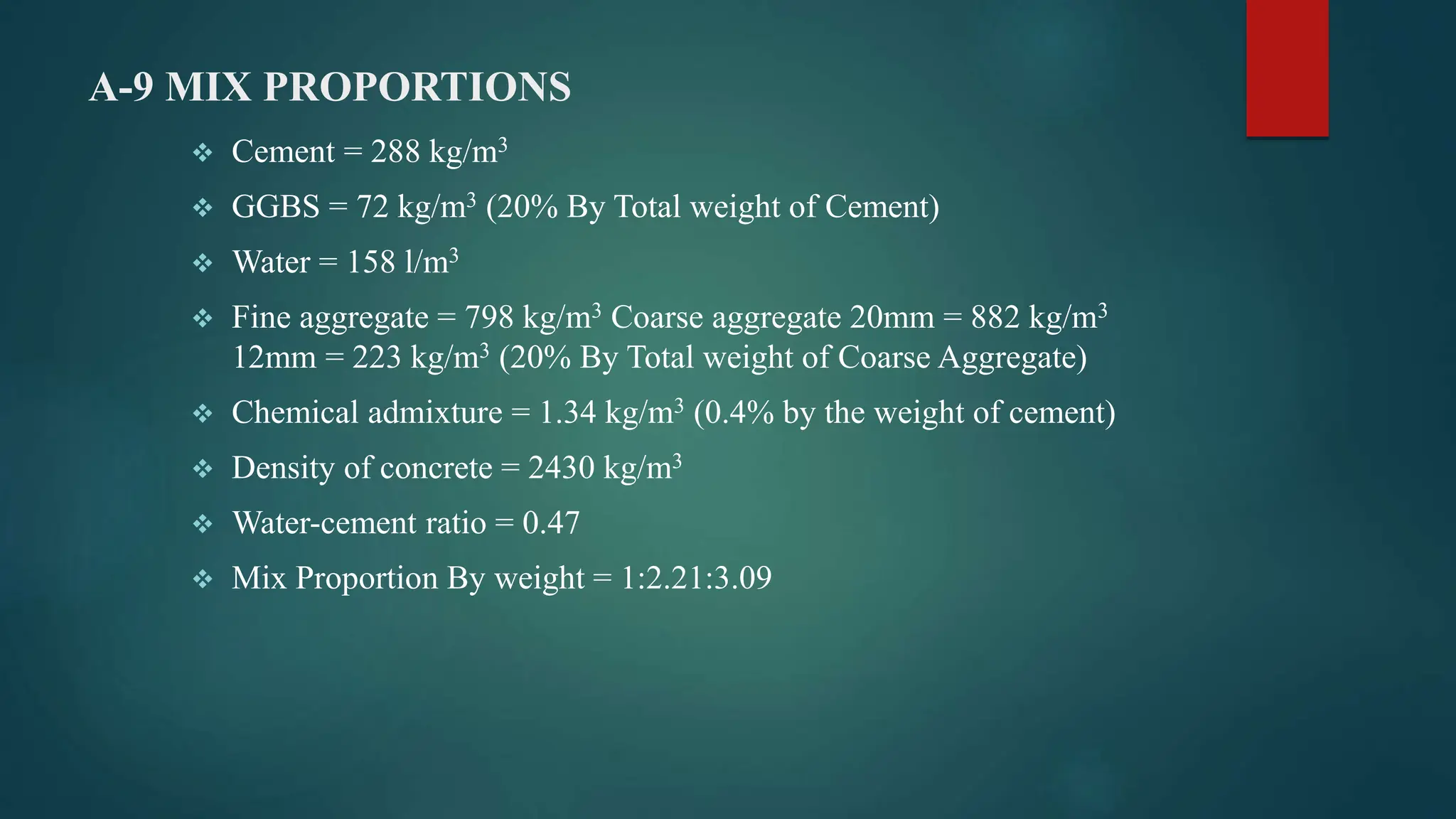

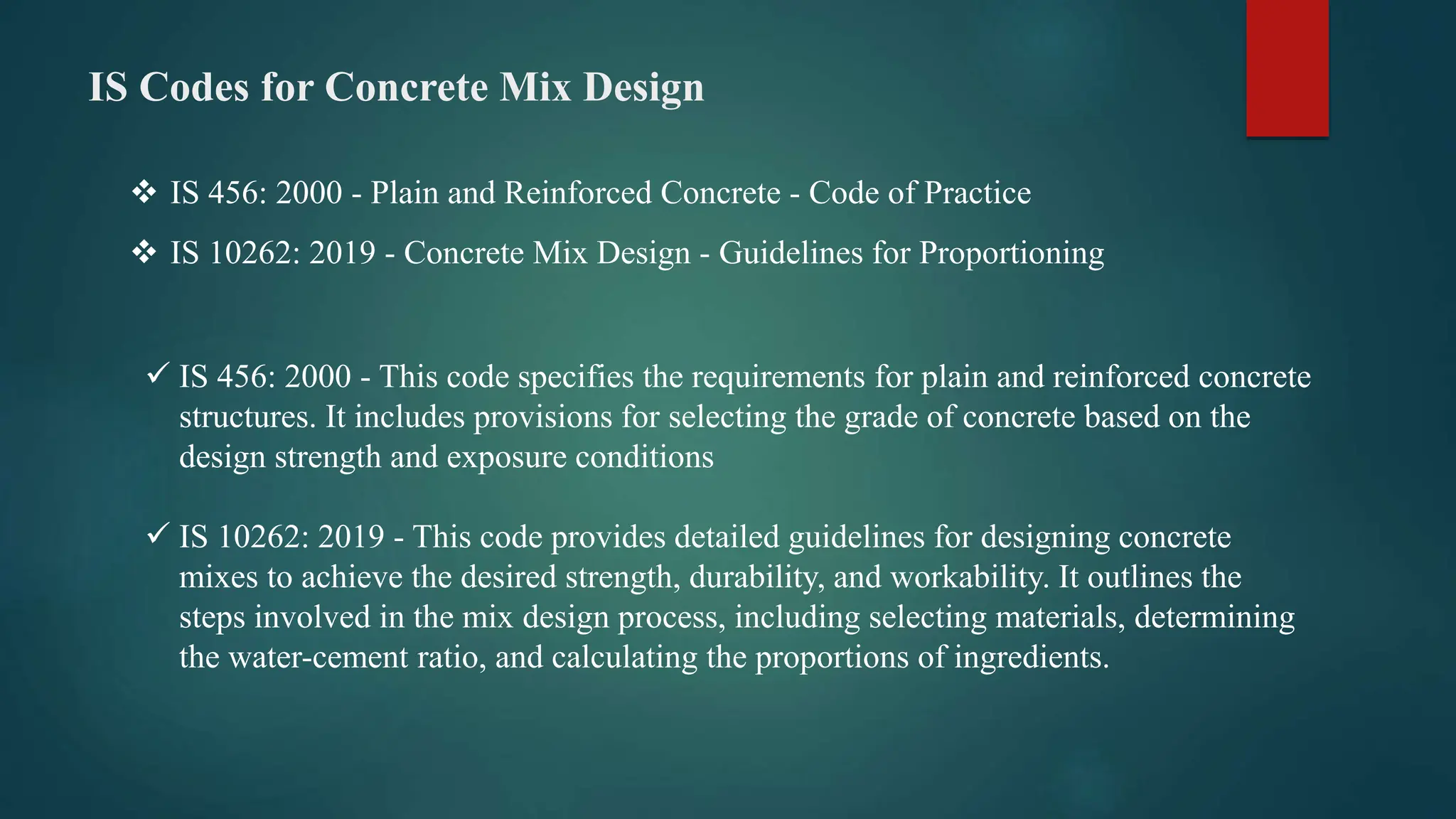

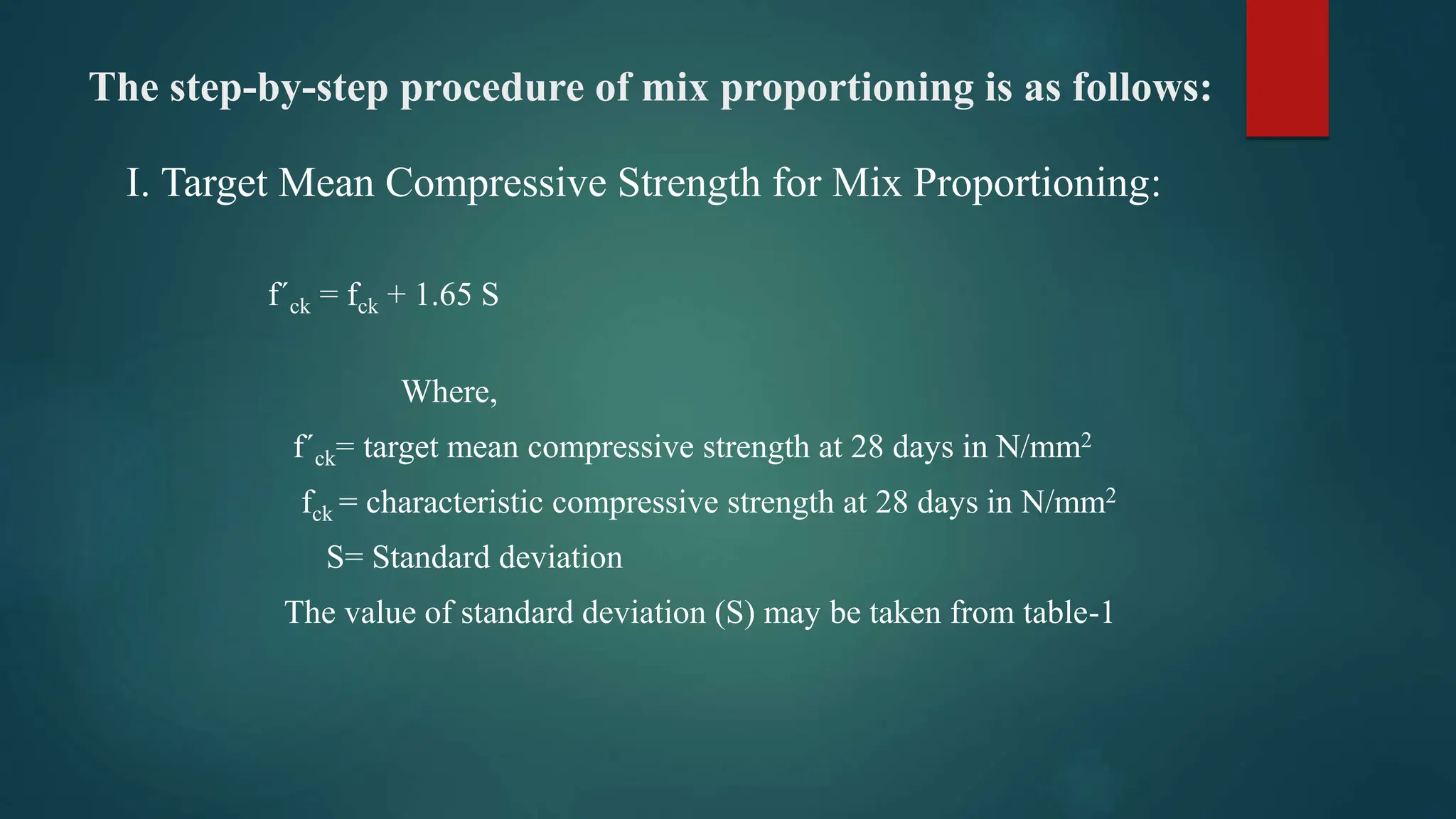

![Table No. 3 : Maximum Water Content Per Cubic Metre Of Concrete For

Nominal Size Of Aggregate [for slump 25 to 50 mm]

Use of water reducing admixture: If use of chemical water reducing

admixture is permitted for the job in hand in proportioning of the mix,

reduction in assumed water content shall be made depending on the type of

admixture. Water reducing admixtures will usually decrease water content

by 5 to 10% and superplasticisers decrease water content by 20% and

above at appropriate dosages.

