FINAL TOWN REVIEW NFC

100% SUBMITTAL

No

1/7/14

5/24/13

Revision

Plot Date:

Note: * indicates signatures on original issue of drawing or last revision of drawing

22 November 2013 - 2:41 PM

Plotted by: Ben Langston

Drawn

Job

Project

Manager Director

Cad File No:

Date

N:\US\Santa Rosa\Projects\12027 - The Town of Yountville\12027-11-001 Recycled Water Expansion Project\06-CAD\Sheets\1202711001 G-001.dw

![MITIGATION MEASURES

GENERAL NOTES

GENERAL NOTES

PROJECT MEASURE 1: BASIC AIR QUALITY MEASURES

THE CONTRACTOR SHALL IMPLEMENT THE BAY AREA AIR QUALITY MANAGEMENT DISTRICT'S BASIC CONSTRUCTION MEASURES, WHICH

CONSIST OF THE FOLLOWING:

1.

ALL EXPOSED SURFACES (E.G., PARKING AREAS, STAGING AREAS, SOIL PILES, GRADED AREAS, AND UNPAVED ACCESS ROADS)

SHALL BE WATERED UP TO TWO TIMES PER DAY AS NECESSARY TO REDUCE DUST.

ALL HAUL TRUCKS TRANSPORTING SOIL, SAND, OR OTHER LOOSE MATERIAL OFF-SITE SHALL BE COVERED.

ALL VISIBLE MUD OR DIRT TRACK-OUT ONTO ADJACENT PUBLIC ROADS SHALL BE REMOVED USING WET POWER VACUUM STREET

SWEEPERS AT LEAST ONCE PER DAY. THE USE OF DRY POWER SWEEPING IS PROHIBITED.

ALL VEHICLE SPEEDS ON UNPAVED ROADS SHALL BE LIMITED TO 15 MPH.

ALL ROADWAYS, DRIVEWAYS, AND SIDEWALKS TO BE PAVED SHALL BE COMPLETED AS SOON AS POSSIBLE.

IDLING TIMES SHALL BE MINIMIZED EITHER BY SHUTTING EQUIPMENT OFF WHEN NOT IN USE OR REDUCING THE MAXIMUM IDLING

TIME TO 5 MINUTES (AS REQUIRED BY THE CALIFORNIA AIRBORNE TOXICS CONTROL MEASURE TITLE 13, SECTION 2485 OF

CALIFORNIA CODE OF REGULATIONS [CCR]). CLEAR SIGNAGE SHALL BE PROVIDED FOR CONSTRUCTION WORKERS AT ALL ACCESS

POINTS.

ALL CONSTRUCTION EQUIPMENT SHALL BE MAINTAINED AND PROPERLY TUNED IN ACCORDANCE WITH MANUFACTURER'S

SPECIFICATIONS. ALL EQUIPMENT SHALL BE CHECKED BY A CERTIFIED MECHANIC AND DETERMINED TO BE RUNNING IN PROPER

CONDITION PRIOR TO OPERATION.

POST A PUBLICLY VISIBLE SIGN WITH THE TELEPHONE NUMBER AND PERSON TO CONTACT AT THE LEAD AGENCY REGARDING

DUST COMPLAINTS. THIS PERSON SHALL RESPOND AND TAKE CORRECTIVE ACTION WITHIN 48 HOURS. THE AIR DISTRICT'S PHONE

NUMBER SHALL ALSO BE VISIBLE TO ENSURE COMPLIANCE WITH APPLICABLE REGULATIONS.

2.

3.

4.

5.

6.

7.

8.

PROJECT MEASURE 2: TRAFFIC CONTROL PLAN

THE CONTRACTOR SHALL DEVELOP A TRAFFIC CONTROL PLAN TO MINIMIZE THE IMPACTS OF CONSTRUCTION TRAFFIC ON PROJECT

AREA ROADWAYS AND AT KEY INTERSECTIONS USED DURING CONSTRUCTION. THE TRAFFIC CONTROL PLAN SHALL INCLUDE THE

FOLLOWING PROVISIONS AND MAY INCLUDE OTHER MEASURES IF A FURTHER NEED IS IDENTIFIED.

1.

2.

LOCATION(S) OF DESIGNATED PROJECT CONSTRUCTION STAGING AREAS.

POST WARNING SIGNAGE AT POINTS WHERE CONSTRUCTION TRAFFIC WILL ENTER OR LEAVE SOLANO DR, LAND LANE, AND

SILVERADO TRAIL

USE FLAG CONTROL DURING WORK HOURS WHEN EQUIPMENT OR MATERIALS ARE DELIVERED TO THE WORK AREA.

DETOUR ROUTES TO BE USED IN ORDER TO MAINTAIN ACCESS DURING VARIOUS PHASES OF THE PROJECT'S CONSTRUCTION.

RESTRICT ALL CONSTRUCTION TRAFFIC TO NORMAL DAYTIME BUSINESS HOURS, UNLESS THE TOWN IDENTIFIES A NEED FOR

OFF-HOURS ROUTING TO AVOID IMPACTS ON PEAK-HOUR COMMUTE TRAFFIC.

CONSULT WITH THE NAPA COUNTY FIRE DEPARTMENT AND PROVIDE NOTIFICATION OF THE TIMING, LOCATION, AND DURATION OF

CONSTRUCTION IN THE VICINITY OF THE YOUNTVILLE FIRE STATION.

IN ORDER TO MINIMIZE ANY POTENTIAL OVERLAP WITH OTHER CONSTRUCTION AND ROADWAY IMPROVEMENT PROJECT(S), THE

CONTRACTOR SHALL WORK WITH THE TOWN AND NAPA COUNTY TO IDENTIFY THE ROUTES AND INTERSECTIONS THAT SHOULD BE

AVOIDED, AS WELL AS APPROPRIATE ALTERNATE TRAVEL ROUTES OR TIMES. THE PLAN SHALL ADDRESS ROUTES TO MINIMIZE

CONSTRUCTION TRAFFIC ON STATE HIGHWAY 29 DURING PEAK HOURS.

3.

4.

5.

6.

