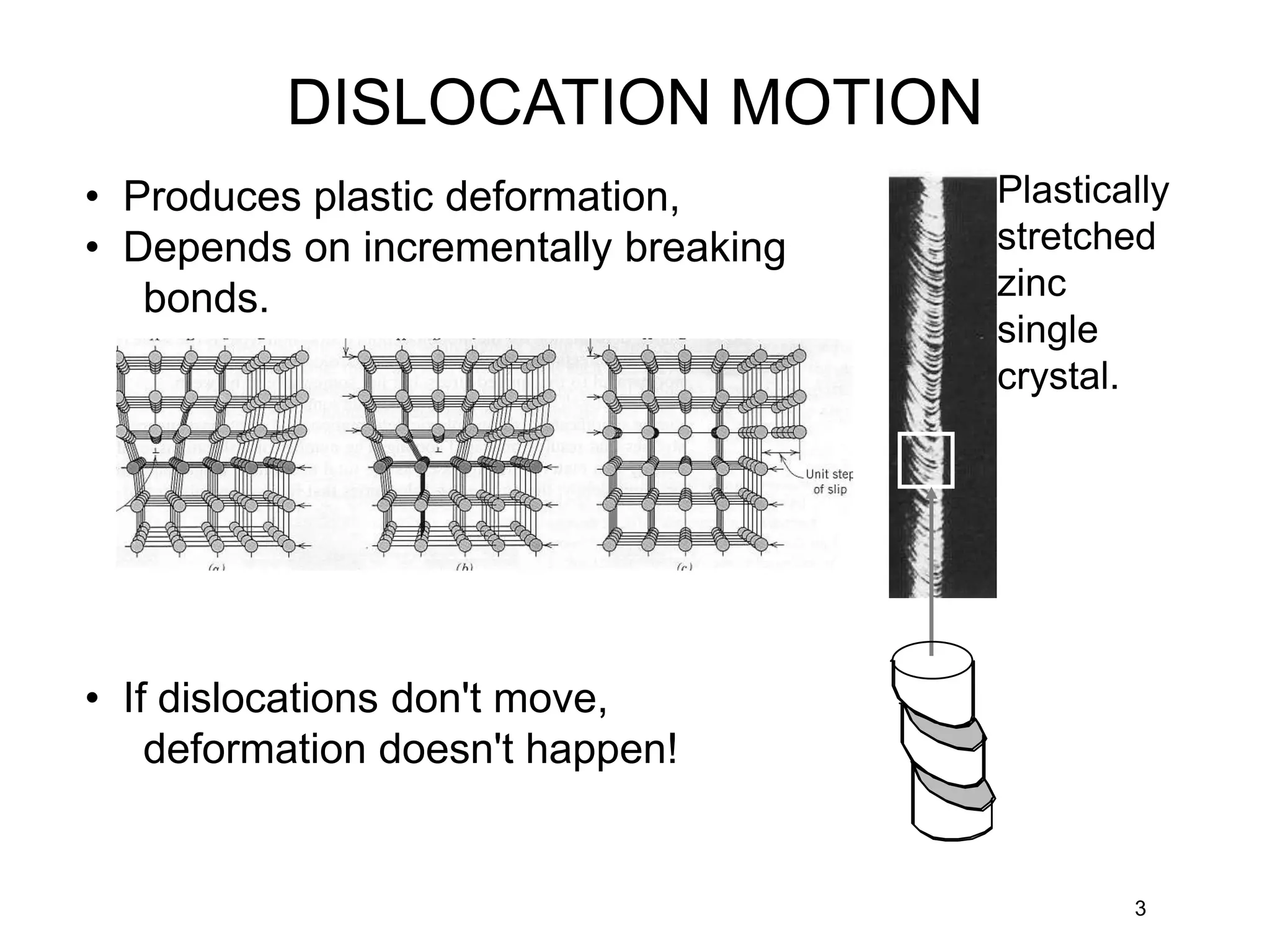

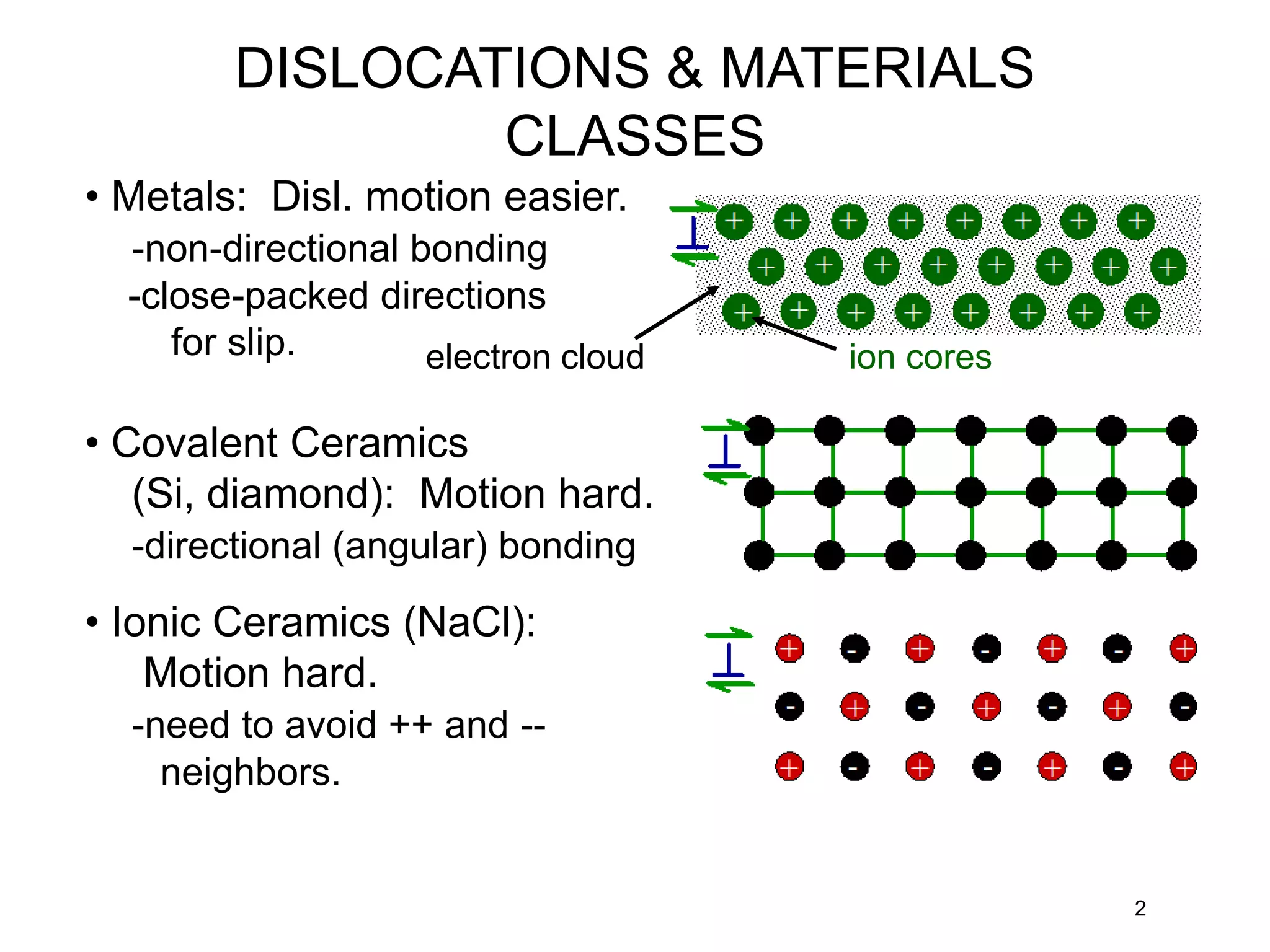

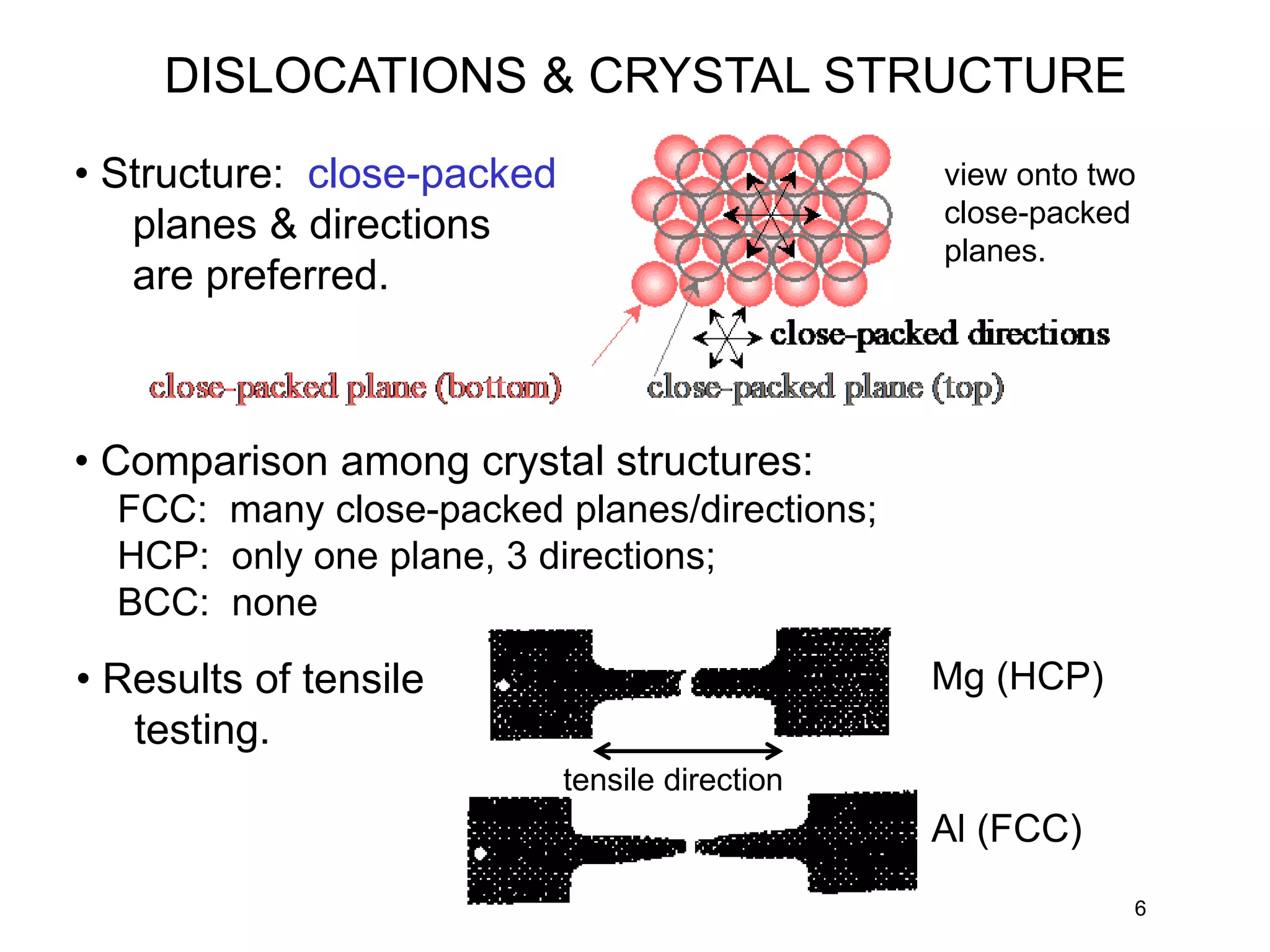

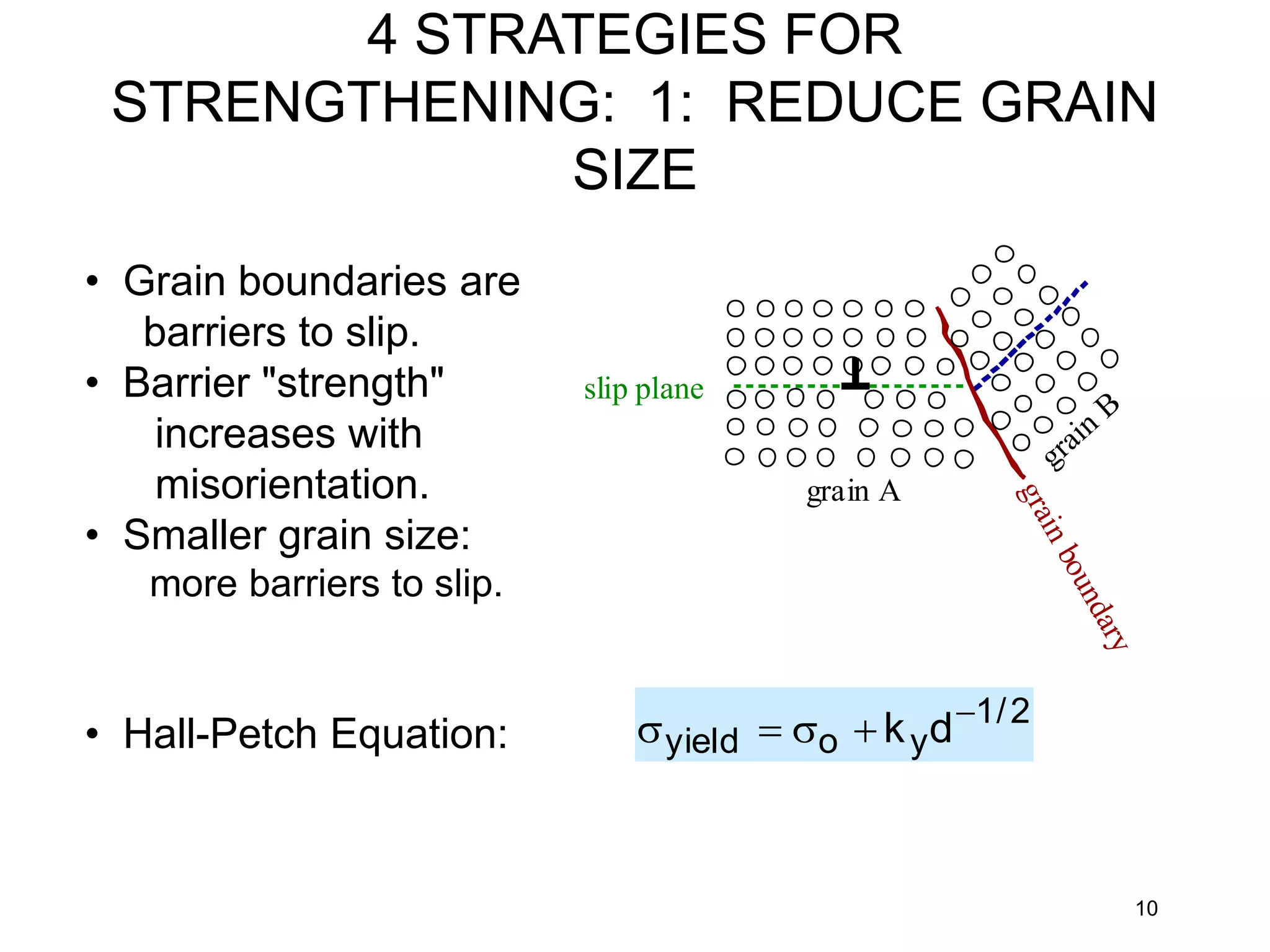

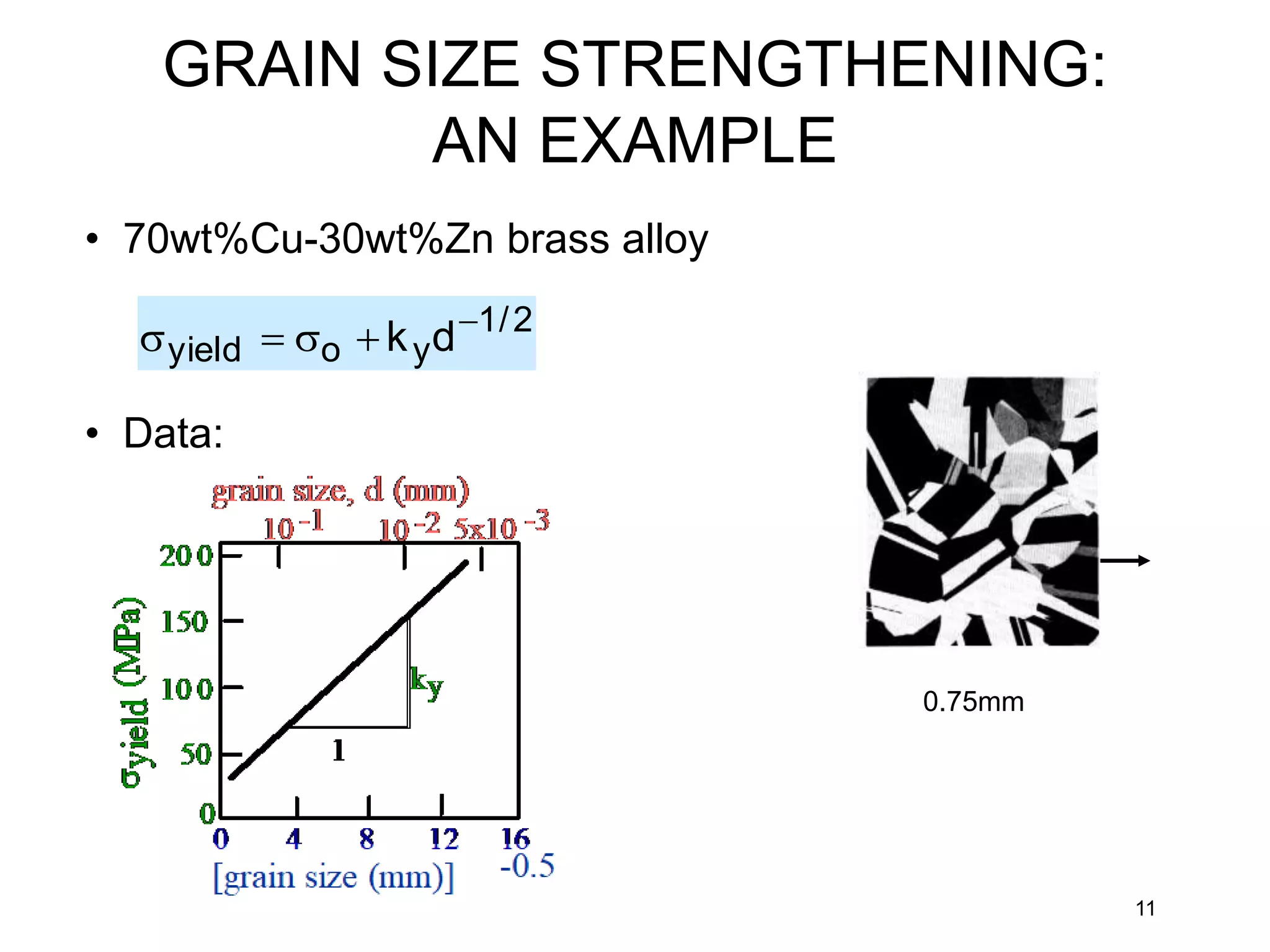

