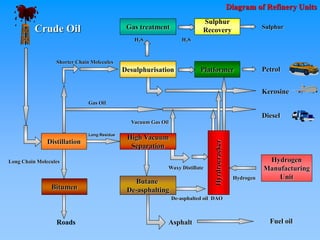

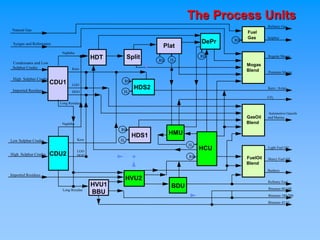

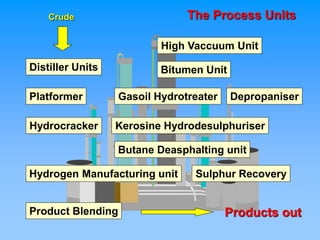

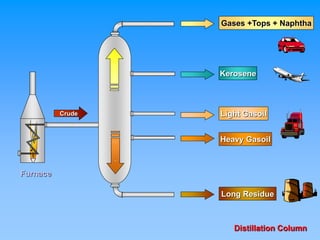

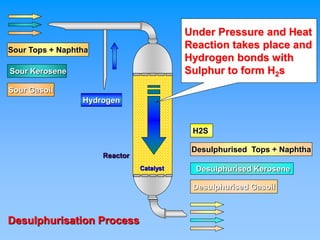

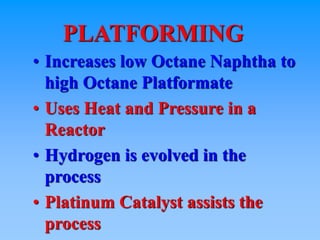

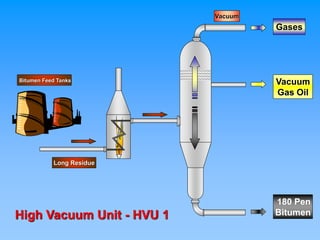

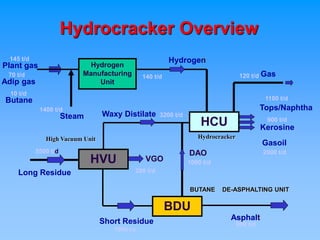

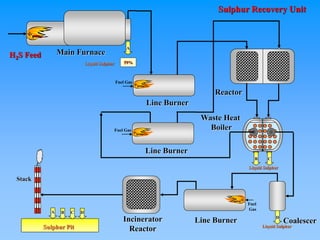

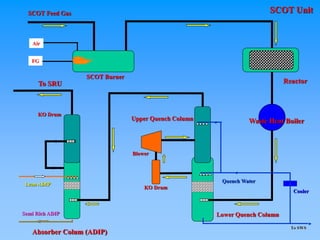

The document describes various refining processes used in an oil refinery to separate and convert crude oil into useful products. Key processes include distillation to separate crude oil into fractions like gasoline and diesel; desulfurization to remove sulfur from fuels; platforming to increase gasoline octane; hydrocracking heavier fractions into lighter products; bitumen processing; and sulfur recovery from sulfur-containing gases. The overall refining process allows crude oil to be converted into a variety of high value fuels, lubricants, and petrochemical feedstocks.