IN THE CASE OF AN UNANTICIPATED ARCHAEOLOGICAL DISCOVERY, IF IT IS DETERMINED THAT THE FIND IS UNIQUE UNDER THE

NATIONAL HISTORIC PRESERVATION ACT (NHPA) AND/OR POTENTIALLY ELIGIBLE FOR LISTING IN THE NATIONAL REGISTER, AND THE

SITE CANNOT BE AVOIDED, THE CONTRACTOR SHALL DEVELOP A RESEARCH DESIGN AND EXCAVATION PLAN, PREPARED BY AN

ARCHAEOLOGIST, OUTLINING RECOVERY OF THE RESOURCE, ANALYSIS, AND REPORTING OF THE FIND. TREATMENT AND RESOLUTION

MAY INCLUDE MODIFYING THE PROJECT TO ALLOW THE MATERIALS TO BE LEFT IN PLACE, OR UNDERTAKING DATA RECOVERY OF THE

MATERIALS IN ACCORDANCE WITH STANDARD ARCHAEOLOGICAL METHODS; PROTECTION AND PRESERVATION OF RESOURCES IS

PREFERABLE IF FEASIBLE. THE RESEARCH DESIGN AND EXCAVATION PLAN SHALL BE SUBMITTED TO RECLAMATION STAFF WHO WOULD

NOTIFY THE SHPO AND THE NATIVE AMERICAN REPRESENTATIVES. RECLAMATION AND THE SWRCB SHALL APPROVE THE PLAN PRIOR

TO CONSTRUCTION BEING RESUMED. IN THE EVENT THAT THE CONTRACTOR MUST WORK IN THE STATE RIGHT-OF-WAY (I.E. STATE

HIGHWAY 29), THE CONTRACTOR SHALL SUBMIT A STANDARD ENCROACHMENT PERMIT APPLICATION TO CALTRANS DURING THE DESIGN

OF PHASE 3 OF THE PROJECT. IF AN UNANTICIPATED ARCHAEOLOGICAL DISCOVERY DURING GROUND-DISTURBING ACTIVITIES OCCURS

WITHIN THE STATE RIGHT-OF-WAY, THE CALTRANS OFFICE OF CULTURAL RESOURCE STUDIES, DISTRICT 4, SHALL BE CONTACTED.

MITIGATION MEASURE CR-6: PROCEDURES FOR ENCOUNTERING HUMAN REMAINS

IF HUMAN REMAINS ARE DISCOVERED, POTENTIALLY DAMAGING ACTIVITIES SHALL BE HALTED AND NO FURTHER EXCAVATION OF THE

REMAINS OR NEARBY AREA CAN OCCUR UNTIL THE NAPA COUNTY CORONER HAS MADE NECESSARY FINDINGS AS TO THE ORIGIN OF

THE REMAINS, IN ACCORDANCE WITH THE HEALTH AND SAFETY CODE 7050.5. THE CONTRACTOR SHALL IMMEDIATELY NOTIFY THE

COUNTY CORONER AND A PROFESSIONAL ARCHAEOLOGIST TO DETERMINE THE NATURE OF THE REMAINS. AT THE SAME TIME, AN

ARCHAEOLOGIST SHALL BE CONTACTED TO EVALUATE THE SITUATION. AS THE PROPERTY HAS BEEN REPEATEDLY TILLED AND GRADED,

THE POSSIBILITY EXISTS THAT HUMAN REMAINS MAY BE FRAGMENTARY AND MIXED WITH SURROUNDING SOILS. IF HUMAN REMAINS ARE

ENCOUNTERED, ALL GROUND DISTURBANCE WITHIN A 50 FEET DIAMETER AREA SHALL BE HALTED UNTIL THE ARCHAEOLOGIST AND THE

CORONER HAVE REVIEWED THE REMAINS. IF THE CORONER DETERMINES THAT THE REMAINS ARE OF NATIVE AMERICAN ORIGIN, THE

TOWN SHALL NOTIFY THE NATIVE AMERICAN HERITAGE COMMISSION WITHIN 24 HOURS OF IDENTIFICATION, AS WELL AS THE

RECLAMATION REPRESENTATIVE. THE COMMISSION THEN NOTIFIES THE MOST LIKELY DESCENDANT, WHO HAS 48 HOURS TO MAKE

RECOMMENDATIONS TO THE LANDOWNER FOR THE DISPOSITION OF THE REMAINS. REMAINS SHALL BE TREATED IN ACCORDANCE WITH

PUBLIC RESOURCES CODE §5097.9.

2.

CONTRACTOR SHALL OBTAIN ALL REQUIRED PERMITS AND PAY ALL FEES PRIOR TO COMMENCEMENT OF

ANY WORK EXCEPT THOSE SPECIFICALLY NOTED IN SPECIFICATIONS AS PROVIDED BY TOWN OF

YOUNTVILLE

3.

CONTRACTOR SHALL OBTAIN AN ENCROACHMENT PERMIT FROM NAPA COUNTY, CA BEFORE START OF

WORK. CONTRACTOR SHALL COMPLY WITH ALL REQUIREMENTS OF THE PERMIT

WORK HOURS ARE LIMITED TO MONDAY THROUGH FRIDAY 8 A.M. TO 5 P.M. AT THE PROJECT SITE AND 7:30

A.M. TO 4 P.M. AT THE TREATMENT PLANT. TIME AT THE TREATMENT PLANT HAS SOME FLEXIBILITY;

HOWEVER DIFFERING HOURS NEED TO BE COORDINATED WITH DON MOORE, UTILITY OPERATIONS

SUPERVISOR. INSPECTION WILL BE AVAILABLE MONDAY THROUGH FRIDAY FROM 8 A.M. TO 4 P.M. ANY

WEEKEND WORK IS SUBJECT TO TOWN APPROVAL.

5.

PRE-CONSTRUCTION MEETING IS REQUIRED PRIOR TO BEGINNING OF WORK. CONTACT THE ENGINEER TO

SCHEDULE SUCH MEETING.

6.

IF PALEONTOLOGICAL RESOURCES (E.G., VERTEBRATE BONES, TEETH, OR ABUNDANT AND WELL-PRESERVED INVERTEBRATES OR

PLANTS) ARE ENCOUNTERED DURING CONSTRUCTION, THE TOWN SHALL HALT GROUND-DISTURBING WORK IN THE VICINITY OF THE

FIND. WORK NEAR THE FIND SHALL NOT BE RESUMED UNTIL A QUALIFIED PALEONTOLOGIST HAS EVALUATED THE MATERIALS AND

OFFER RECOMMENDATIONS FOR FURTHER ACTION, INCLUDING SALVAGE OF ANY SIGNIFICANT PALEONTOLOGICAL RESOURCES.

ANY DISCREPANCY DISCOVERED BY CONTRACTOR IN THESE PLANS OR ANY FIELD CONDITIONS

DISCOVERED BY CONTRACTOR THAT MAY DELAY OR OBSTRUCT THE PROPER COMPLETION OF THE WORK

PER THESE PLANS SHALL BE BROUGHT TO THE ATTENTION OF THE ENGINEER AND THE OWNER

IMMEDIATELY UPON DISCOVERY. SAID NOTIFICATION SHALL BE IN WRITING.

4.