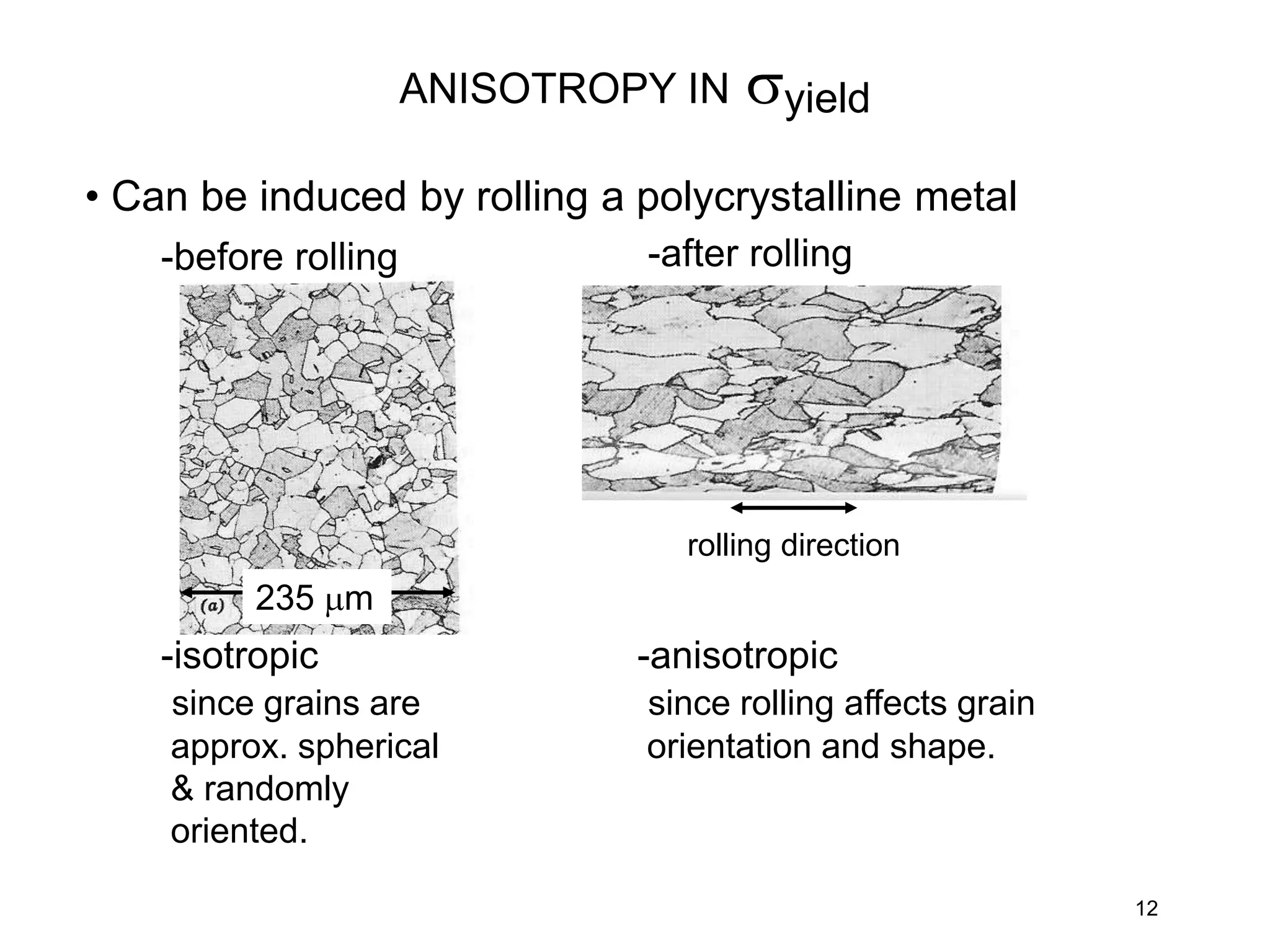

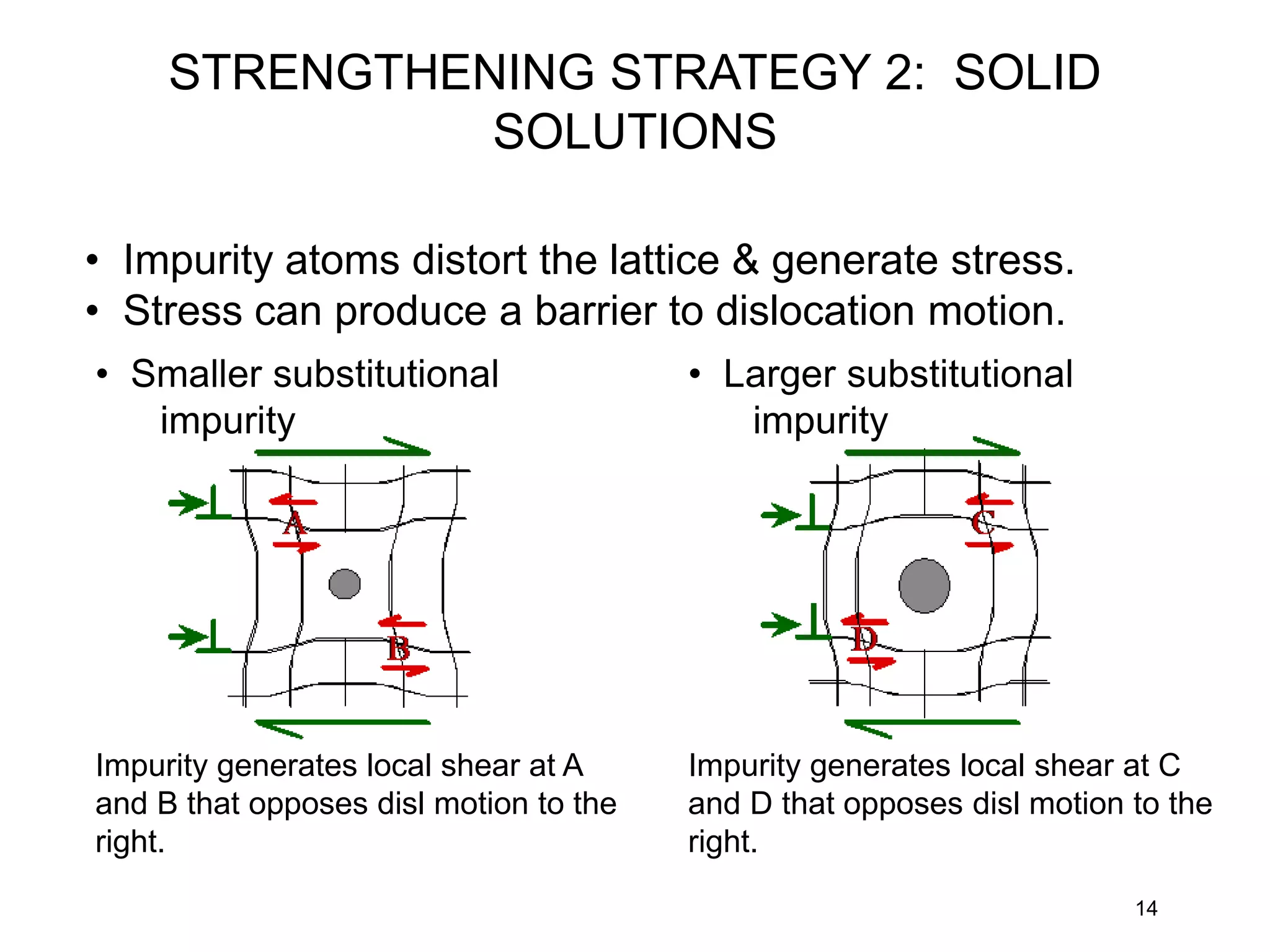

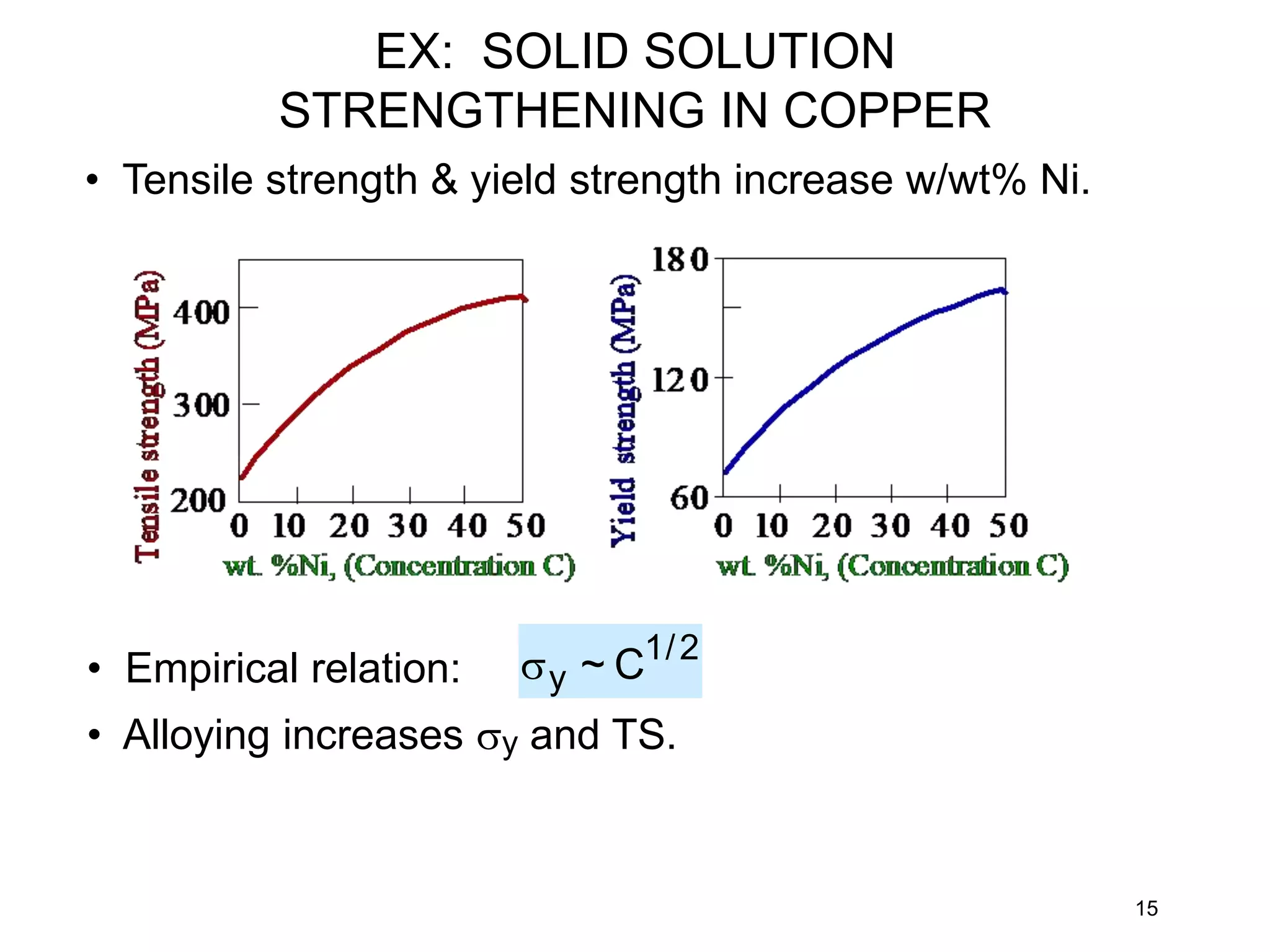

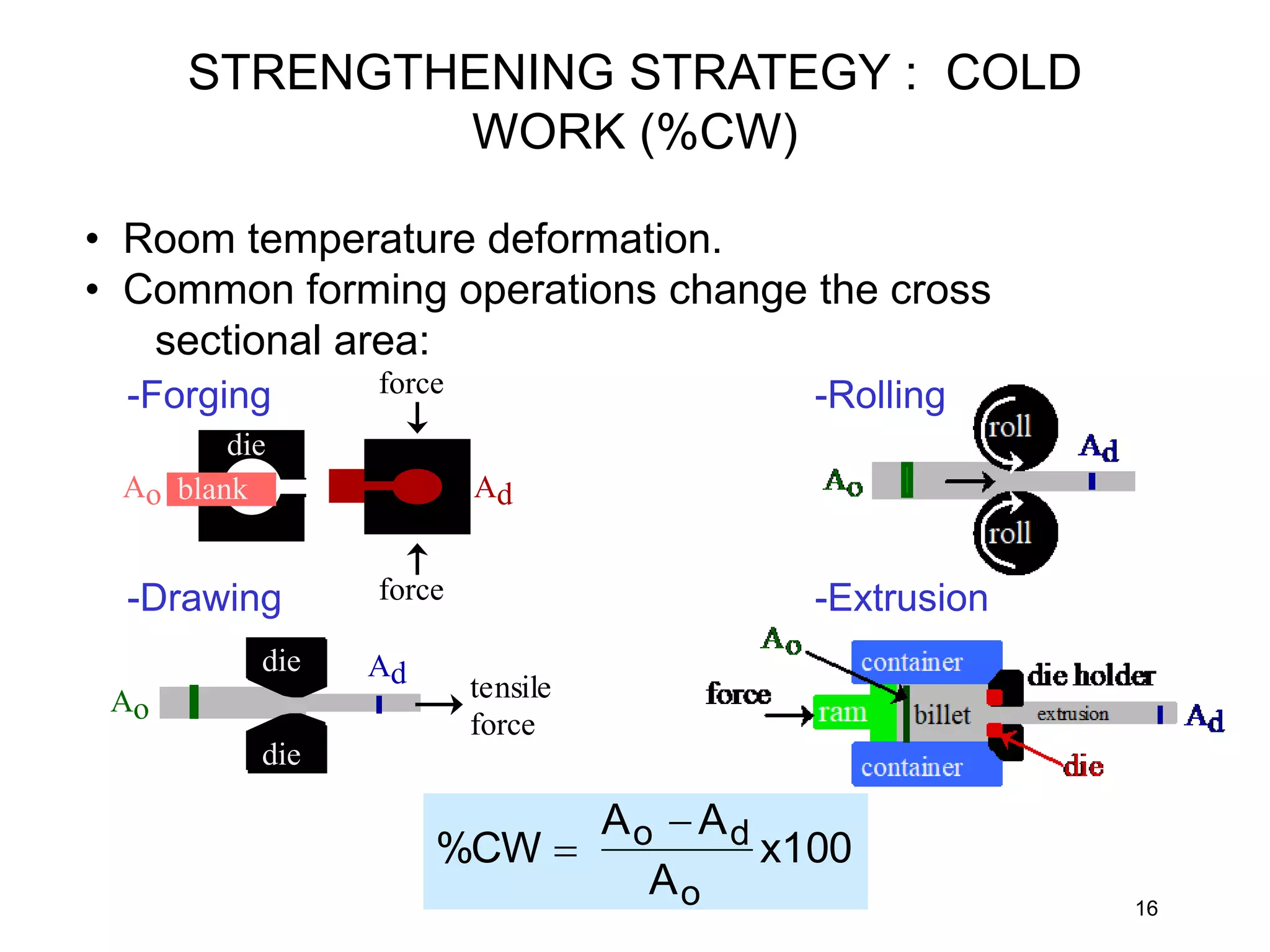

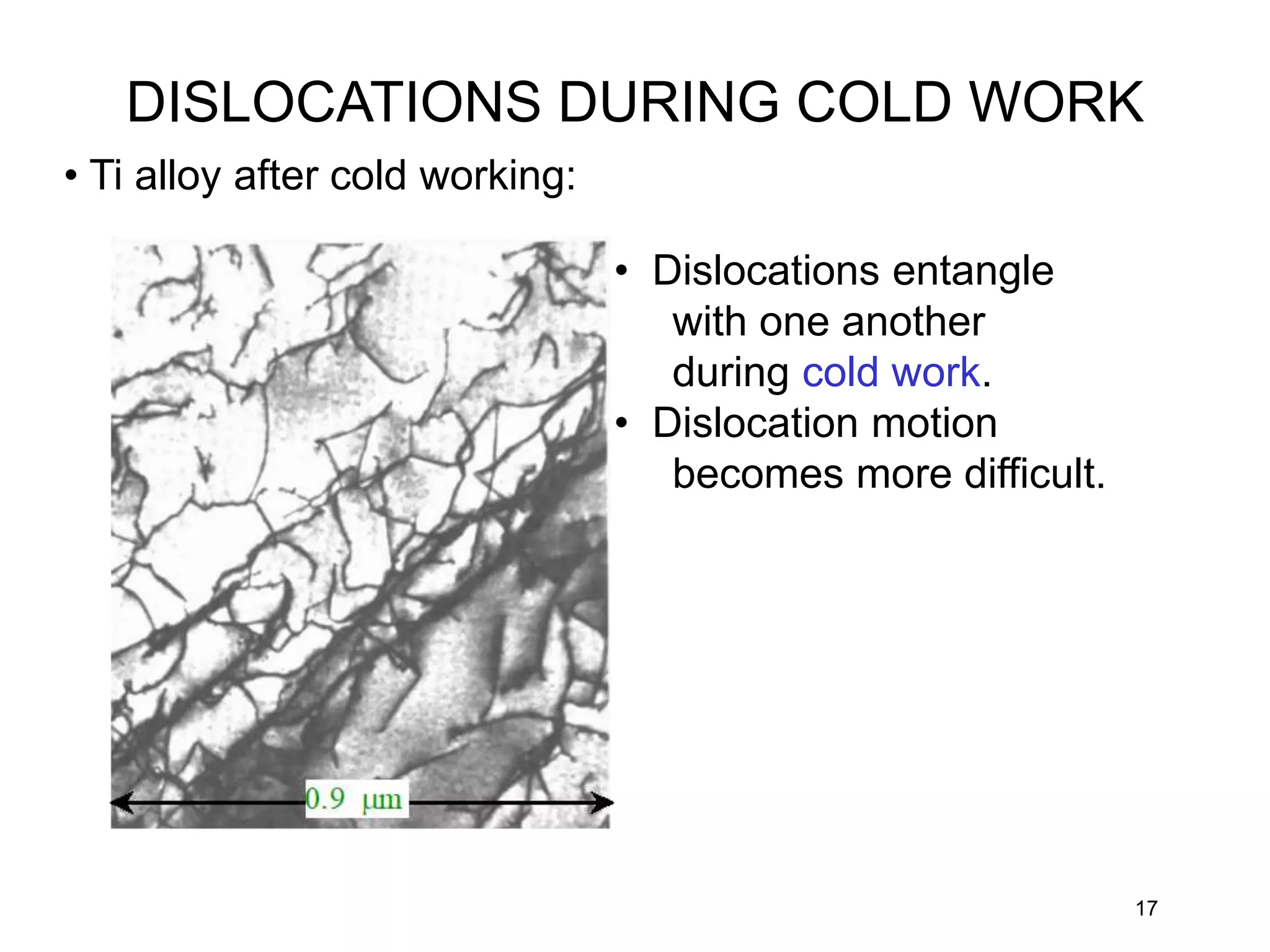