Sr. No. Nominal Maximum Size of

Aggregate (mm)

Maximum water content (kg)

1 10 208

2 20 186

3 40 165](https://image.slidesharecdn.com/uplod-240430120706-d74fae0a/75/Concrete-Mix-Design-by-IS-Code-Method-is-code-method-uplod-pptx-14-2048.jpg)

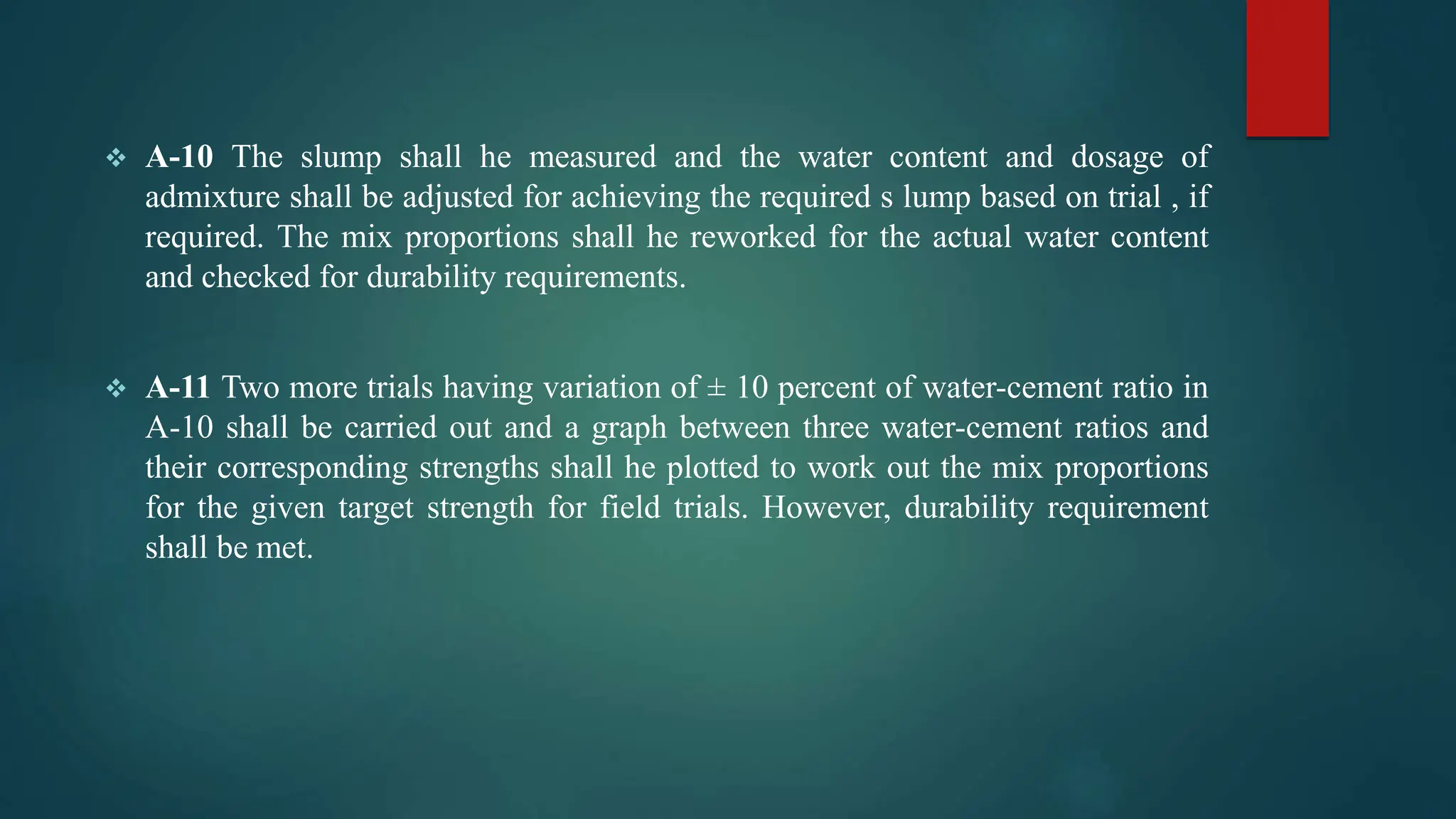

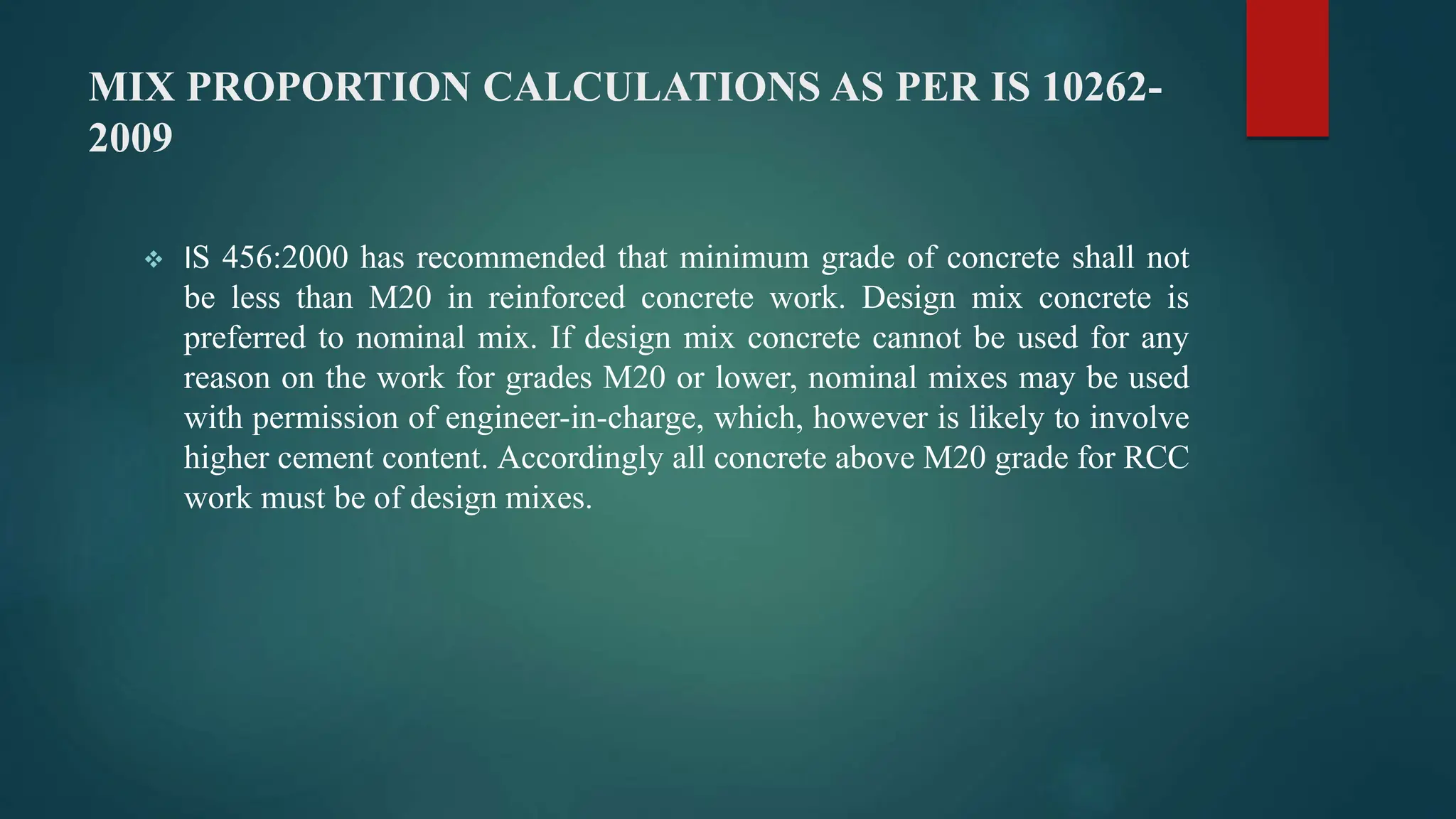

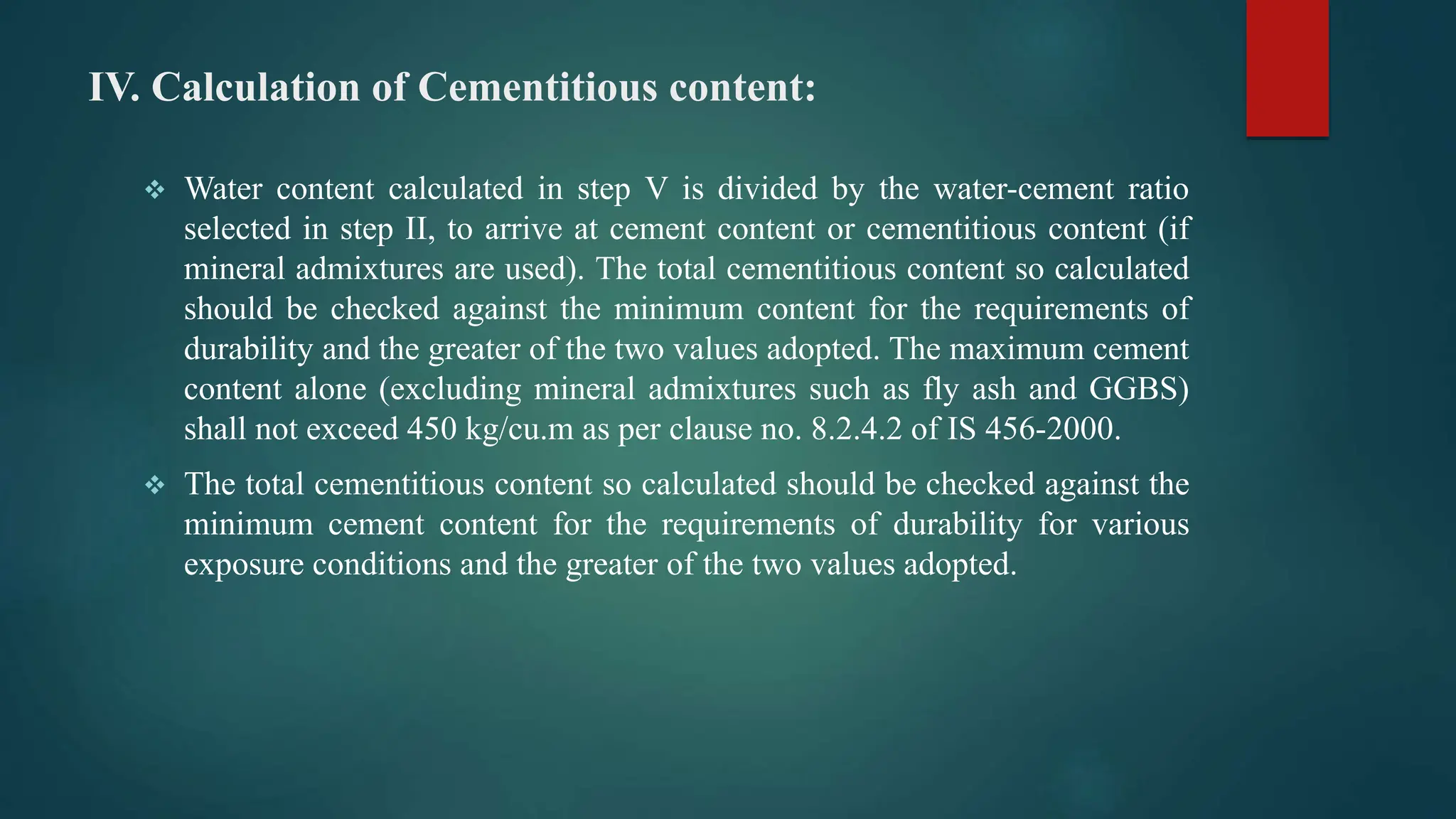

![Table no:5-Volume of course aggregate per unit volume of total

aggregate for different zones of fine aggregate

[for w/c = 0.50]

Volumes are based on Aggregates in Saturated Surface Dry condition

Note: Volume coarse aggregate per unit volume of total aggregate needs to

be changed at the rate of -/+ 0.01 for every ±0.05 change in water-cement

ratio

Sr. No. Nominal maximum

size of

aggregates(mm)

Volume of course aggregate per unit volume of total

aggregate for different zone of fine aggregate

Zone-IV Zone-III Zone-II Zone-I

1 10 0.50 0.48 0.46 0.44

2 20 0.66 0.64 0.64 0.60

3 40 0.75 0.73 0.71 0.69](https://image.slidesharecdn.com/uplod-240430120706-d74fae0a/75/Concrete-Mix-Design-by-IS-Code-Method-is-code-method-uplod-pptx-17-2048.jpg)