MITIGATION MEASURE CR-5: PROTECTION AND PRESERVATION OF PALEONTOLOGICAL MATERIALS

1.

WITHIN 48 HOURS OF PAVING, ALL WATER VALVE BOXES WILL BE BROUGHT TO GRADE AND INSPECTION

REQUESTED.

GENERAL UNDERGROUND NOTES

1.

NO GUARANTEE IS INTENDED THAT UNDERGROUND OBSTRUCTIONS NOT SHOWN ON THESE PLANS MAY

BE ENCOUNTERED. THOSE SHOWN ARE BASED ON THE BEST INFORMATION AVAILABLE AND THE

CONTRACTOR IS CAUTIONED THAT THE OWNER, THE ENGINEERS, AND THE TOWN OF YOUNTVILLE

ASSUME NO RESPONSIBILITY FOR ANY OBSTRUCTIONS EITHER SHOWN OR NOT SHOWN ON THESE PLANS.

THE CONTRACTOR SHALL COOPERATE WITH ALL UTILITY COMPANIES WORKING WITHIN THE LIMITS OF

THIS PROJECT.

2.

CONTRACTOR SHALL NOT BEGIN EXCAVATION UNTIL ALL EXISTING UTILITIES HAVE BEEN MARKED IN THE

FIELD BY THE APPLICABLE ENTITY RESPONSIBLE FOR THAT PARTICULAR UTILITY. THE CONTRACTOR

SHALL NOTIFY EACH APPLICABLE ENTITY AT LEAST 24 HOURS BEFORE STARTING WORK.

3.

UNDERGROUND SERVICE ALERT: CALL TOLL FREE (800) 642-2444 AT LEAST 48 HOURS PRIOR TO

EXCAVATION.

4.

CONTRACTOR SHALL UNCOVER EXISTING BURIED UTILITIES IN THE PRESENCE OF UTILITY OWNER TO

VERIFY LOCATIONS AND ELEVATIONS OF UTILITIES. BURIED UTILITIES INCLUDE, BUT ARE NOT LIMITED TO,

WATER MAINS AND SERVICES, SEWER MAINS AND LATERALS, STORM DRAINS, GAS MAINS AND LATERALS,

ELECTRICAL DISTRIBUTION LINES, TELEPHONE AND CABLE TV LINES. ALL UTILITIES CONFLICTING WITH

THE PROPOSED CONSTRUCTION SHALL BE RELOCATED OR RESOLVED PRIOR TO THE START OF

CONSTRUCTION, OR CONFLICTING FACILITIES

5.

ALL UNDERGROUND IMPROVEMENTS SHALL BE INSTALLED AND APPROVED PRIOR TO PAVING.

6.

ALL MATERIAL, WORKMANSHIP AND CONSTRUCTION DETAILS SHALL CONFORM TO THE TOWN OF

YOUNTVILLE CONSTRUCTION STANDARD SPECIFICATIONS, INCLUDING ALL ADDENDA, STANDARD PLAN

AND SPECIAL PROVISION REVISIONS.

IF CONSTRUCTION DEWATERING IS REQUIRED, THE TOWN SHALL EVALUATE REASONABLE OPTIONS FOR DEWATERING MANAGEMENT.

THE FOLLOWING MANAGEMENT OPTIONS SHALL BE CONSIDERED:

7.

ITEMS SPECIFIED ON THE STANDARD PLANS ARE APPROVED FOR USE BY THE TOWN OF YOUNTVILLE. ALL

SUBSTITUTES OR ALTERATIONS SHALL BE SUBMITTED TO THE TOWN OF YOUNTVILLE FOR REVIEW AND

APPROVAL.

1.

2.

3.

RECYCLED WATER SYSTEM

MITIGATION MEASURE HYD- 1: STORM WATER POLLUTION PREVENTION PLAN

THE CONTRACTOR SHALL IMPLEMENT THE FOLLOWING MEASURES TO AVOID IMPACTS TO CALIFORNIA RED-LEGGED FROGS (CRLF)

DURING CONSTRUCTION WITHIN 50 FEET OF THE AGRICULTURAL IRRIGATION PONDS:

THE CONTRACTOR SHALL OBTAIN COVERAGE UNDER SWRCB (STATE WATER RESOURCES CONTROL BOARD) ORDER NO. 2009-0009-DWQ,

WASTE DISCHARGE REQUIREMENTS FOR DISCHARGES OF STORM WATER RUNOFF ASSOCIATED WITH CONSTRUCTION AND LAND

DISTURBANCE ACTIVITIES.

THE CONTRACTOR SHALL SUBMIT PERMIT REGISTRATION DOCUMENTS (NOTICE OF INTENT, RISK,

ASSESSMENT, SITE MAPS, SWPPP, ANNUAL FEE, AND CERTIFICATIONS) TO THE STATE WATER RESOURCES CONTROL BOARD. THE

SWPPP SHALL ADDRESS POLLUTANT SOURCES, NON-STORM WATER DISCHARGES RESULTING FROM CONSTRUCTION DEWATERING,

BEST MANAGEMENT PRACTICES, AND OTHER REQUIREMENTS SPECIFIED IN THE ORDER. THE BMPS SHALL INCLUDE ANY MEASURES

INCLUDED IN THE EROSION AND SEDIMENT CONTROL PLANS DEVELOPED FOR THE PROJECT TO MINIMIZE DISTURBANCE AFTER

GRADING OR CONSTRUCTION. THE SWPPP SHALL ALSO INCLUDE DUST CONTROL PRACTICES TO PREVENT WIND EROSION, SEDIMENT

TRACKING AND DUST GENERATION BY CONSTRUCTION EQUIPMENT. THE CONTRACTOR SHALL ENSURE THAT A QUALIFIED SWPPP

PRACTITIONER OVERSEES IMPLEMENTATION OF THE SWPPP, INCLUDING VISUAL INSPECTIONS, SAMPLING AND ANALYSIS, AND

ENSURING OVERALL COMPLIANCE.

1.

MITIGATION MEASURE HYD- 2: CONSTRUCTION DEWATERING

7.

MITIGATION MEASURE BIO-1: AVOID IMPACTS TO CALIFORNIA RED-LEGGED FROG

GROUND DISTURBING CONSTRUCTION ACTIVITIES SHALL BE LIMITED TO THE DRY SEASON PERIOD FROM APRIL 1 THROUGH

NOVEMBER 1 TO AVOID POTENTIAL RED-LEGGED FROG DISPERSAL EVENTS.

A QUALIFIED BIOLOGIST, HIRED BY THE CONTRACTOR BUT APPROVED BY THE TOWN, SHALL CONDUCT A PRE-CONSTRUCTION

SURVEY IMMEDIATELY PRECEDING ANY CONSTRUCTION ACTIVITY WITHIN 50 FEET OF THE IRRIGATION PONDS. THE BIOLOGIST

SHALL REMAIN ON-SITE DURING GROUND DISTURBING CONSTRUCTION WITHIN 50 FEET OF A POND.