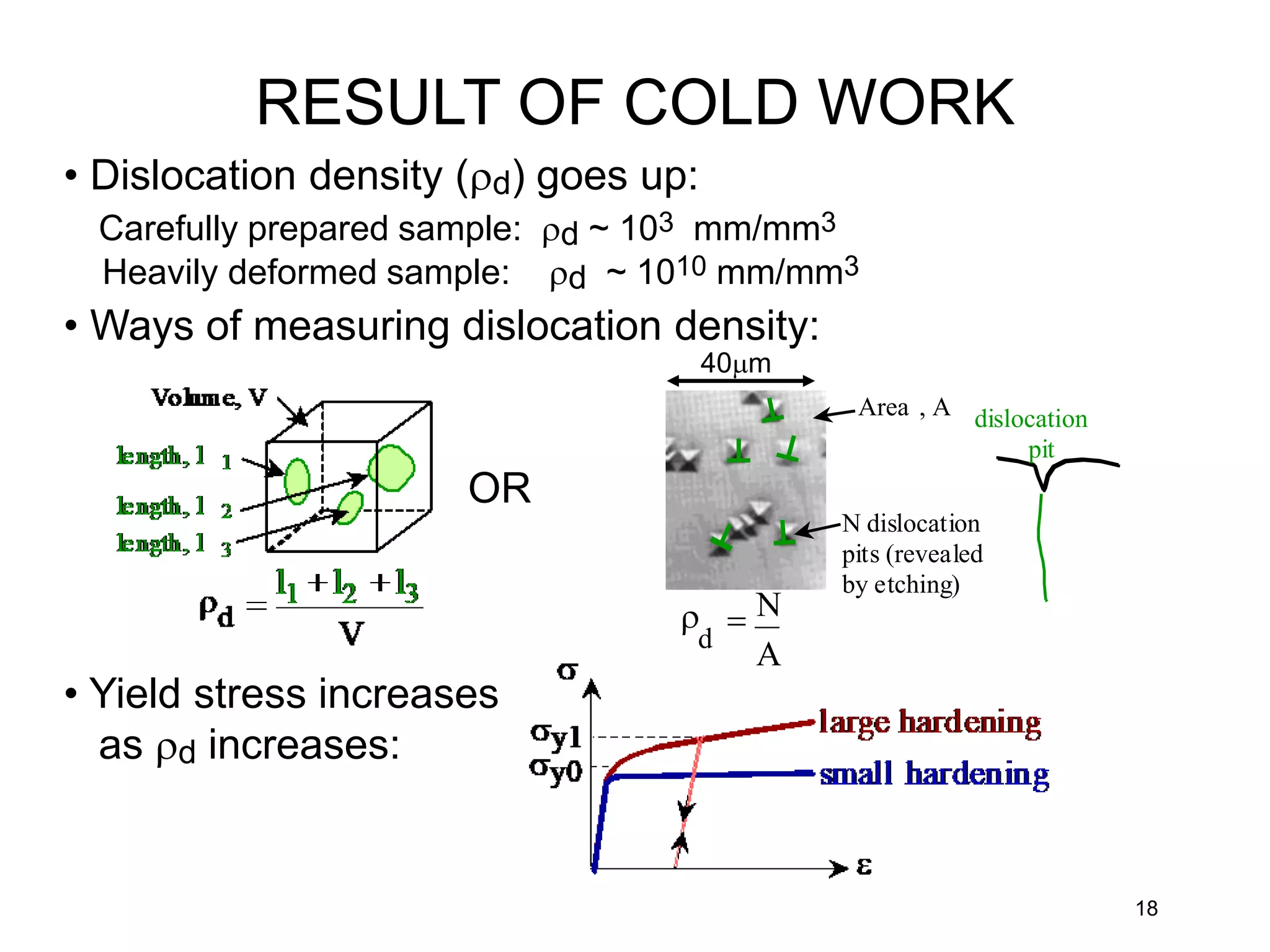

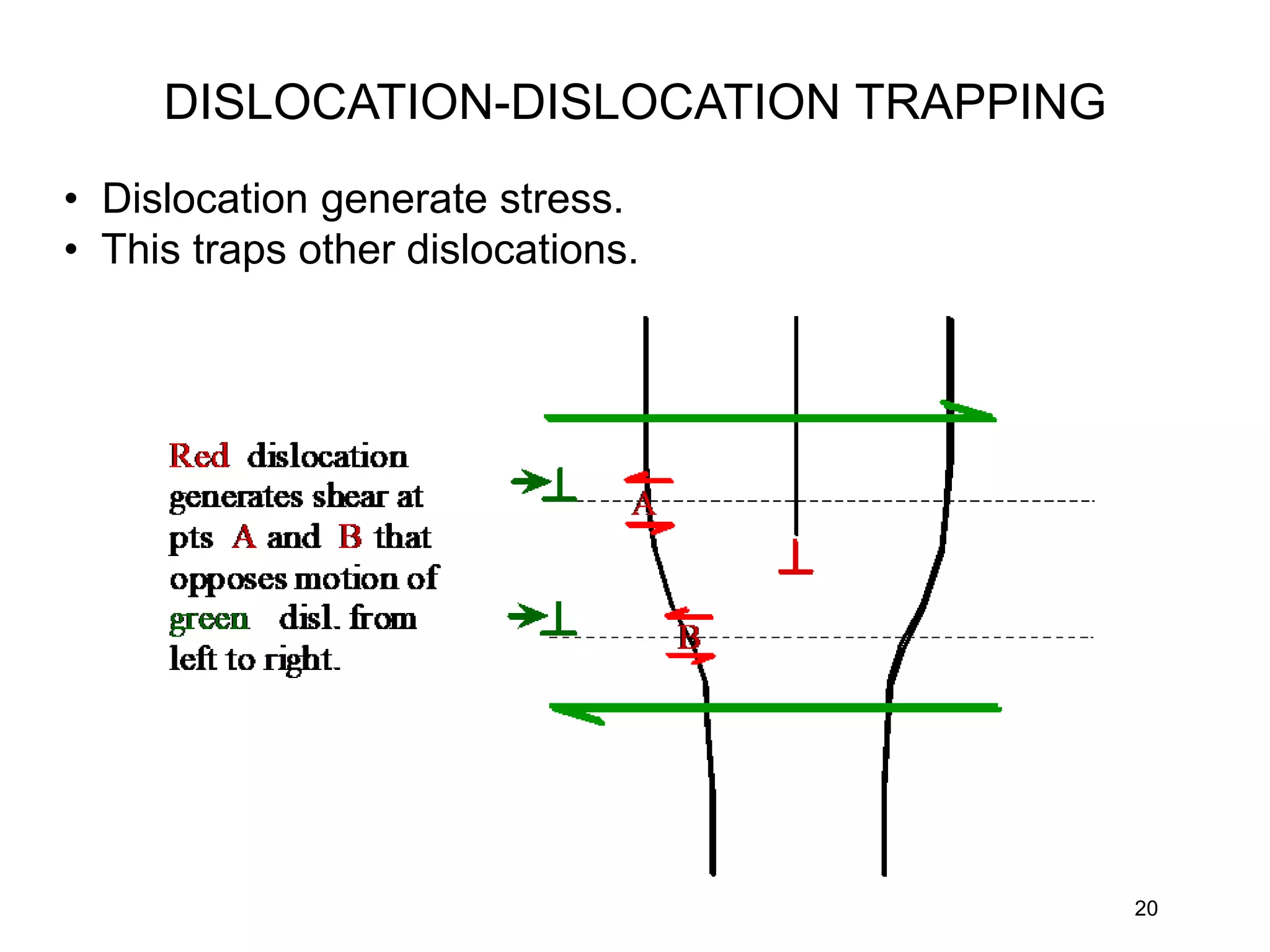

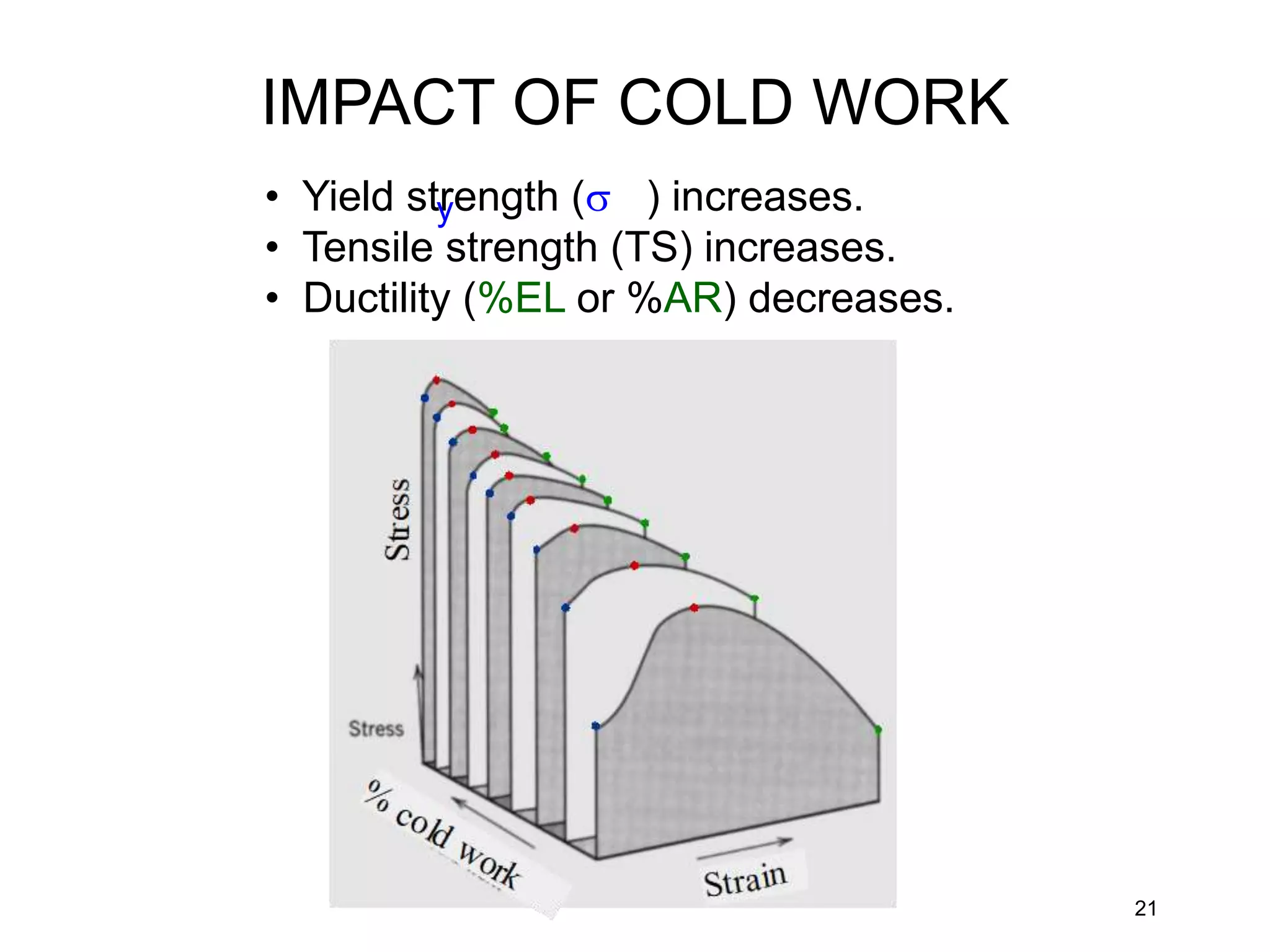

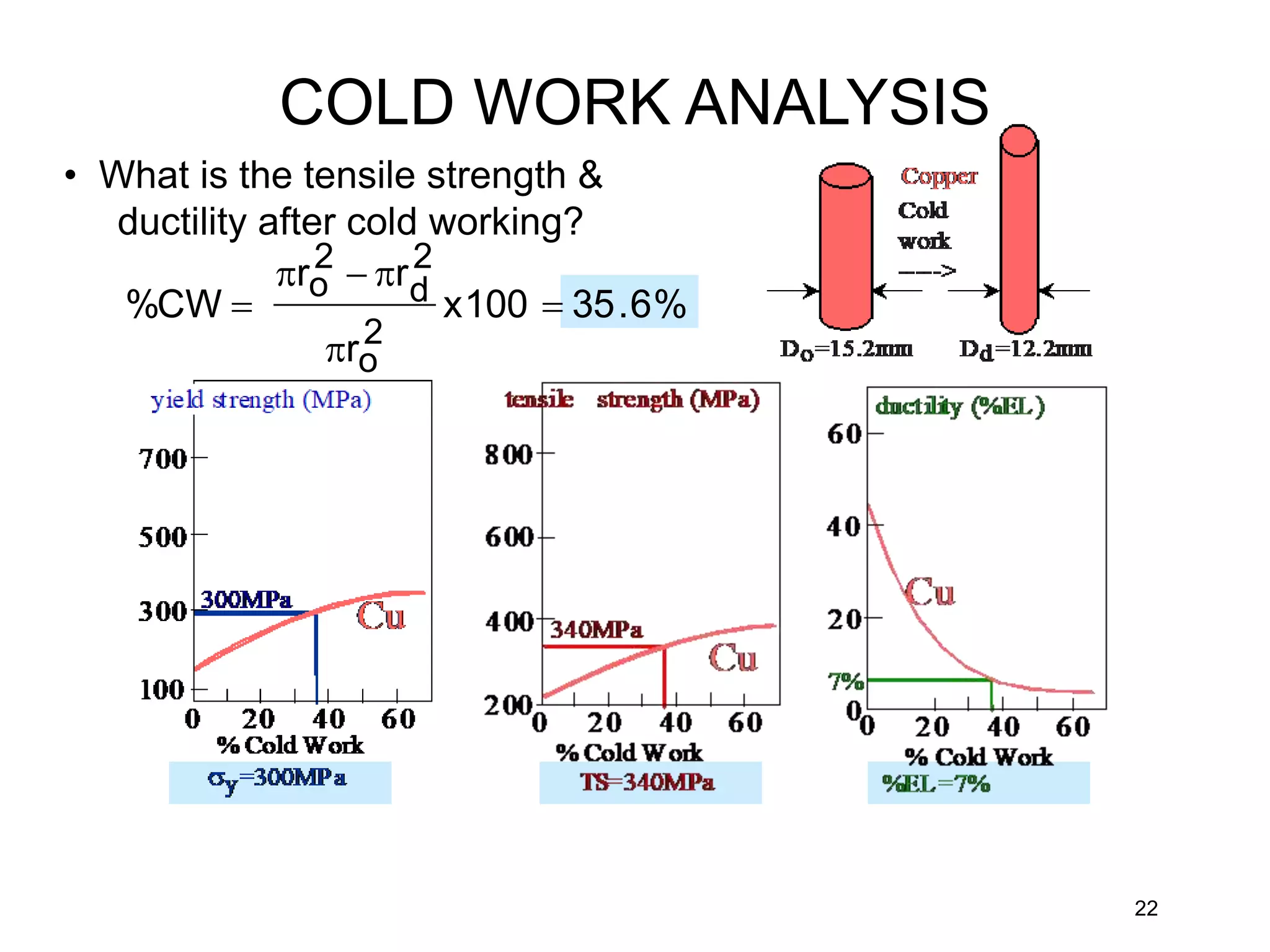

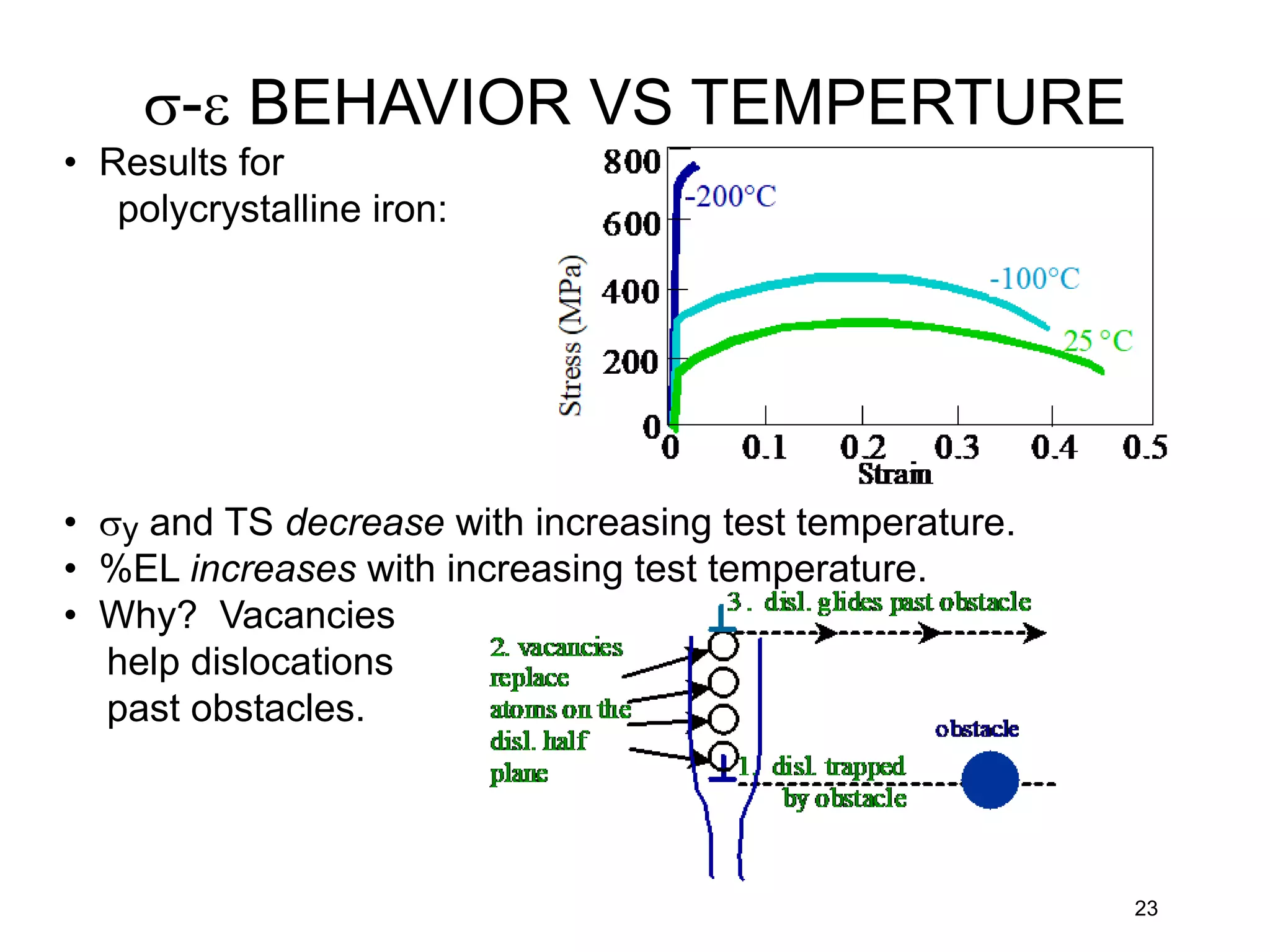