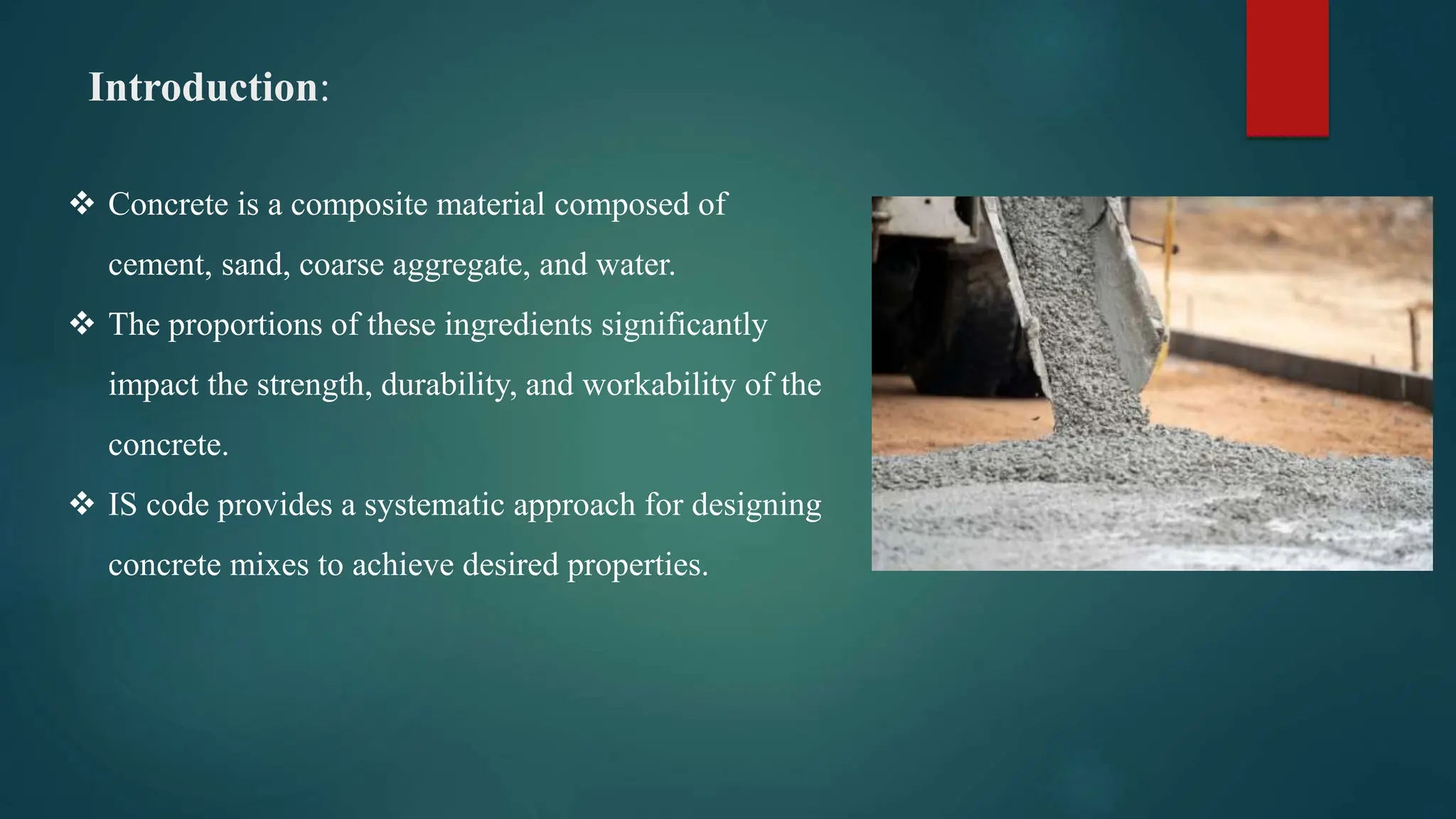

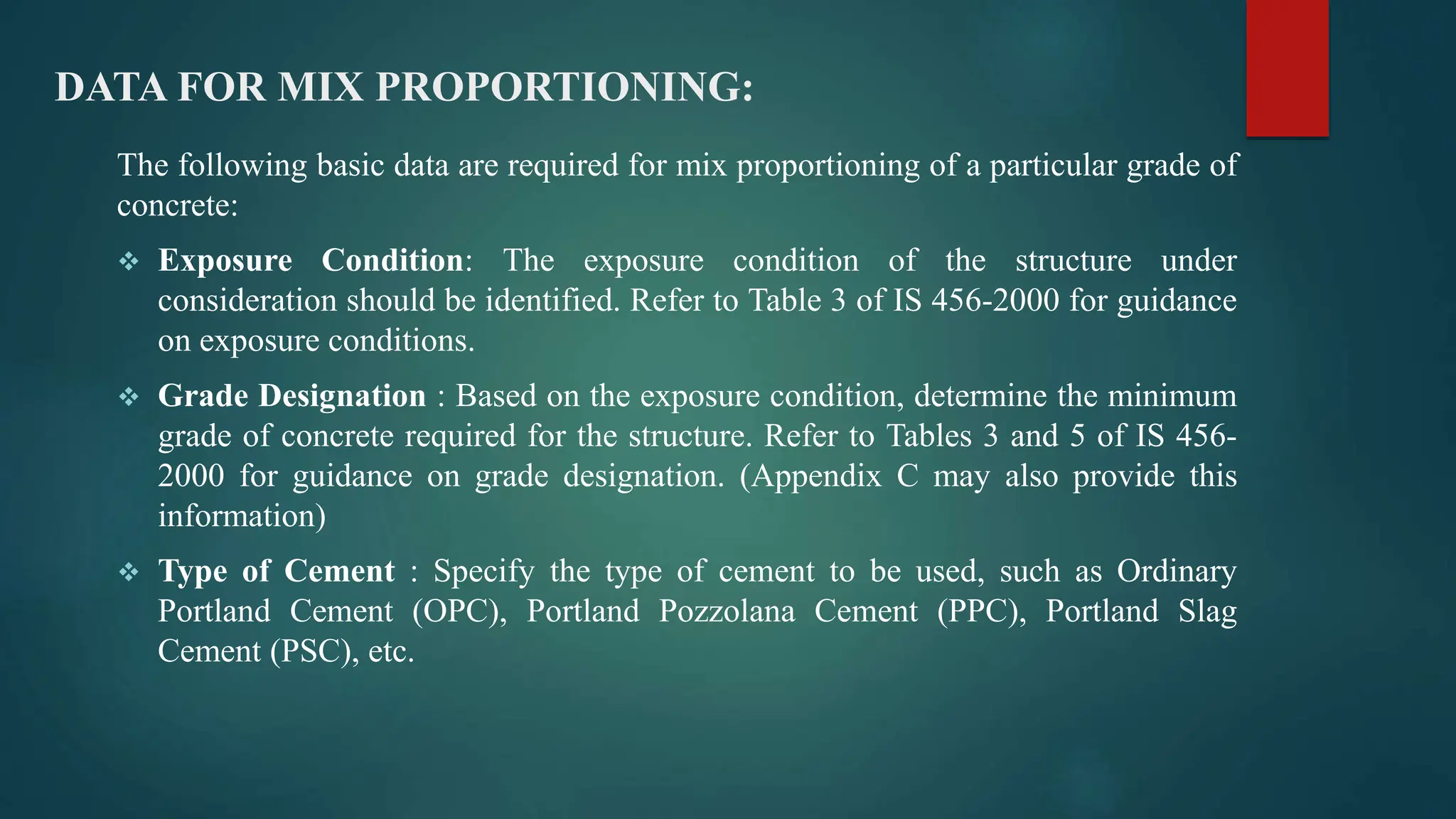

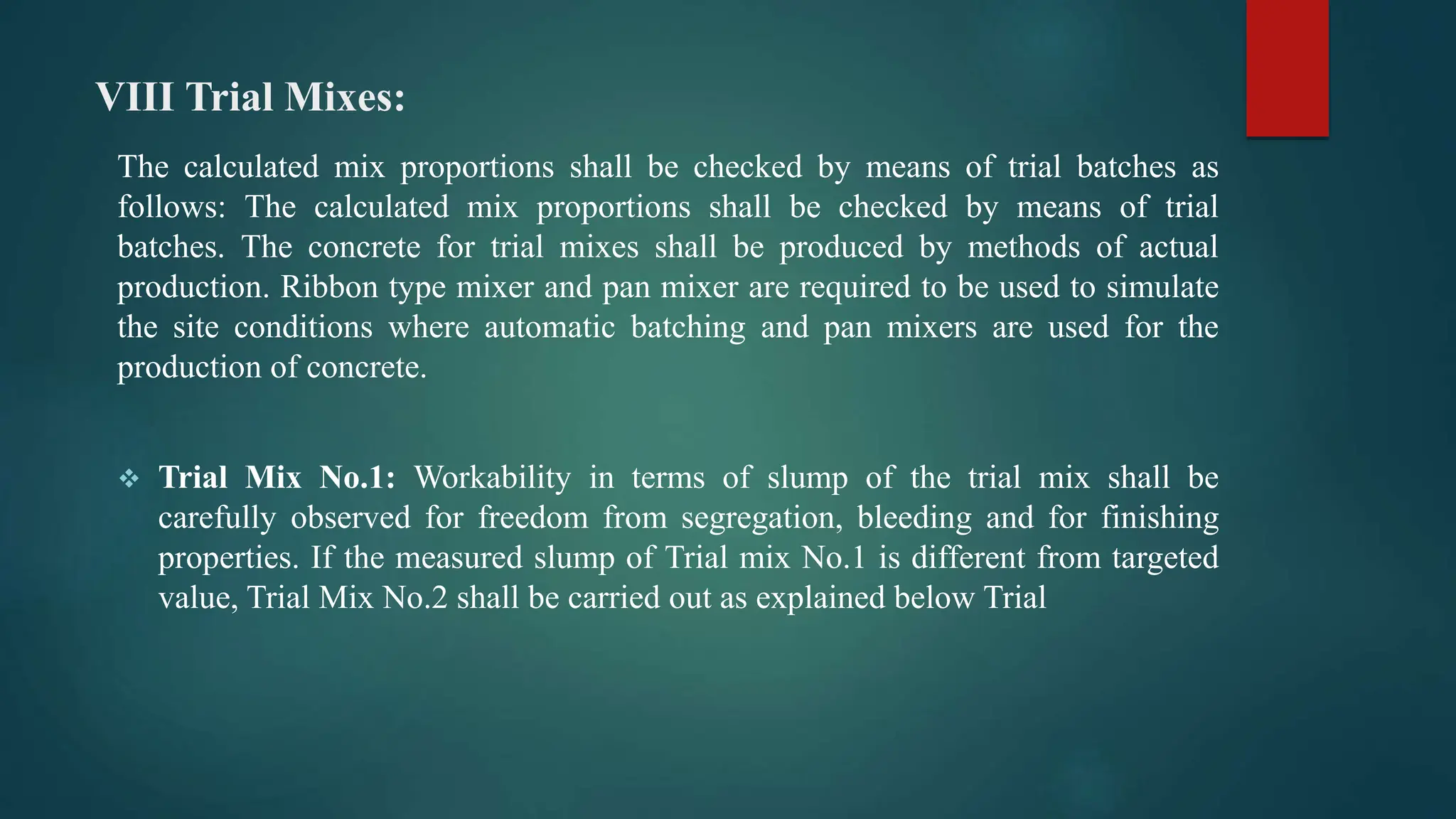

![A-4 SELECTION OF WATER•CEMENT RATIO

Adopted maximum water-cement ratio = 0.44. From the Table 5 of IS 456 for Very

severe Exposure maximum Water Cement Ratio is 0.45 0.44 < 0.45 Hence ok.

A-5 SELECTION OF WATER CONTENT

From Table 2 of IS 10262:2009, maximum water content for 20 mm aggregate =

186 litre (for 25 to 50 mm slump range) Estimated water content for 100 mm

slump = 186+ (6/186) = 197 litre.

(Note: If Super plasticizer is used, the water content can be reduced upto 20% and

above.)