IF A CRLF IS ENCOUNTERED DURING CONSTRUCTION, ALL CONSTRUCTION ACTIVITIES IN THE IMMEDIATE AREA SHALL CEASE

UNTIL THE ANIMAL MOVES AWAY OF ITS OWN VOLITION. CONSTRUCTION CANNOT BEGIN UNTIL THE CRLF HAS LEFT THE

CONSTRUCTION AREA. IF CRLF DO NOT LEAVE THE SITE TO ALLOW FOR CONSTRUCTION, THE TOWN SHALL CONTACT USFWS FOR

DIRECTION ON HOW TO PROCEED.

PRIOR TO THE START OF CONSTRUCTION, A USFWS-APPROVED BIOLOGIST SHALL TRAIN ALL CONSTRUCTION PERSONNEL

REGARDING HABITAT SENSITIVITY, IDENTIFICATION OF SPECIAL STATUS SPECIES, AND REQUIRED PRACTICES BEFORE THE START

OF CONSTRUCTION.

BECAUSE DUSK AND DAWN ARE OFTEN THE TIMES WHEN CRLF ARE MOST ACTIVELY FORAGING AND DISPERSING, ALL

CONSTRUCTION ACTIVITIES SHALL CEASE ONE-HALF HOUR BEFORE SUNSET AND SHALL NOT BEGIN PRIOR TO ONE-HALF HOUR

BEFORE SUNRISE. ALL VEHICLE PARKING SHALL BE RESTRICTED TO PREVIOUSLY DETERMINED STAGING AREAS OR EXISTING

ROADS.

THE FUELING AND MAINTENANCE OF VEHICLES AND OTHER EQUIPMENT SHALL OCCUR AT LEAST 20 METERS (65 FEET) FROM ANY

RIPARIAN HABITAT OR WATER BODY.

2.

3.

4.

5.

6.

IF CONSTRUCTION IS SCHEDULED TO START BETWEEN JANUARY 31 AND OCTOBER 1, A QUALIFIED BIOLOGIST, HIRED BY THE

CONTRACTOR BUT APPROVED BY THE TOWN, SHALL CONDUCT PRECONSTRUCTION NESTING SURVEYS WITHIN 48 HOURS OF

CONSTRUCTION FOR NESTING PASSERINES (SMALL SONGBIRDS) AND RAPTORS. TREES WITHIN A 200-FOOT RADIUS SHALL BE INCLUDED

IN THE SURVEYS. IF ACTIVE NESTS ARE LOCATED IN THE WORK AREA, THE BIOLOGIST, IN CONSULTATION WITH CDFG, (CALIFORNIA

DEPARTMENT OF FISH AND GAME), SHALL ESTABLISH AN APPROPRIATELY SIZED BUFFER AROUND THE NEST IN WHICH NO WORK WILL

BE ALLOWED UNTIL THE YOUNG HAVE SUCCESSFULLY FLEDGED. A MINIMUM OF A 50-FOOT BUFFER ZONE SHALL BE PLACED AROUND

PASSERINE NESTS AND 250-FOOT BUFFERS SHALL BE PLACED AROUND RAPTOR NESTS. IF A QUALIFIED BIOLOGIST DETERMINES THAT

LESS OF A BUFFER ZONE IS ACCEPTABLE, THE SIZE OF THE BUFFER ZONE MAY BE REDUCED UPON APPROVAL BY CDFG.

BIO-3:

AVOID

OR RESTORE

JURISDICTIONAL

WETLANDS

AND WATERS

TEMPORARILY

AFFECTED

BY

THE CONTRACTOR SHALL IMPLEMENT AVOIDANCE AND MINIMIZATION MEASURES, INCLUDING BEST MANAGEMENT PRACTICES (BMPS),

TO PROTECT JURISDICTIONAL WETLANDS AND WATERS DURING CONSTRUCTION. MATERIALS AND FLUIDS GENERATED BY

CONSTRUCTION ACTIVITIES SHALL BE PLACED AT LEAST 25 FEET AWAY FROM WETLAND AREAS OR DRAINAGES UNTIL THEY CAN BE

DISPOSED OF AT A PERMITTED SITE. ALL WETLANDS AND WATERS AREAS LOCATED ADJACENT TO THE CONSTRUCTION ZONE THAT

COULD BE AFFECTED BY CONSTRUCTION ACTIVITIES SHALL BE TEMPORARILY FENCED OFF AND DESIGNATED AS ENVIRONMENTALLY

SENSITIVE AREAS TO PREVENT ACCIDENTAL INTRUSION BY WORKERS AND EQUIPMENT.

IF DISCHARGING TO THE SANITARY SEWER, THE TOWN SHALL ISSUE A ONE-TIME DISCHARGE PERMIT OR OTHER TYPE OF APPROVAL

REQUIRING, AS NECESSARY, MEASURES FOR CHARACTERIZING THE DISCHARGE AND ENSURING FILTERING METHODS AND MONITORING

TO VERIFY THAT THE DISCHARGE IS COMPLIANT WITH THE TOWN'S LOCAL WASTEWATER DISCHARGE REQUIREMENTS.

IF DISCHARGING TO A LOCAL SURFACE WATER OR STORM DRAIN, THE DISCHARGE SHALL BE MANAGED AS A NON-STORM WATER

DISCHARGE AND CONTROL MEASURES SHALL BE INCLUDED IN THE SWPPP PREPARED UNDER ORDER NO. 2009-0009-DWQ. THE

CONTRACTOR SHALL CHARACTERIZE THE GROUNDWATER PRIOR TO DISCHARGE AND IMPLEMENT CONTROL MEASURES, SUCH AS

SETTLING AND/OR FILTRATION TO ENSURE THAT EXCESSIVE SEDIMENT IS NOT DISCHARGED, AND MANAGE DISCHARGE RATES TO

PREVENT EROSION DOWNSTREAM.

1.

2.

3.

INSTALL PIPELINES WHEN WETLANDS AND STREAMS ARE DRY.

RESTORE ORIGINAL CONTOURS AND DRAINAGE PATTERNS, BOTH INTO AND OUT OF THE WETLAND.

SPREAD A COVER OF STRAW, RICE STRAW IF AVAILABLE, OVER DISTURBED SOILS AND WORK INTO SOIL. THIS PRACTICE SHALL

NOT BE IMPLEMENTED IN WETLAND SOILS.

APPLY AN ORGANICALLY BASED TACKIFIER ON DISTURBED AREAS TO REDUCE AIR AND WATER EROSION OF SOILS.