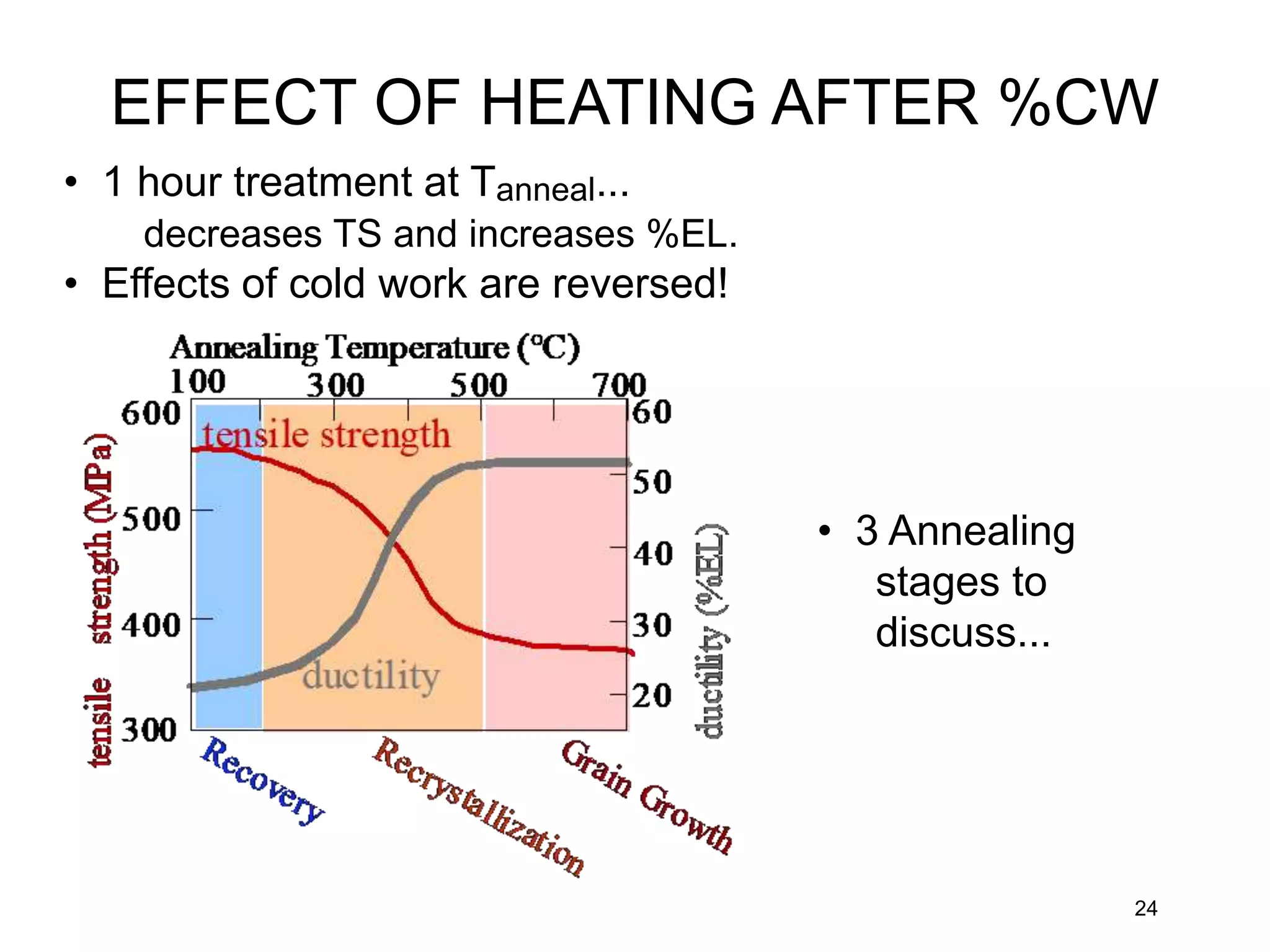

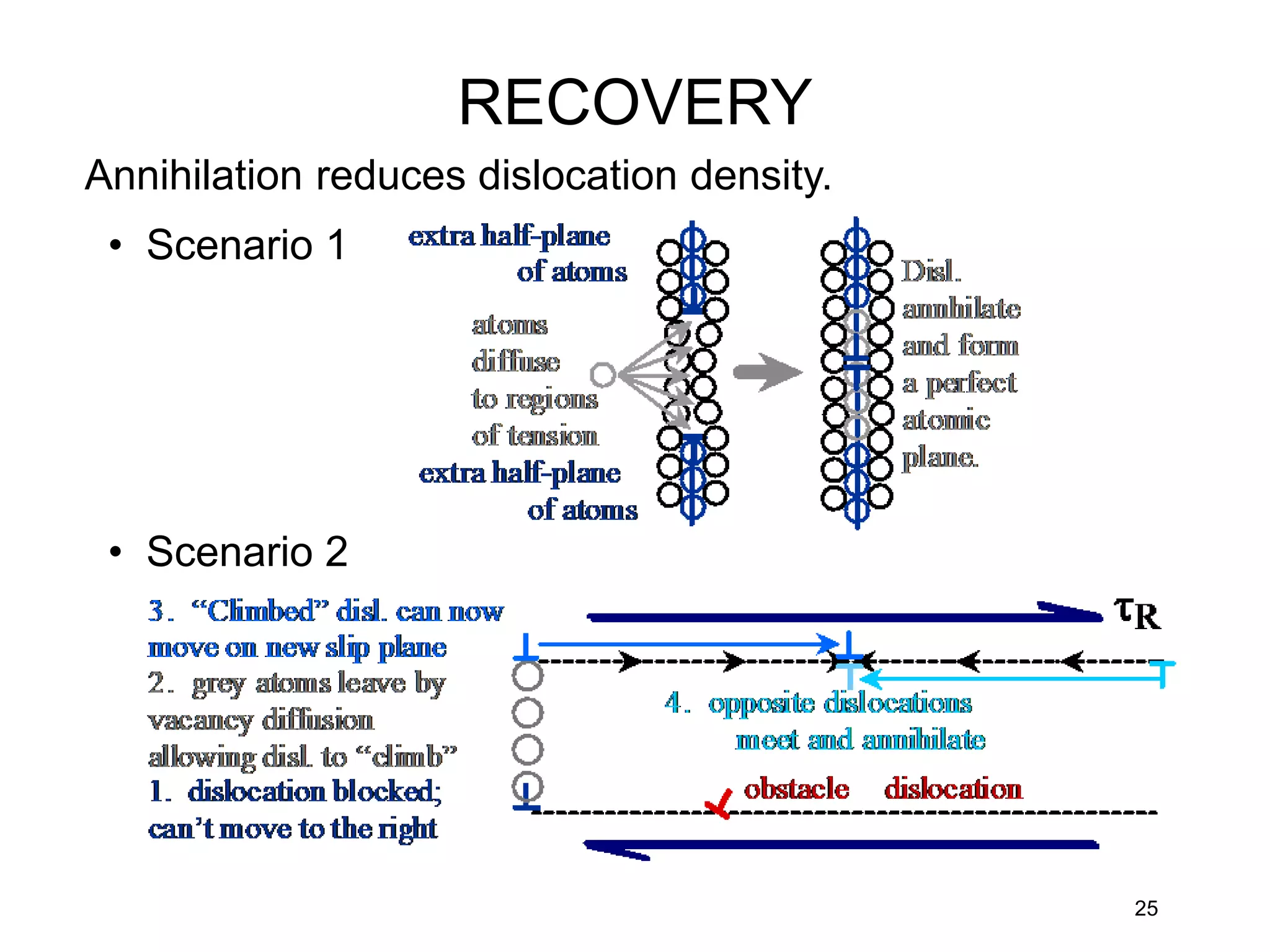

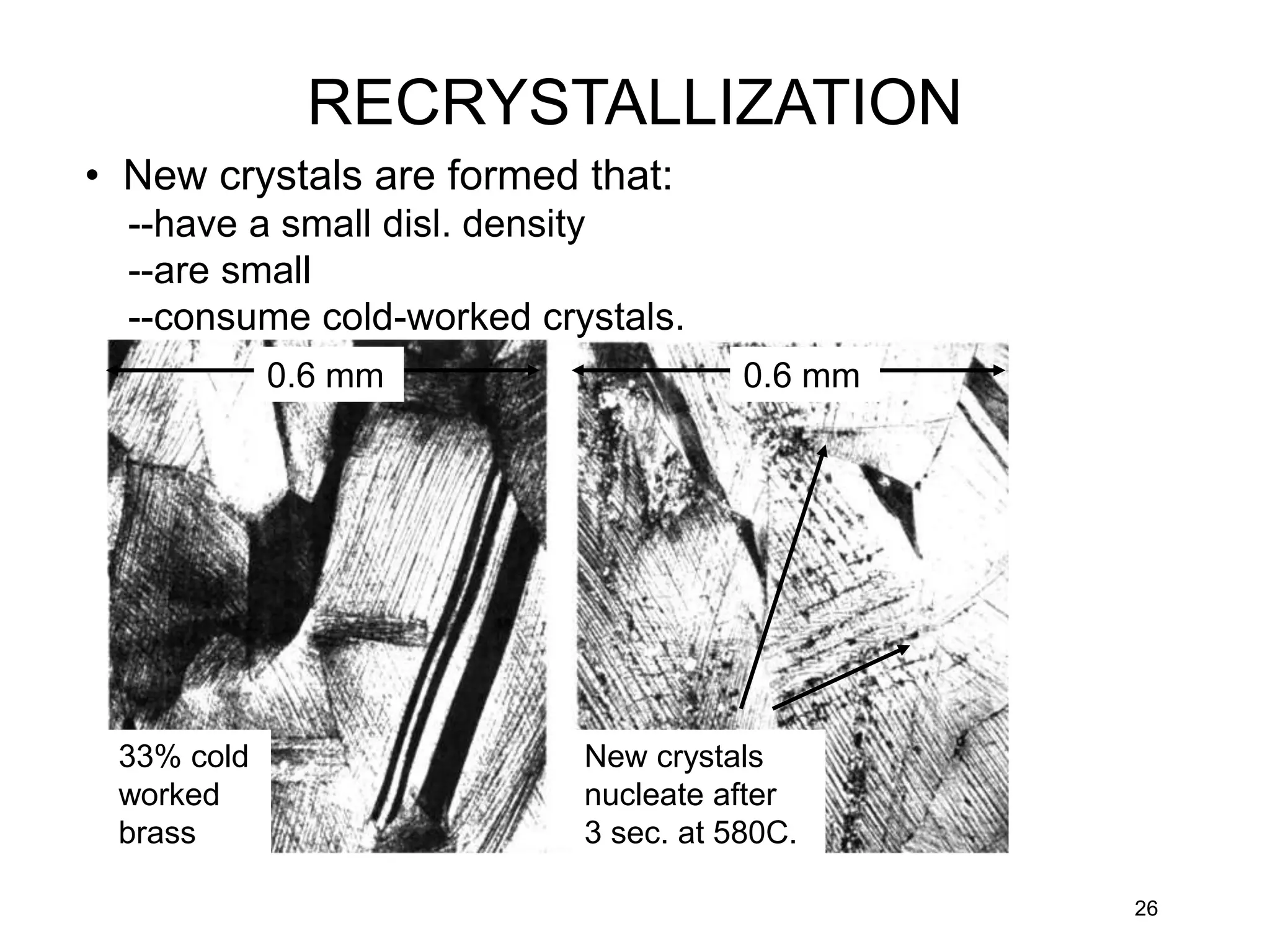

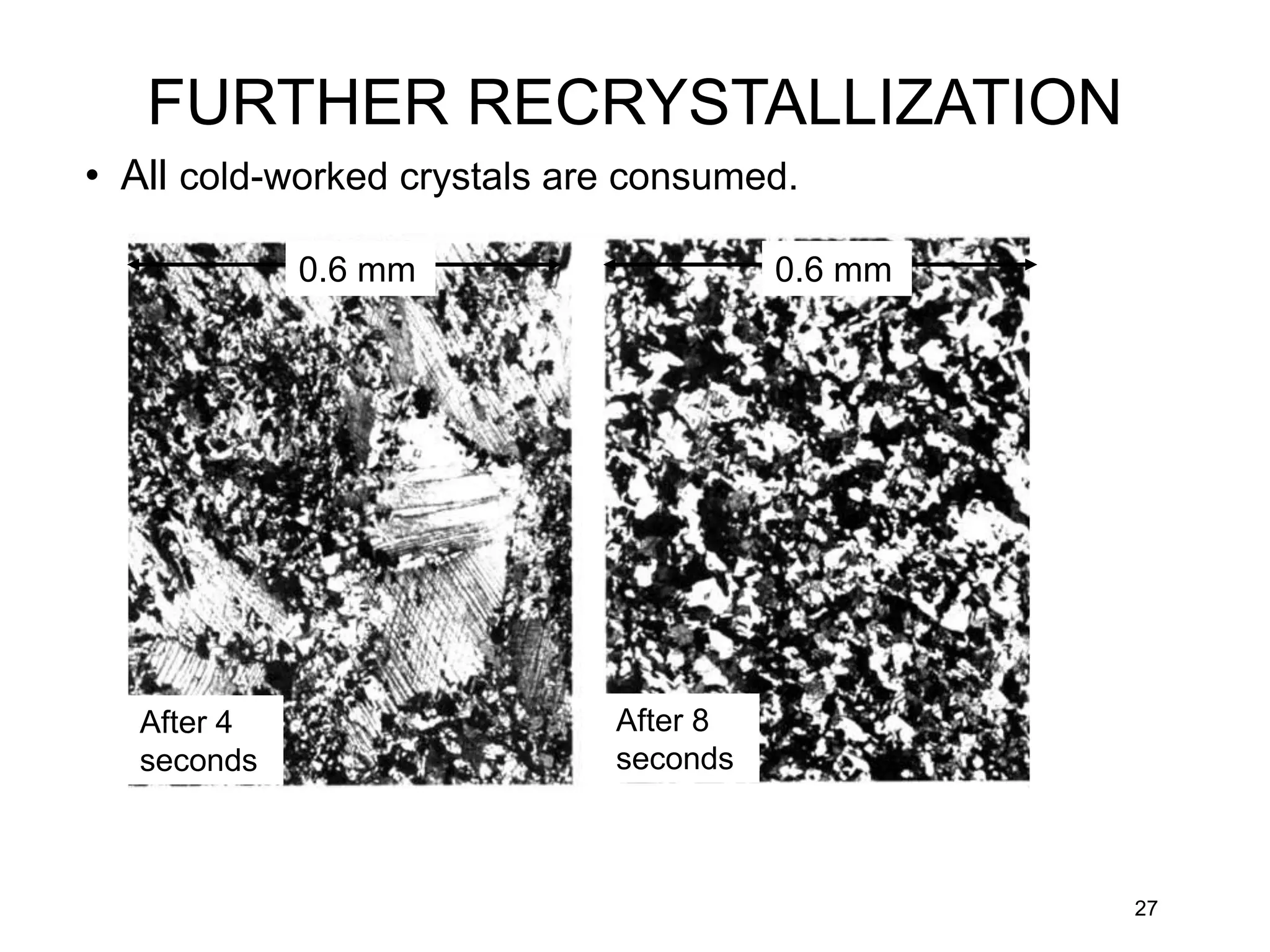