Based on trials with Super plasticizer water content reduction of 20% has been

achieved, Hence the arrived water content = 197-[197 x (20/100)] = 158 litre.](https://image.slidesharecdn.com/uplod-240430120706-d74fae0a/75/Concrete-Mix-Design-by-IS-Code-Method-is-code-method-uplod-pptx-25-2048.jpg)

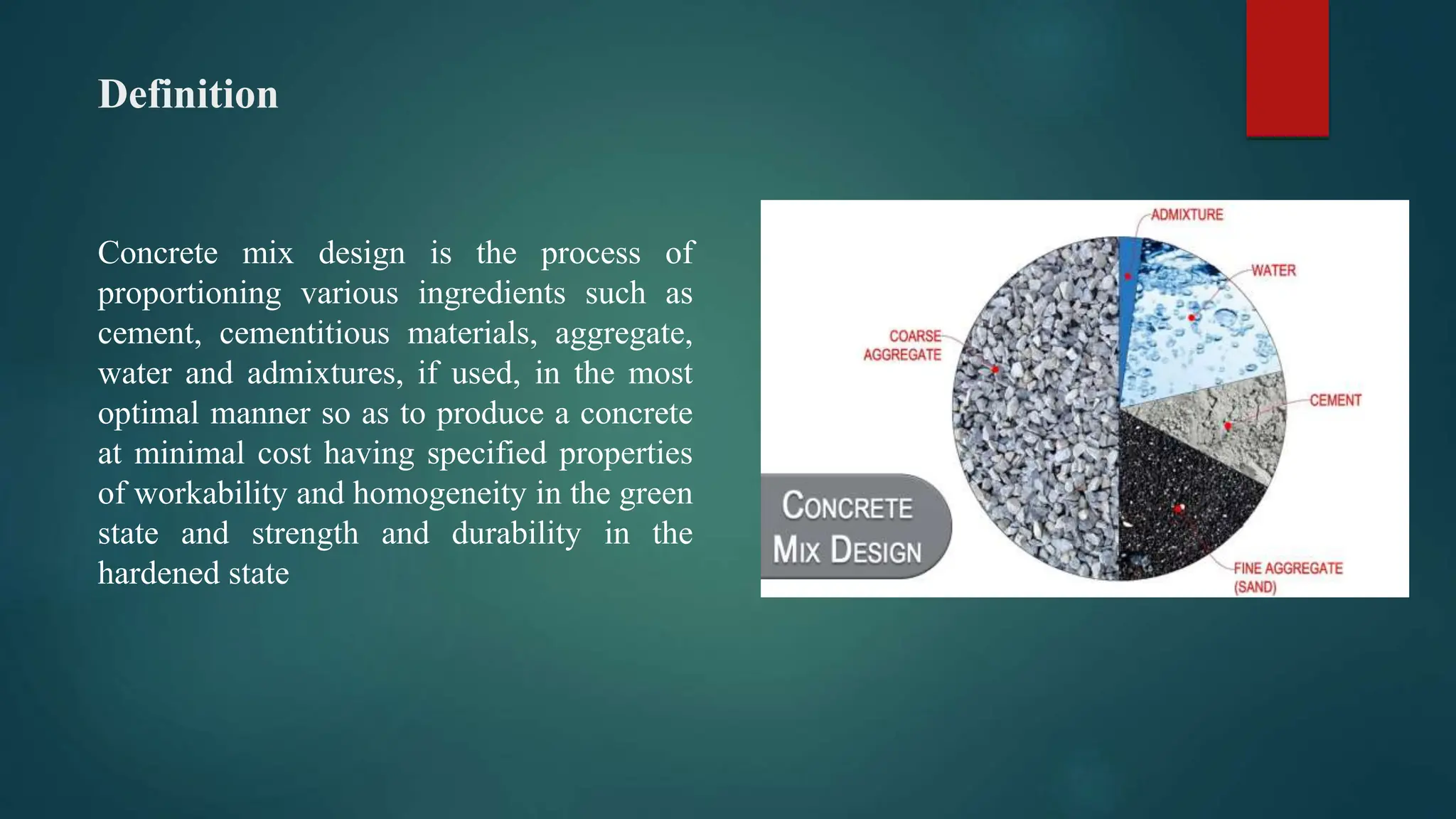

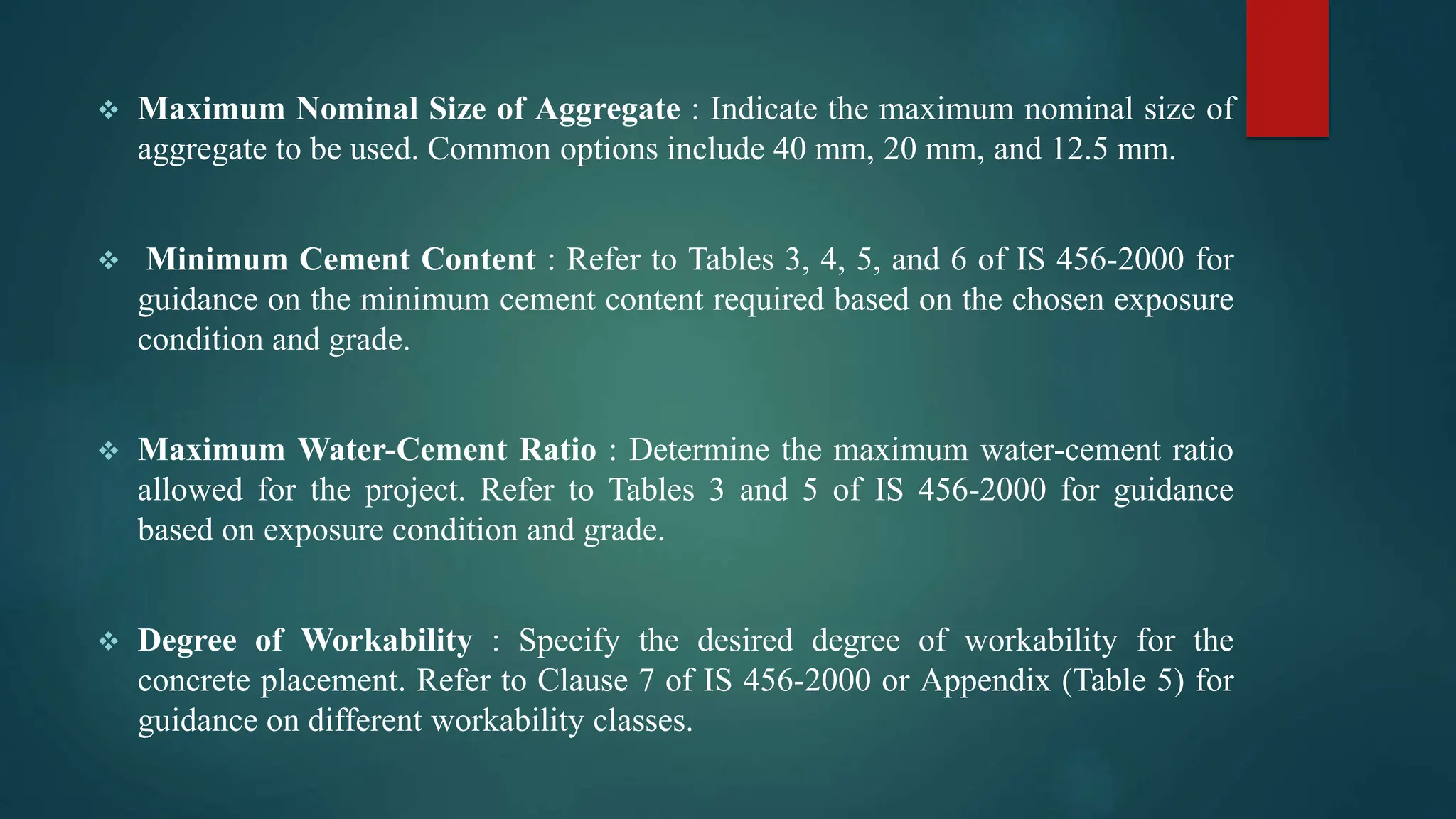

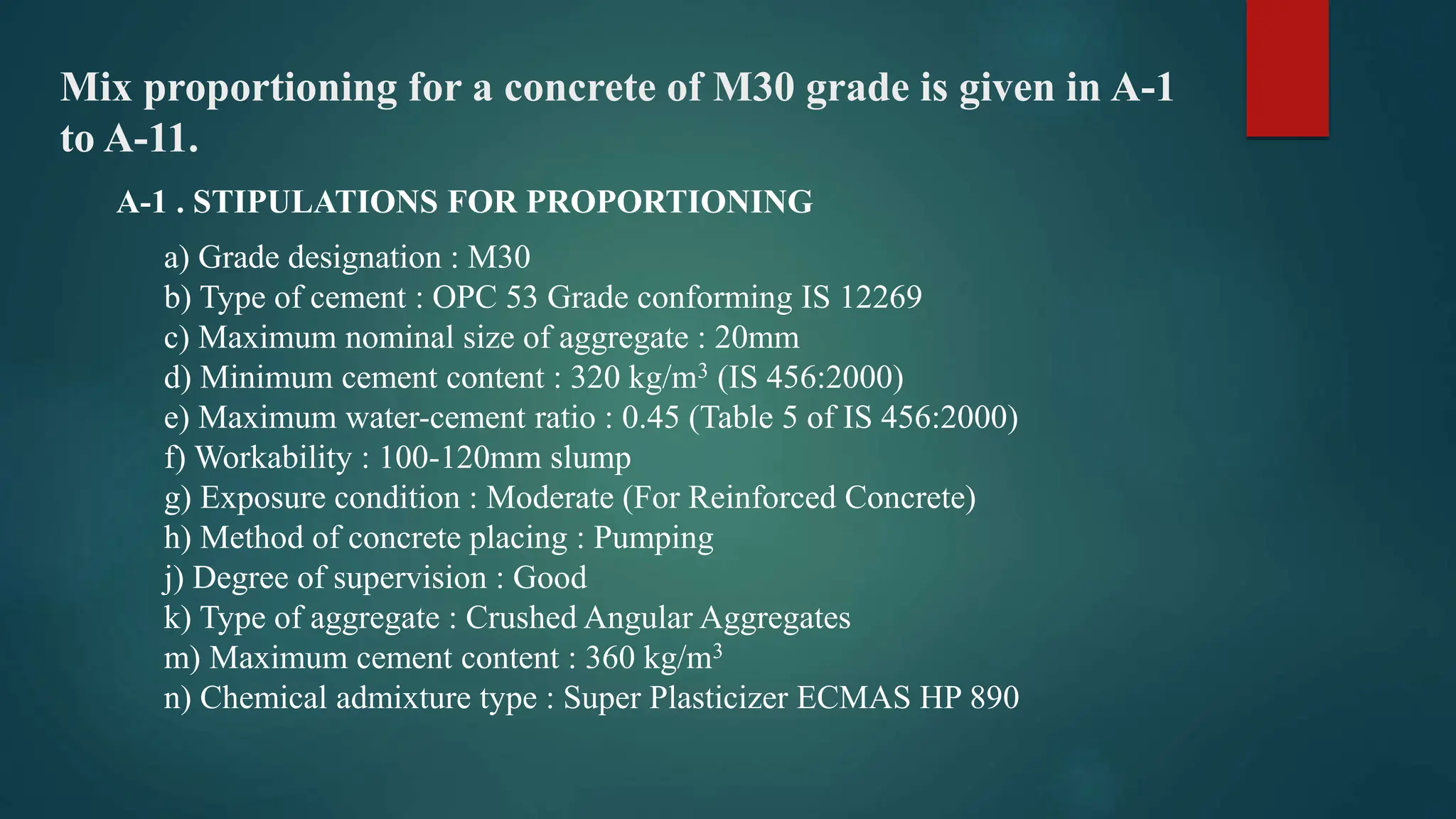

![A-8 MIX CALCULATIONS

a) Volume of concrete = 1 m3

b) Volume of cement = [Mass of cement] / {[Specific Gravity of Cement] x 1000}

= 359/{3.15 x 1000} = 0.114m3

c) Volume of water = [Mass of water] / {[Specific Gravity of water] x 1000}

= 158/{1 x 1000} = 0.158m3

d) Volume of chemical admixture = 1.75 litres/ m3 (By Trial and Error Method used

0.4% by the weight cement)

e) Volume of all in aggregate = [a-(b+c+d)] = [1-(0.114+0.158+0.004)] = 0.724m3

f) Mass of coarse aggregate= e x Volume of Coarse Aggregate x Specific Gravity of

Fine Aggregate x 1000 = 0.724x 0.576 x 2.67 x 1000 = 1113 kg/m3

g) Mass of fine aggregate= e x Volume of Fine Aggregate x Specific Gravity of Fine

Aggregate x 1000 = 0.724x 0.576x 2.60 x 1000 = 798 kg/m3

The mix calculations per unit volume of concrete shall be as follows:](https://image.slidesharecdn.com/uplod-240430120706-d74fae0a/75/Concrete-Mix-Design-by-IS-Code-Method-is-code-method-uplod-pptx-28-2048.jpg)