PLANTS SHALL BE INSTALLED, MAINTAINED AND REPLACED SUCH THAT 70 PERCENT OF THE DESIGN PLANT DENSITY IS PRESENT

ON THE FIVE-YEAR ANNIVERSARY OF PLANT INSTALLATION.

4.

5.

THERE SHALL BE A FIVE HOUR MAXIMUM SHUTDOWN TIME OF EXISTING MAINS WHILE MAKING

CONNECTION. TWENTY-FOUR HOUR NOTICE OF SHUTDOWN TO BE GIVEN TO TOWN AND ALL WATER

CUSTOMERS BY CONTRACTOR. EXISTING VALVES ARE TO BE OPERATED BY TOWN PERSONNEL ONLY. NO

WATER MAIN CONNECTIONS ARE PERMITTED ON FRIDAY OR ON ANY DAY PRECEDING A HOLIDAY.

2.

START EXCAVATION BY EXPOSING CONNECTION POINT TO EXISTING MAIN TO DETERMINE ITS LINE AND

GRADE. START NEW MAIN 8-10 FEET FROM AND ON SAME GRADE (AND LINE IF APPLICABLE) AS EXISTING

MAIN.

3.

ALL TRENCHING, BACKFILL AND RESURFACING REQUIRED FOR INSTALLATION OF RECYCLED WATER

SYSTEM FACILITIES SHALL BE PER TOWN OF YOUNTVILLE STANDARD DRAWINGS.

ONLY TOWN OF YOUNTVILLE PERSONNEL SHALL OPERATE VALVES ON EXISTING WATER MAINS OR WATER

SERVICES.

5.

ALL METER BOXES, VAULTS AND PITS SHALL BE BEDDED ON A 3" MINIMUM THICK, 3/4" DRAIN ROCK, CL ll

AB, OR OTHER CLEAN MATERIAL WITH SAND EQUIVALENT OF 20 MINIMUM, UNCONTAMINATED BY NATIVE

SOIL, AGAINST COMPACTED OR UNDISTURBED BASE. THE GRAVEL BED SHALL EXTEND TO A MINIMUM OF

4" BEYOND ALL SIDES OF THE METER BOX. BOX SHALL BE SET FLUSH WITH TOP OF CURB, SIDEWALK OR

GROUND, WHICHEVER IS APPLICABLE.

6.

BEFORE COMBUSTIBLE MATERIALS MAY BE STORED OR CONSTRUCTED ON SITE, THE FIRE DEPARTMENT

MUST APPROVE FIRE FLOW AND ACCESS.

7.

AFTER A STREET HAS BEEN PAVED, ALL WATER VALVE BOXES WILL BE MARKED IN WHITE PAINT BEFORE

THE CLOSE OF THAT WORK DAY.

MITIGATION MEASURE NOI-1: NOISE REDUCTION MEASURES

DURING PROJECT CONSTRUCTION, THE CONTRACTOR(S) SHALL IMPLEMENT THE FOLLOWING MEASURES SUCH THAT NOISE FROM

CONSTRUCTION DOES NOT EXCEED 70 DBA AT NOISE-SENSITIVE USES DURING DAYTIME HOURS.

1.

2.

3.

4.

5.

THE FOLLOWING MEASURES SHALL BE IMPLEMENTED WHERE CONSTRUCTION IMPACTS TO JURISDICTIONAL WATERS AND WETLANDS

CANNOT FEASIBLY BE AVOIDED. A WETLAND AND WATERS RESTORATION PLAN SHALL BE PREPARED PRIOR TO CONSTRUCTION. THE

RESTORATION SHALL INCLUDE, BUT NOT BE LIMITED TO, THE FOLLOWING MEASURES:

1.

4.

MITIGATION MEASURE BIO-2: CONDUCT PRECONSTRUCTION NESTING SURVEYS FOR NESTING PASSERINES AND RAPTORS

MITIGATION MEASURE

CONSTRUCTION

REUSE THE WATER ON-SITE FOR DUST CONTROL, COMPACTION, OR IRRIGATION.

RETAIN THE WATER ON-SITE IN A GRASSY OR POROUS AREA TO ALLOW INFILTRATION/EVAPORATION.

DISCHARGE (BY PERMIT) TO A SANITARY SEWER OR SURFACE WATER (THIS OPTION MAY REQUIRE A TEMPORARY METHOD TO

FILTER SEDIMENT-LADEN WATER PRIOR TO DISCHARGE).

6.

CONSTRUCTION WORK HOURS ARE LIMITED TO MONDAY THROUGH FRIDAY 8 A.M. TO 5 P.M. AT THE PROJECT SITE AND 7:30 A.M. TO

4 P.M. AT THE TREATMENT PLANT.

USE QUIETEST AVAILABLE EQUIPMENT AND ELECTRICALLY-POWERED EQUIPMENT, RATHER THAN INTERNAL COMBUSTION

ENGINES WHERE FEASIBLE.

EQUIPMENT AND ON-SITE TRUCKS USED FOR PROJECT CONSTRUCTION SHALL UTILIZE THE BEST AVAILABLE NOISE CONTROL

TECHNIQUES (E.G., IMPROVED MUFFLERS, EQUIPMENT REDESIGN, USE OF INTAKE SILENCERS, DUCTS, ENGINE ENCLOSURES, AND

ACOUSTICALLY ATTENUATING SHIELDS OR SHROUDS, WHEREVER FEASIBLE). ALL CONSTRUCTION EQUIPMENT SHALL BE

INSPECTED AT PERIODIC INTERVALS TO ENSURE PROPER MAINTENANCE AND RESULTING LOWER NOISE LEVELS.

IMPACT TOOLS (E.G., JACK HAMMERS, PAVEMENT BREAKERS) USED FOR PROJECT CONSTRUCTION SHALL BE HYDRAULICALLY OR

ELECTRICALLY POWERED WHEREVER POSSIBLE TO AVOID NOISE ASSOCIATED WITH COMPRESSED-AIR EXHAUST FROM

PNEUMATICALLY POWERED TOOLS. AN EXHAUST MUFFLER ON THE COMPRESSED-AIR EXHAUST SHALL BE USED; THIS MUFFLER

CAN LOWER NOISE LEVELS FROM THE EXHAUST BY UP TO ABOUT 10 DBA. EXTERNAL JACKETS ON THE TOOLS THEMSELVES SHALL

BE USED WHERE FEASIBLE, WHICH COULD ACHIEVE A REDUCTION OF 5 DBA.