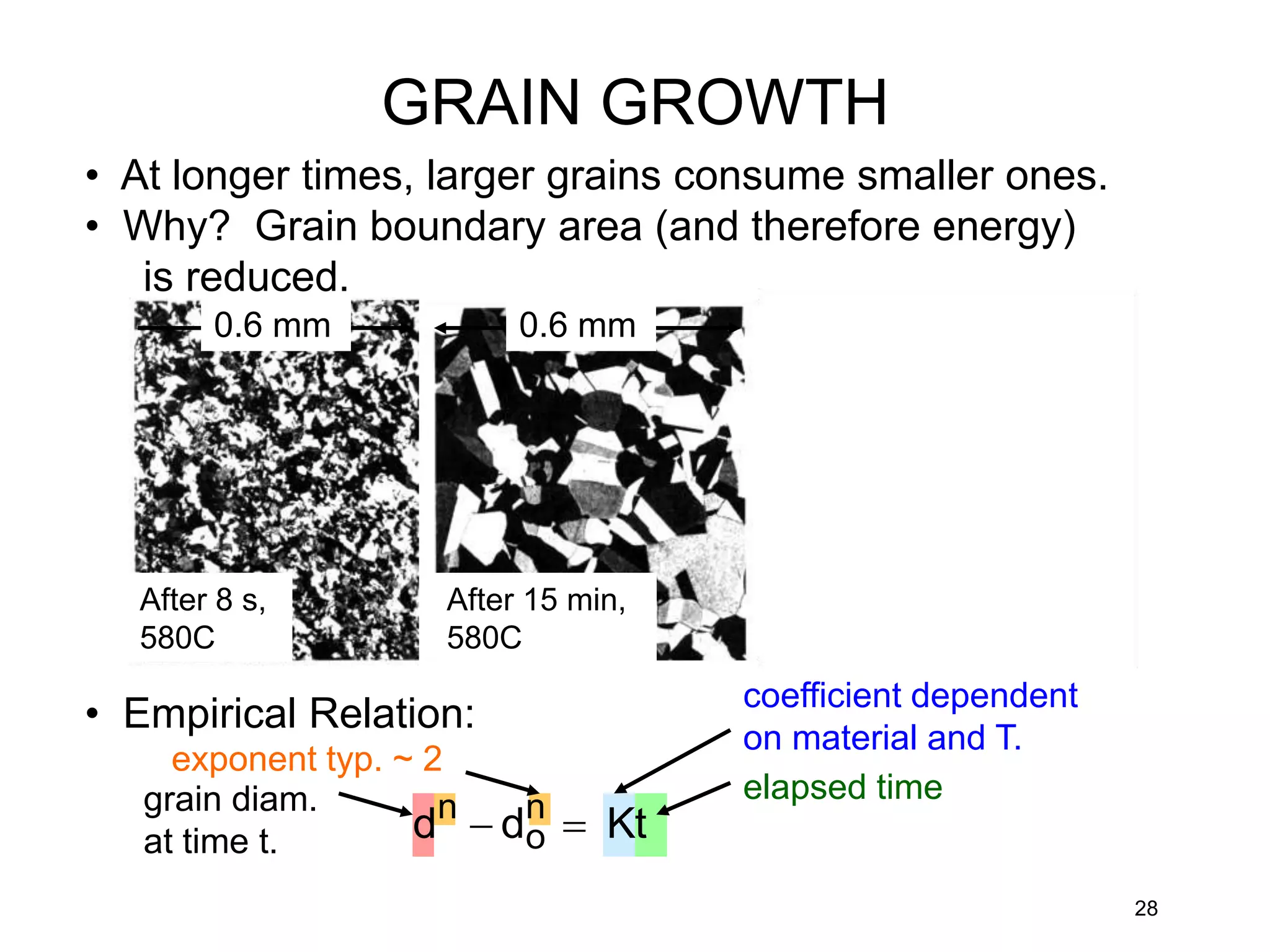

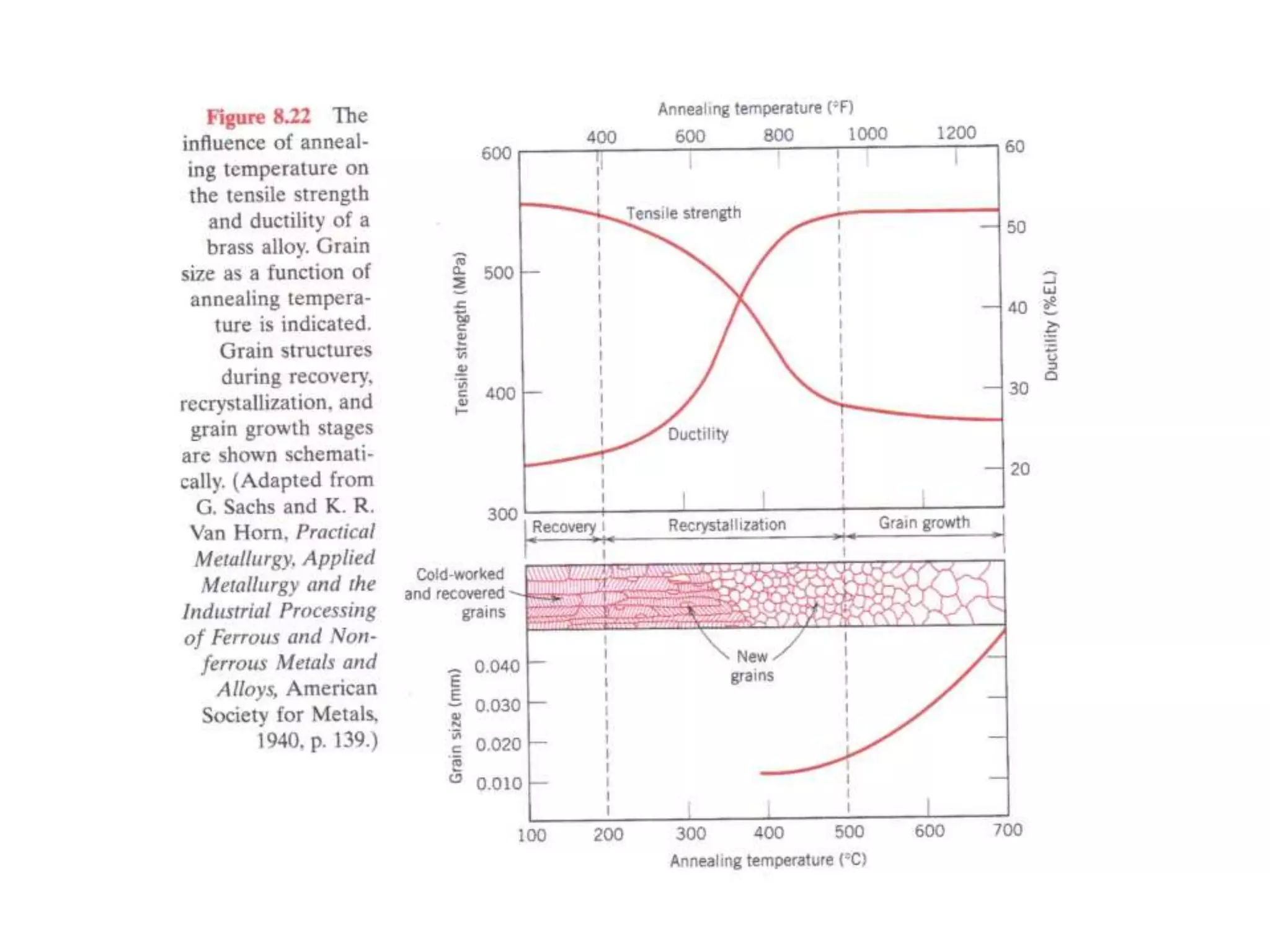

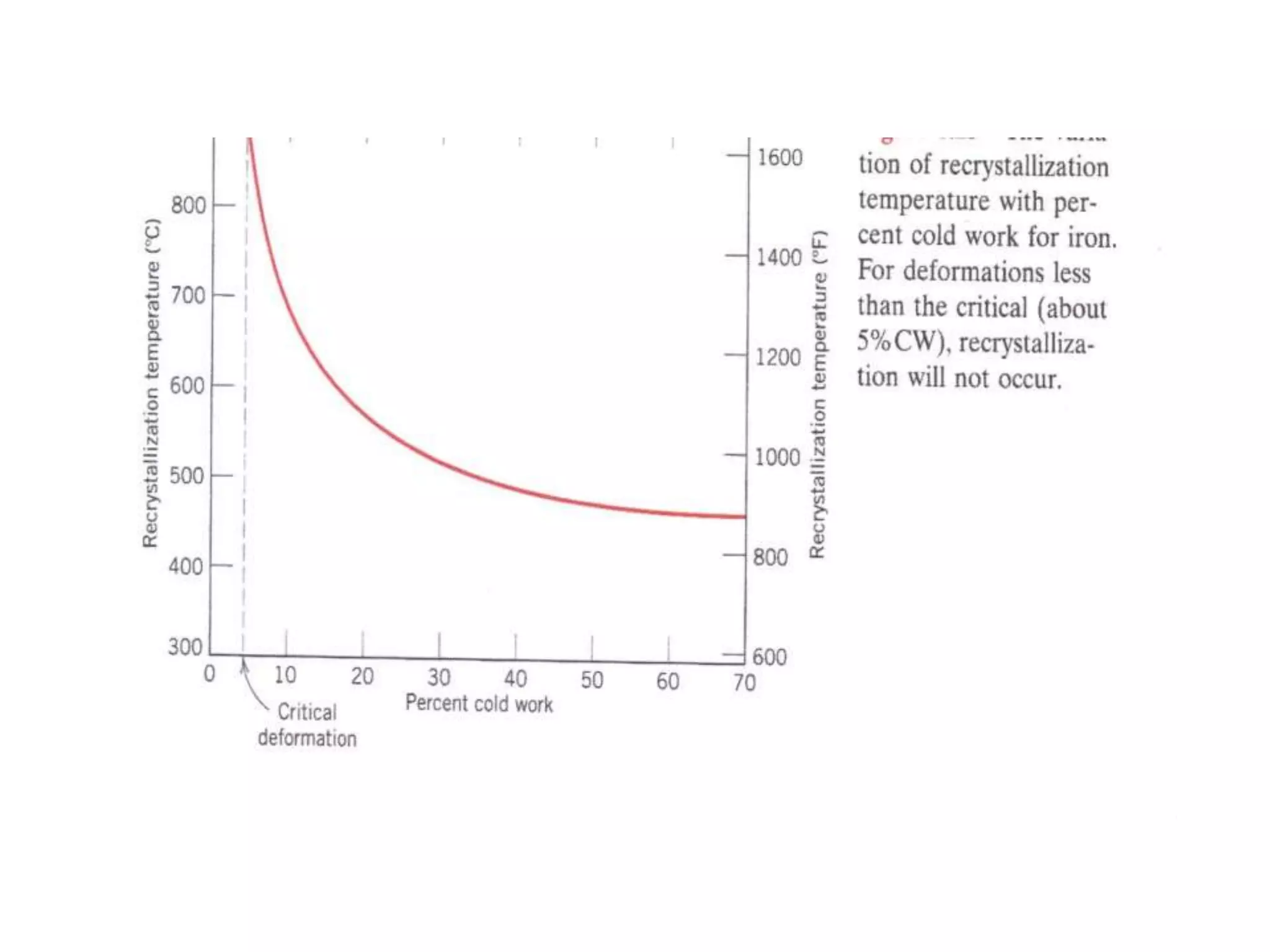

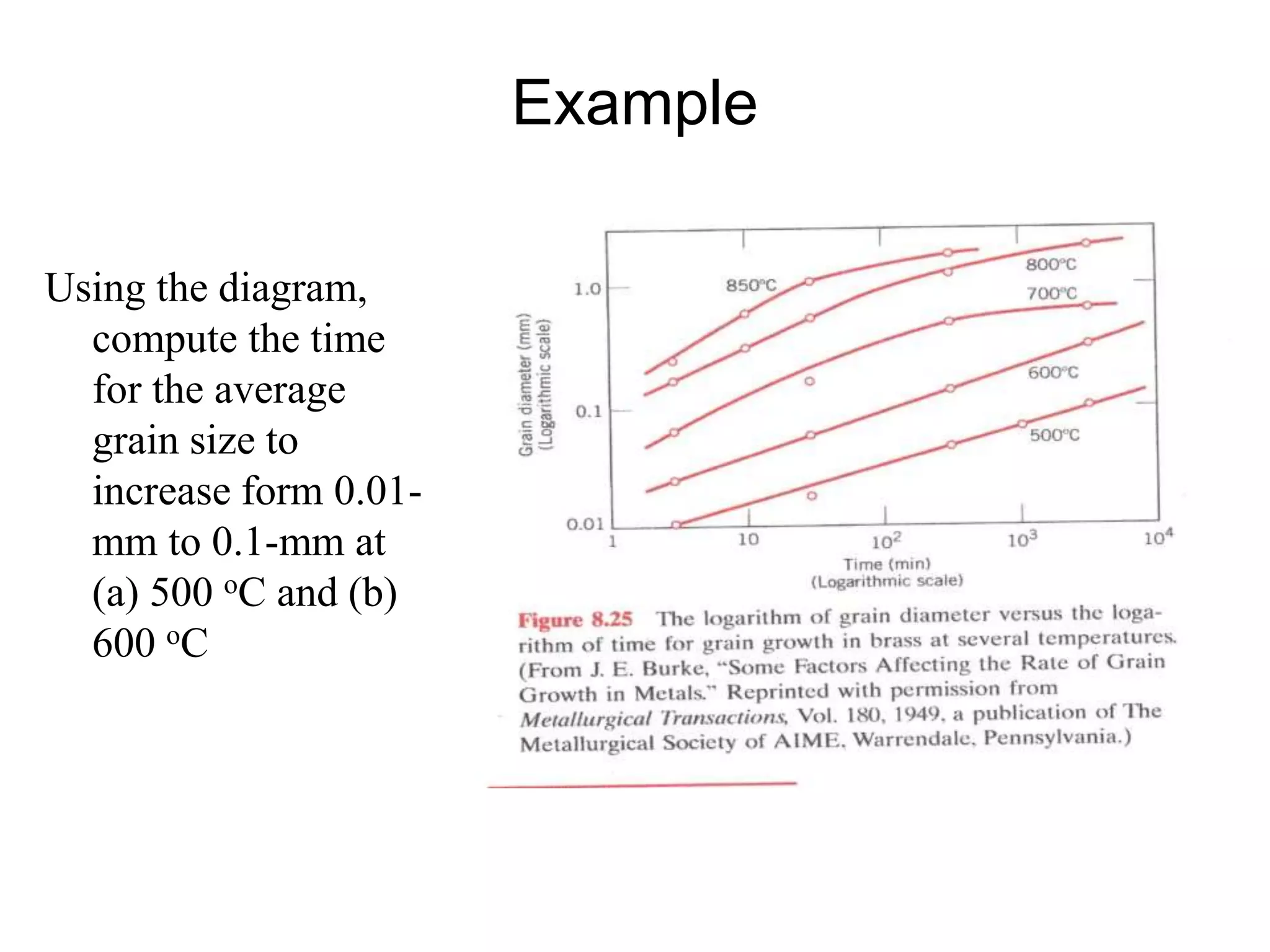

Dislocations are observed primarily in metals and alloys because the metallic and ionic bonding allows for easier dislocation motion compared to covalent and directional bonding in ceramics. Strength is related to dislocation motion, with higher strength occurring when dislocation motion is impeded. Key ways to increase strength discussed are decreasing grain size, solid solution strengthening, precipitate strengthening, and cold working, all of which make dislocation motion more difficult. Heating can reduce strength by allowing recovery processes like dislocation annihilation and recrystallization, which reduce dislocation density and increase grain size.