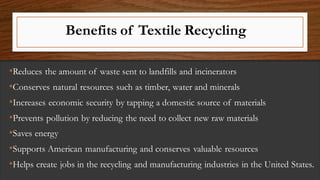

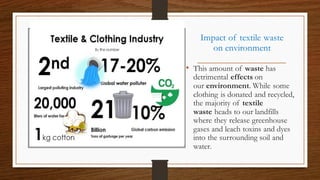

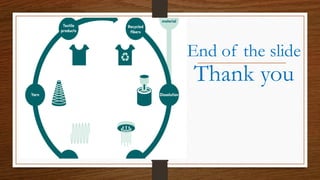

Cotton recycling prevents unnecessary waste and can provide a more sustainable alternative to disposal. Recycled cotton comes from sources like secondhand clothing or textile waste that is sorted by color then shredded and spun into new yarns and fabrics. The majority of recycled cotton undergoes mechanical recycling where fabrics are sorted and shredded into yarn and fiber.