A PRECONSTRUCTION MEETING SHALL BE HELD BETWEEN THE JOB INSPECTORS AND THE CONTRACTOR/ON-SITE PROJECT

MANAGER TO CONFIRM THAT NOISE MITIGATION AND PRACTICES ARE COMPLETED PRIOR TO COMMENCEMENT OF CONSTRUCTION

(INCLUDING CONSTRUCTION HOURS, NEIGHBORHOOD NOTIFICATION, ETC.).

AN ON-SITE COMPLAINT AND ENFORCEMENT MANAGER SHALL BE POSTED TO RESPOND TO AND TRACK ANY NOISE COMPLAINTS.

THE MANAGER SHALL BE RESPONSIBLE FOR RESPONDING TO ANY COMPLAINTS REGARDING CONSTRUCTION NOISE AND FOR

COORDINATING WITH THE ADJACENT LAND USES. THE MANAGER SHALL DETERMINE THE CAUSE OF ANY COMPLAINTS AND

COORDINATE WITH THE CONSTRUCTION TEAM TO IMPLEMENT EFFECTIVE MEASURES (CONSIDERED TECHNICALLY AND

ECONOMICALLY FEASIBLE) WARRANTED TO CORRECT THE PROBLEM. THE TELEPHONE NUMBER OF THE ON-SITE COMPLAINT AND

ENFORCEMENT MANAGER SHALL BE POSTED AT THE CONSTRUCTION SITE AND PROVIDED TO NEIGHBORS IN A NOTIFICATION

LETTER. THE MANAGER SHALL BE TRAINED TO USE A SOUND LEVEL METER AND SHOULD BE AVAILABLE DURING ALL

CONSTRUCTION HOURS TO RESPOND TO COMPLAINTS.

MITIGATION MEASURE CR-4: TREATMENT OF ARCHAEOLOGICAL RESOURCES DISCOVERED DURING CONSTRUCTION

IF ARCHAEOLOGICAL MATERIALS ARE ENCOUNTERED DURING CONSTRUCTION ACTIVITIES, THE PIECE OF EQUIPMENT THAT

ENCOUNTERS THE MATERIALS MUST BE STOPPED, AND THE FIND INSPECTED BY A QUALIFIED ARCHAEOLOGIST, HIRED BY THE

CONTRACTOR BUT APPROVED BY THE TOWN, TO EVALUATE THE MATERIALS AND RECOMMEND APPROPRIATE TREATMENT.

PREHISTORIC ARCHAEOLOGICAL MATERIALS MIGHT INCLUDE OBSIDIAN AND CHERT FLAKED-STONE TOOLS (E.G., PROJECTILE POINTS,

KNIVES, SCRAPERS) OR TOOLMAKING DEBRIS; CULTURALLY DARKENED SOIL (“MIDDEN”) CONTAINING HEAT-AFFECTED ROCKS,

ARTIFACTS, OR SHELLFISH REMAINS; AND STONE MILLING EQUIPMENT (E.G., MORTARS, PESTLES, HANDSTONES, OR MILLING SLABS);

AND BATTERED STONE TOOLS, SUCH AS HAMMERSTONES AND PITTED STONES. HISTORIC PERIOD MATERIALS MIGHT INCLUDE STONE,

CONCRETE, OR ADOBE FOOTINGS AND WALLS; FILLED WELLS OR PRIVIES; AND DEPOSITS OF METAL, GLASS, AND/OR CERAMIC REFUSE.

Reuse of Documents

Drawn

This document and the ideas and designs incorporated

herein, as an instrument of professional service, is the

property of GHD Inc. and shall not be reused in whole or

in part for any other project without GHD Inc.'s written

authorization. © GHD Inc. 2012

FINAL TOWN REVIEW NFC

100% SUBMITTAL

No

1/7/14

5/24/13

Revision

Plot Date:

Note: * indicates signatures on original issue of drawing or last revision of drawing

25 November 2013 - 1:32 PM

Plotted by: Ben Langston

Drawn

Job

Project

Manager Director

Cad File No:

Date

N:USSanta RosaProjects12027 - The Town of Yountville12027-11-001 Recycled Water Expansion Project06-CADSheets1202711001 G-004.dwg

BL

Designer MJ

Client

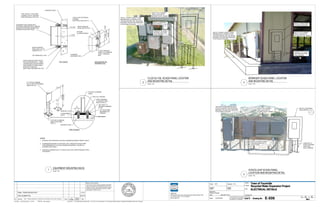

Project

Drafting SD

Check

GHD Inc.

2235 Mercury Way Suite 150 Santa Rosa California 95407 USA

T 1 707 523 1010 F 1 707 527 8679

W www.ghd.com

Design

Check

WZ

Approved

(Project Director)

JANUARY 2014

Date

Scale

NONE

This Drawing shall not be used

for Construction unless Signed

and Sealed For Construction

Title

Contract No.

Original Size

G-004

Sht

4

of

50](https://image.slidesharecdn.com/recycledwaterprojectdraftplansandspecifications-131226163747-phpapp02/85/Recycled-water-project-draft-plans-and-specifications-4-320.jpg)

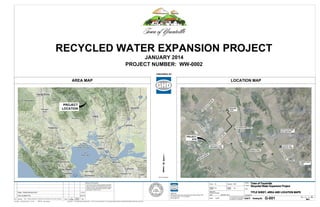

![PANELBOARD SCHEDULE NOTES

NORTH

VALVE VAULT

GENERAL CIRCUIT/CONDUIT TAG ID

TAG

CONDUIT SIZE

Px

3/4" (x=2 THRU 12)

x-#12, 1-#12G

Cx

3/4" (x=2 THRU 18)

1" (x=19 THRU 30)

2" (x=31 THRU 100)

VALVE

ACTUATOR

VA-1

CONDUCTORS

M

2.

MFR'S CABLE

x-#14, 1-#12G

C10

LE

TSP-2

3/4" (X=1,2)

1" (x=3,4)

2" (x=5 THRU 16)

TSP-x

x-#16 TWISTED SHIELDED PAIR

3/4" (x=1 THRU 4)

1" (x=5 THRU 8)

CAT6-x

3.

P3

2

LE

REFER TO DUCT BANK SECTION SCHEDULE

FOR REQUIREMENTS

DB-XX [XX] w/CIRCUIT

1.

WET WELL

P2

TSP-2

TSP-1

x-CATEGORY 6 NETWORK CABLE

ULS

C10

3/4" C, 2#12, 1#12 G

THREE PHASE CIRCUITS : PROVIDE 3/4"C w/3-#12, 1-#12 GRD FOR 20A

CIRCUITS SERVING EQUIPMENT WITHIN 60' OF PANELBOARD, UNLESS

OTHERWISE NOTED. INCREASE CONDUIT AND WIRE SIZES IN

ACCORDANCE WITH THE NEC FOR LONGER CIRCUITS OR CIRCUITS MORE

THAN 20A.

SINGLE PHASE CIRCUITS : PROVIDE 3/4"C w/2-#12, 1-#12 GRD FOR 20A

CIRCUITS SERVING EQUIPMENT WITHIN 60' OF PANELBOARD, UNLESS

OTHER WISE NOTED. INCREASE CONDUIT AND WIRE SIZE IN

ACCORDANCE WITH THE NEC FOR LONGER CIRCUITS OR CIRCUITS MORE

THAN 20A.

RECEPTACLE CIRCUITS SHALL BE POWERED THROUGH A GFCI CIRCUIT

BREAKER, EXCEPT AS FOLLOWS:

· WHEN THE DISTANCE TO THE FIRST RECEPTACLE IS OVER 50' IN

LENGTH, USE A STANDARD CIRCUIT BREAKER AND PROVIDE A FEED

THROUGH GFCI TYPE RECEPTACLE.

· ALL RECEPTACLES MOUNTED IN LIGHT POLES OR ON HANDRAILS

SHALL BE GFCI TYPE.

· PROVIDE GFCI RECEPTACLES AT ALL LOCATIONS WHERE

RECEPTACLES ARE MORE THAN 50' APART.

· PROVIDE GFCI RECEPTACLES FOR ALL SINGLE PHASE CORD

CONNECTED, SUBMERSIBLE PUMP, MIXERS, ETC.

4.

5.

6.

7.

8.

9.

10.

· REFER TO SPECIFICATIONS FOR ADDITIONAL INFORMATION.

CONDUIT SIZES SHOWN ARE MINIMUM ONLY AND NOT FOR USE IN

DUCTBANKS. REFER TO DUCTBANK AND CIRCUIT SCHEDULE FOR

CONDUIT SIZE AND FOR CONDUITS WHICH STUB-UP INTO PANELBOARDS.

LIGHTING CIRCUITS : PROVIDE ADDITIONAL CONDUCTORS AS REQUIRED

TO CONNECT SWITCHED LEGS FOR FIXTURES OR UNSWITCHED LEGS

FOR EMERGENCY LIGHTING UNITS AND EXIT LIGHTS. EMERGENCY

LIGHTING UNITS AND EXIT LIGHTS SHALL BE CONNECTED UPSTREAM OF

SWITCHED DEVICES.

LOCKOUT PROVISIONS : PROVIDE HANDLE LOCK-OFF/PADLOCK

ATTACHMENT FEATURE.

PROVIDE GROUND FAULT EQUIPMENT PROTECTOR RATED BREAKER

(GFEP).

PROVIDE HEATING, AIR-CONDITIONING, REFRIGERATION RATED BREAKER

(HACR).

UNIT HEATER CONNECTIONS : CONTRACTOR SHALL COORDINATE

CONNECTIONS WITH FINAL UNIT HEATER SELECTION. PROVIDE

NECESSARY 3 ɸ OR 1 ɸ BRANCH CIRCUITS AS REQUIRED PER EACH UNIT.

UNUSED BRANCH CIRCUITS SHALL BE LABELED AS SPARE.

CKTS MAY ALSO BE ROUTED THROUGH DUCT BANKS.

UTILITY RTU

OIT

UTILITY ROOM

EXISTING CONDUIT W/ MODBUS

EXISTING

PANELBOARD "D"

CONTROL ROOM

EX

MASTER RTU

3/4" C, 2#10, 1#12G

EXISTING

WP

CR

FIT

B-19

TSP-1

CS

C2

C10

EXISTING

SWITCHBOARD "B"

P2

TSP-2

1

HP

B-20

AE

2

AIT

AE

TO BE PROVIDED

AND INSTALLED

BY OTHERS

CL

CHLORINE SAMPLE PUMP

ANALOG & DISCRETE

FLEXIBLE CABLES (TYP)

CABLE

CONNECTOR (TYP)

EXISTING MILTRONICS

FLOW METER

HACH CL-17

EXISTING

PANELBOARD B

TSP-2

C10

TSP-1

CONTROLS

M

P2

ACCESS

CONTROL

UNIT

OIT

BISULFITE METERING

PUMP

#2

P2

3/4" C, 3#10, 1#12G

1" C, W/FIBER

ULS

LE

2

P3

GATE OPERATOR

TSP-2

LE

C10

1" C, W/ MFGR'S CABLES

MFR'S CABLE

VALVE

ACTUATOR

VA-2

GATE ACCESS

PEDESTAL

M

SOUTH

VALVE VAULT

WET WELL

C10

FROM MAIN

DISTRIBUTION

SWITCHBOARD "A"

CAT6

TSP-4

EXISTING

EXISTING

RECYCLE WATER

CONTROL PANEL

GOLF COURSE PUMP PANEL

EXISTING

RTU R

EXISTING RECYCLE WATER

PUMP CONTROL PANEL

EXISTING

1" C, 3#10, 1#10 G

EXISTING

VALVE ACTUATOR VA-1

VALVE ACTUATOR VA-2

FIT-1

FIT-2

FIT-3

FIT

1

FIT

2

FIT

3

GOLF COURSE

VINEYARDS

1"C W/ANTENNA CABLE

EXISTING C, 3#6, 1 #10 G

TRUCK FILL

SUMBPMP-1

VFD

EXISTING C, 3#6, 1 #10 G

40

HP

MWTS

MWTS

RW

PUMP 1

3/4" C, 2#10, 1#12G

40

HP

RW

PUMP 2

RADIO

ANTENNA

2" C, W/ MFGR'S CABLES

2" C, W/ MFGR'S CABLES

3/4" C, 3#12, 1#12 G

1

HP

C6

CHLORINE SAMPLE PUMP

C6

TSP-1

C2

P2

TRUCK FILL

STATION

FE

1

MAG METER

FE

2

MAG METER

STAINLESS STEEL

GROUNDING

RINGS WITH

STRAPS (TYP)

FE

FE

3

AIT

AE

1

STAINLESS STEEL

GROUNDING

RINGS WITH

STRAPS (TYP)

FE

7.5

HP

HACH CL-17

MAG METER

LSL

1

SUBPMP-1

EMERGENCY

PUMP OFF

MOUNTED PER

AE

CL

STAINLESS STEEL

GROUNDING

RINGS WITH

STRAPS (TYP)

FE

1

E-505

Reuse of Documents

Drawn

This document and the ideas and designs incorporated

herein, as an instrument of professional service, is the

property of GHD Inc. and shall not be reused in whole or

in part for any other project without GHD Inc.'s written

authorization. © GHD Inc. 2012

FINAL TOWN REVIEW NFC

100% SUBMITTAL

No

1/7/14

5/24/13

Revision

Plot Date:

Note: * indicates signatures on original issue of drawing or last revision of drawing

27 November 2013 - 2:32 PM

Plotted by: Ben Langston

Drawn

Job

Project

Manager Director

Cad File No:

Date

N:USSanta RosaProjects12027 - The Town of Yountville12027-11-001 Recycled Water Expansion Project06-CADSheets1202711001 E-200.dwg

MTC

Designer JF

Client

Project

Design

Check

Drafting

Check

GHD Inc.

2235 Mercury Way Suite 150 Santa Rosa California 95407 USA

T 1 707 523 1010 F 1 707 527 8679

W www.ghd.com

Approved

(Project Director)

JANUARY 2014

Date

Scale

NONE

This Drawing shall not be used

for Construction unless Signed

and Sealed For Construction

Title

Contract No.

Original Size

E-200

Sht

34

of

50](https://image.slidesharecdn.com/recycledwaterprojectdraftplansandspecifications-131226163747-phpapp02/85/Recycled-water-project-draft-plans-and-specifications-33-320.jpg)

![30 AMP

L1

VFD

480VAC

3ɸ

7.5

HP

L2

MWTS

SEAL

24" MIN.

L3

R1A

R1

VFD

RUN

R1B

R2A

R2

VFD

FAIL

ENCLOSURE

AIR

CONDITIONER

R2B

COMMUNICATIONS

PORT

CPT

480VAC PRIM./

120VAC SEC

TAG:

"GOLF COURSE

PUMP 01"

VFD FAIL

TO RTU R

(STATUS-FAIL)

LCD VFD

CONTROLLER

LCD VFD

CONTROLLER

FIT-1

1

LSL-1

CRA-1

CRLSL-1

FROM RTU R

(LOW LEVEL

INTERLOCK)

A

STOP

START

xoo

oox

CRP1-1

(CONTROL-AUTO)

oox

RESET

A

ANALOG INPUT

4-20mA

(CONTROL-SPEED)

TO RTU

(STATUS-AUTO)

A

(CONTROL-HAND)

S

S-1

MWTS

R

40" MIN.

H

RUN

SEAL

FAIL

120 VAC

O

4-20mA INPUT

LC-150 CONTROLLER

(CONTROL-SPEED)

STOP

START

FIT-2

HAND

LOCAL-OFF

AUTO

VFD [R1]

R

R1B

'RUN'

1

RUN

R1A

M1-1

TO RTU R

(STATUS-RUN)

M1

ENDRESS

+HAUSER

WALL MOUNT

METER (TYP)

TAG:

"CHLORINE SAMPLE

PUMP"

INSTALL SLAB, UNISTRUT,

AND CABINET AS SHOWN

SEAL FAIL

MDR

RUN

CONNECT TO

SEAL FAIL

LEADS

MDR-1

CR

MST

1

CRMST-1

A

R

GOLF COURSE PUMP 01

PANEL LOCATION

ALARM

A

FIT-3

HAND OFF

SCALE : NTS

'SEAL FAIL'

1

CR

TSH

NC

CRTSH-1

30A

MCP

OL

L1

TR

TSH

MWTS

M-1

GOLF COURSE PUMP PANEL

INNER DOOR LAYOUT

1

HP

120VAC

1Ø

NTS

CLPMP

L2

TRTSH-1

A

CR

A

RESET

CRMST-2

'MWTS'

'RESET'

1

COMMON ALARM

SHUTDOWN

TRTSH-2

1

CRA-2

TO RTU R

(ALARM-SHUTDOWN)

CRPL-2

OL

CRA-1

MFGR'S CABLE

(TYP)

FIT

1

M-3

TO RTU R

(STATUS-RUN)

M-2

DRAWING NOTES:

1

DEVICE/COMPONENT IS LOCATED IN FIELD. REFER

TO APPROPRIATE PLAN FOR LOCATION.

FIT

2

'RUN'

R

'RESET'

CRA1-1

CRA1-2

TO RTU R

(OVERLOAD ALARM)

SYSTEM COMPONENTS: REFER TO SPECIFICATIONS

FOR ADDITIONAL CONTROL COMPONENTS AND

ACCESSORIES REQUIRED FOR EACH PANEL.

FIT

3

1

PROVIDE A SINGLE AIR CONDITIONER UNIT SIZED

FOR PUMP CONTROL PANEL HEAT REQUIREMENTS.

GOLF COURSE PUMP PANEL 01

'OVERLOAD ALARM'

A

PROVIDE GROUND FAULT EQUIPMENT PROTECTOR

RATED BREAKER (GFEP).

OL

PROVIDE AND INSTALL CONCRETE SLAB TO SUPPORT NEW PANEL AS

SHOWN. SLAB SHALL BE MAXIMUM 6'-0” WIDE BY 6'-0” LONG, AND SHALL

HAVE A DEPTH OF 8”. SLAB SHALL BE REINFORCED WITH #4 STEEL

BARS AT 12” O.C. EACH WAY, PLACED CENTRALLY IN SLAB. SLAB TO BE

EMBEDDED 6” INTO EXISTING GRADE. REFER TO SHEET S-100 FOR

FURTHER NOTES RELATED TO CONCRETE AND STEEL DETAILING

CHLORINE SAMPLE PUMP ELEMENTARY

NTS

TYP

CLPMP 1

CLPMP 2

NTS

Reuse of Documents

Drawn

This document and the ideas and designs incorporated

herein, as an instrument of professional service, is the

property of GHD Inc. and shall not be reused in whole or

in part for any other project without GHD Inc.'s written

authorization. © GHD Inc. 2012

FINAL TOWN REVIEW NFC

100% SUBMITTAL

No

1/7/14

5/24/13

Revision

Plot Date:

Note: * indicates signatures on original issue of drawing or last revision of drawing

27 November 2013 - 2:34 PM

Plotted by: Ben Langston

Drawn

Job

Project

Manager Director

Cad File No:

Date

N:USSanta RosaProjects12027 - The Town of Yountville12027-11-001 Recycled Water Expansion Project06-CADSheets1202711001 E-300.dwg

MC

Designer JF

Client

Project

Drafting

Check

GHD Inc.

2235 Mercury Way Suite 150 Santa Rosa California 95407 USA

T 1 707 523 1010 F 1 707 527 8679

W www.ghd.com

Design

Check

Approved

(Project Director)

JANUARY 2014

Date

Scale

NONE

This Drawing shall not be used

for Construction unless Signed

and Sealed For Construction

Title

Contract No.

Original Size

E-300

Sht

35

of

50](https://image.slidesharecdn.com/recycledwaterprojectdraftplansandspecifications-131226163747-phpapp02/85/Recycled-water-project-draft-plans-and-specifications-34-320.jpg)